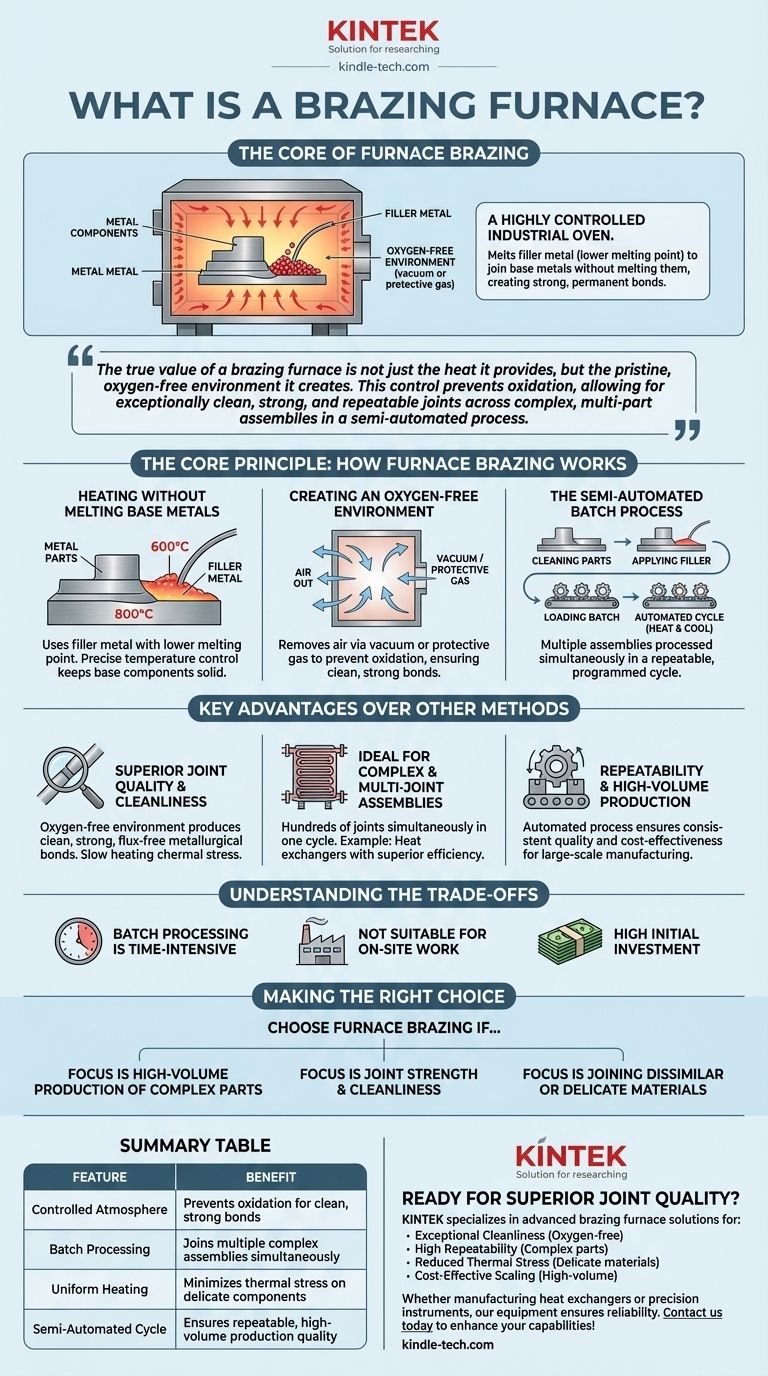

At its core, a brazing furnace is a highly controlled industrial oven designed to join metal components together. It works by heating an assembly so that a specialized filler metal, which has a lower melting point than the base metals, melts and flows into the joints. As the assembly cools, this filler solidifies, creating a strong, permanent metallurgical bond without melting the components themselves.

The true value of a brazing furnace is not just the heat it provides, but the pristine, oxygen-free environment it creates. This control prevents oxidation, allowing for exceptionally clean, strong, and repeatable joints across complex, multi-part assemblies in a semi-automated process.

The Core Principle: How Furnace Brazing Works

Furnace brazing is more than simple heating; it is a precise, multi-stage process engineered for reliability and quality. Understanding its mechanics reveals why it is chosen for critical applications.

