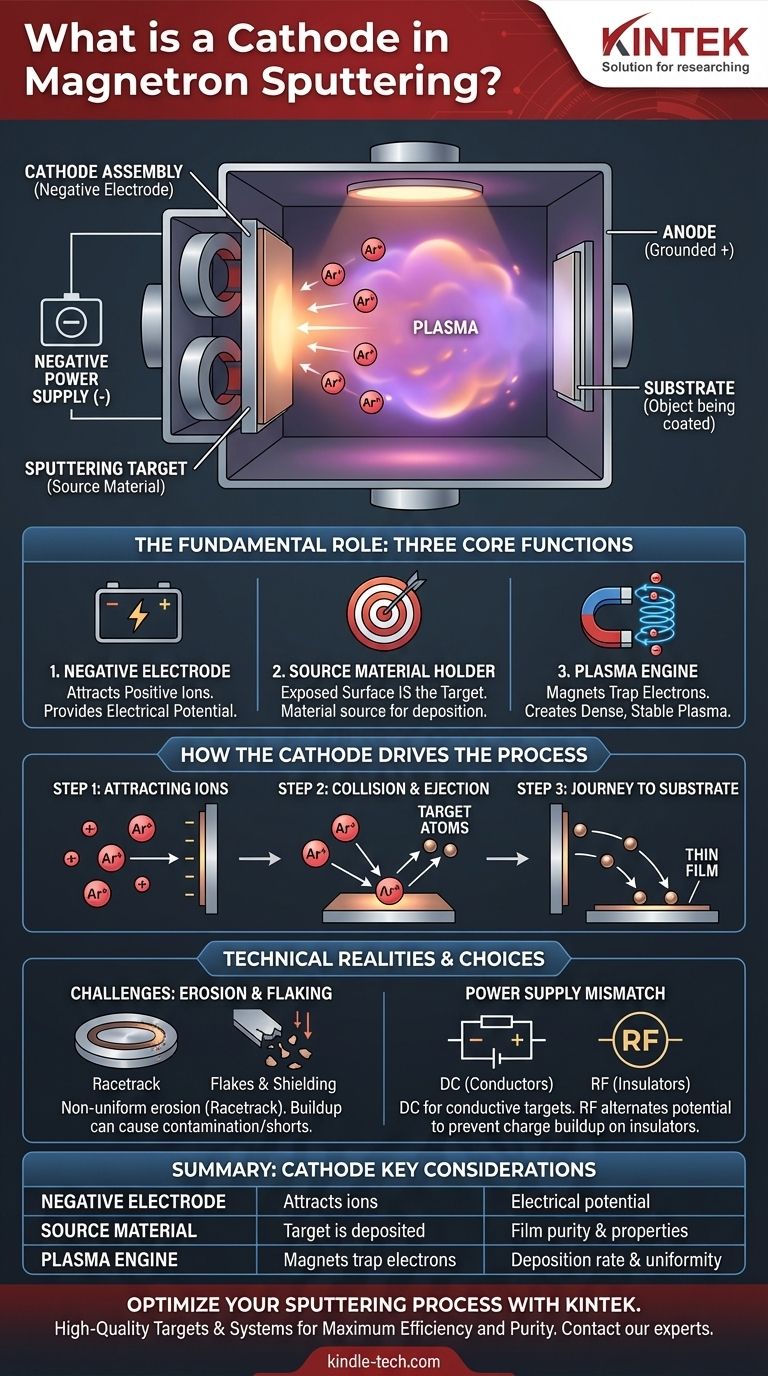

In magnetron sputtering, the cathode is the negatively charged electrode whose exposed surface is the sputtering target. This target is the source material—such as titanium, silicon, or gold—that you intend to deposit as a thin film. The cathode assembly is not just an electrical component; it is the heart of the deposition process, holding the source material and working with a magnetic field to generate the plasma required for sputtering.

The critical concept to grasp is that the cathode and the target are functionally intertwined. The cathode provides the electrical potential and magnetic field structure, while its surface is the target from which atoms are physically ejected and deposited onto your substrate.

The Fundamental Role of the Cathode

To understand magnetron sputtering, you must first understand the three core functions of the cathode assembly. It serves as an electrode, a material source, and the engine for creating a highly efficient plasma.

The Negative Electrode

In any DC circuit, there is a positive terminal (anode) and a negative terminal (cathode). In a sputtering system, the chamber walls are typically the grounded anode, while the cathode is connected to a negative power supply. This electrical potential difference is what drives the entire process.

The Source Material Holder (The Target)

This is the most crucial point of clarification. The material you wish to deposit, known as the sputtering target, is physically mounted onto the cathode structure. Therefore, the exposed face of the cathode is the target. When we say we are sputtering a target, we are sputtering the surface of the cathode.

The Engine of Plasma Generation

The "magnetron" part of magnetron sputtering refers to the magnets placed behind the target within the cathode assembly. This magnetic field traps electrons near the face of the cathode, dramatically increasing the probability that they will collide with and ionize neutral gas atoms (typically Argon). This creates a dense, stable plasma precisely where it's needed: directly in front of the target.

How the Cathode Drives the Sputtering Process

The cathode's electrical and magnetic properties initiate a clear chain of events that results in thin film deposition.

Step 1: Attracting Positive Ions

The sputtering chamber is filled with a low-pressure inert gas like Argon. The system's power supply and magnetic field ignite this gas into a plasma, which is a soup of positive Argon ions (Ar+) and free electrons. Because the cathode is strongly negatively charged, it powerfully attracts these positively charged Argon ions.

Step 2: The Collision and Ejection

The attracted Argon ions accelerate toward the cathode and collide with its surface (the target) with significant kinetic energy. This high-energy bombardment is powerful enough to physically knock out, or sputter, atoms from the target material.

Step 3: Journey to the Substrate

These newly ejected atoms of target material travel through the vacuum chamber and land on the substrate (the object being coated), gradually building up a thin, uniform film.

Common Pitfalls and Technical Realities

While the concept is straightforward, the cathode's function presents practical challenges that are critical to manage for successful deposition.

Target Erosion and Uniformity

The magnetic field that traps the plasma is not uniform across the target face. This causes the ions to bombard a specific region more intensely, creating a distinct erosion groove often called a "racetrack." This non-uniform erosion affects the lifespan of the target and the uniformity of the film being deposited.

Unwanted Deposition and Flaking

Sputtered atoms from the cathode can end up on other elements within the vacuum chamber, such as shielding or the anode. Over time, this buildup can flake off and contaminate the substrate, or it can cause changes in the system's electrical properties, leading to process instability or short circuits.

Material and Power Supply Mismatch

The type of target material dictates the type of power supply connected to the cathode. DC (Direct Current) sputtering works well for conductive materials. However, if the target is an electrical insulator, positive charge will build up on its surface, stopping the attraction of ions and halting the process. In this case, an RF (Radio Frequency) power supply must be used to alternate the potential and prevent this charge buildup.

Making the Right Choice for Your Goal

The cathode-target assembly is the primary variable you control to achieve your desired film properties.

- If your primary focus is deposition rate: Success depends on the cathode's magnetic field strength, which dictates how well the plasma is confined near the target surface.

- If your primary focus is film purity: You need a high-purity target material and well-designed chamber shielding to prevent sputtered material from the cathode from contaminating other surfaces and flaking onto your substrate.

- If your primary focus is coating an insulating material (like a ceramic): You must ensure your cathode is connected to an RF power supply, as a DC supply will not work.

Ultimately, mastering the conditions at the cathode is the key to controlling the quality, purity, and properties of your sputtered thin film.

Summary Table:

| Function | Description | Key Consideration |

|---|---|---|

| Negative Electrode | Attracts positive ions from the plasma. | Provides the electrical potential for the process. |

| Source Material Holder | The mounted target is the material to be deposited. | Target material and purity define the final film. |

| Plasma Engine | Magnets trap electrons to create a dense plasma. | Magnetic field design impacts deposition rate and uniformity. |

Ready to Optimize Your Sputtering Process?

The cathode is the core of your deposition system, and its performance directly impacts your results. KINTEK specializes in high-quality lab equipment and consumables, including sputtering targets and systems designed for maximum efficiency and purity.

Whether you need to improve deposition rates, ensure film purity, or select the right power supply for insulating materials, our expertise can help you achieve superior thin films. Contact our experts today to discuss your specific laboratory needs and discover how KINTEK's solutions can enhance your research and production.

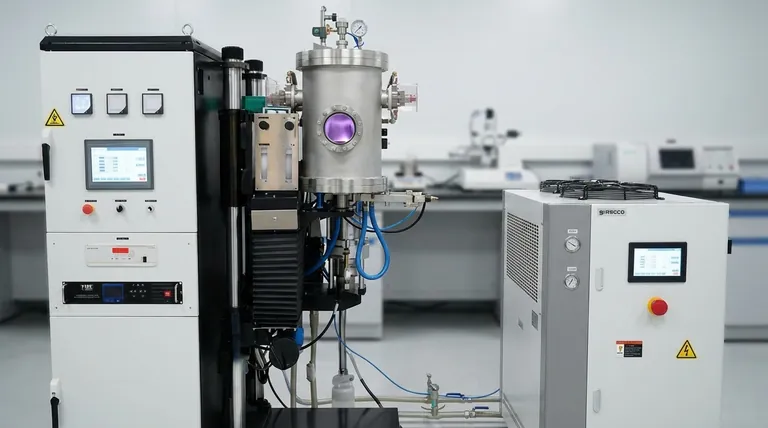

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Three-dimensional electromagnetic sieving instrument

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Evaporation Crucible for Organic Matter

People Also Ask

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the function of a vacuum furnace? Achieve High-Purity, Contamination-Free Thermal Processing

- What is sintering reaction? Transform Powders into Dense Solids Without Melting

- What is the sintering process of powder metallurgy? Transform Powder into Durable Metal Parts