Heating Without Melting the Base Metals

The foundational principle of brazing is the use of a filler metal with a lower melting point than the parts being joined.

The furnace is programmed to a specific temperature that is high enough to melt the filler but low enough to keep the base components solid. This prevents distortion and damage to the parent materials.

Creating an Oxygen-Free Environment

A successful braze requires perfectly clean metal surfaces. A furnace achieves this by removing the air from its chamber before heating.

This is typically done by creating a vacuum or by purging the chamber with a protective gas. This prevents oxidation, a chemical reaction that would otherwise contaminate the joint and block the filler metal from bonding correctly.

The Semi-Automated Batch Process

Furnace brazing is a batch process, meaning multiple assemblies are processed at once in a repeatable cycle.

The typical workflow involves cleaning the parts, applying the filler metal (often as a paste or pre-formed wire), loading the assemblies into the furnace, and running the automated heating and cooling cycle.

Key Advantages Over Other Joining Methods

Engineers specify furnace brazing when other methods like welding or manual torch brazing cannot meet the requirements for complexity, quality, or scale.

Superior Joint Quality and Cleanliness

Because the entire process occurs in a vacuum or protective atmosphere, the resulting joints are free from oxides and flux residue. This creates exceptionally clean and strong metallurgical bonds.

The slow, uniform heating and cooling also minimizes thermal stress on the components, which is critical for delicate or precision assemblies.

Ideal for Complex and Multi-Joint Assemblies

A furnace can create hundreds of joints on a single, complex assembly in one cycle. This is impossible with manual, joint-by-joint methods.

Heat exchangers are a prime example. The furnace simultaneously bonds all the tubes and fins, resulting in a compact, uniform unit with superior thermal efficiency and a longer service life.

Repeatability and High-Volume Production

Once a furnace cycle is programmed, it can be repeated thousands of times with minimal variation. This makes furnace brazing highly cost-effective for high-volume manufacturing, ensuring every part meets the same quality standard.

Understanding the Trade-offs

While powerful, furnace brazing is not a universal solution. Its nature as a large-scale batch process comes with specific limitations.

Batch Processing is Time-Intensive

Heating an entire furnace chamber and a large batch of parts to brazing temperature—and then cooling it all back down—takes a significant amount of time. The process is not designed for speed or one-off jobs.

Not Suitable for On-Site Work

A brazing furnace is a large, stationary piece of factory equipment. The process cannot be used for on-site installations or repairs, where manual methods like welding or torch brazing are necessary.

High Initial Investment

The equipment itself—the vacuum furnace, control systems, and associated infrastructure—represents a significant capital investment. The process is only cost-effective when the production volume justifies the initial expense.

Making the Right Choice for Your Application

Selecting furnace brazing depends entirely on your project's goals for quality, complexity, and scale.

- If your primary focus is high-volume production of complex parts: Furnace brazing is the superior choice for its ability to create multiple clean joints simultaneously with high repeatability.

- If your primary focus is joint strength and cleanliness: The controlled, oxygen-free environment of a brazing furnace prevents oxidation and produces metallurgical bonds that are often stronger and more reliable than those from other methods.

- If your primary focus is joining dissimilar or delicate materials: The uniform, gentle heating of furnace brazing reduces thermal stress, making it ideal for dimensionally critical components or joining metals with different properties.

Ultimately, furnace brazing empowers engineers to design and manufacture robust, intricate, and highly reliable components at scale.

Summary Table:

| Feature | Benefit |

|---|---|

| Controlled Atmosphere | Prevents oxidation for clean, strong bonds |

| Batch Processing | Joins multiple complex assemblies simultaneously |

| Uniform Heating | Minimizes thermal stress on delicate components |

| Semi-Automated Cycle | Ensures repeatable, high-volume production quality |

Ready to achieve superior joint quality in your metal assemblies?

KINTEK specializes in advanced brazing furnace solutions that deliver:

- Exceptional cleanliness with oxygen-free environments

- High repeatability for complex, multi-joint components

- Reduced thermal stress for delicate materials

- Cost-effective scaling for high-volume production

Whether you're manufacturing heat exchangers, precision instruments, or other critical components, our lab equipment expertise ensures your brazing process meets the highest standards of reliability and efficiency.

Contact us today to discuss how KINTEK's brazing solutions can enhance your manufacturing capabilities!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency