At its core, a channel induction furnace is an electric furnace that operates like a transformer. It uses a primary induction coil wrapped around an iron core to induce a powerful electric current in a closed loop, or "channel," of molten metal. This molten metal acts as the secondary coil, and its electrical resistance generates intense heat that circulates through a larger bath, efficiently melting or holding the metal at a precise temperature.

The defining characteristic of a channel furnace is its use of a specific, contained loop of molten metal as a key part of the electrical circuit. This design makes it highly efficient for holding and superheating large volumes of liquid metal but requires a "heel" of molten metal to start.

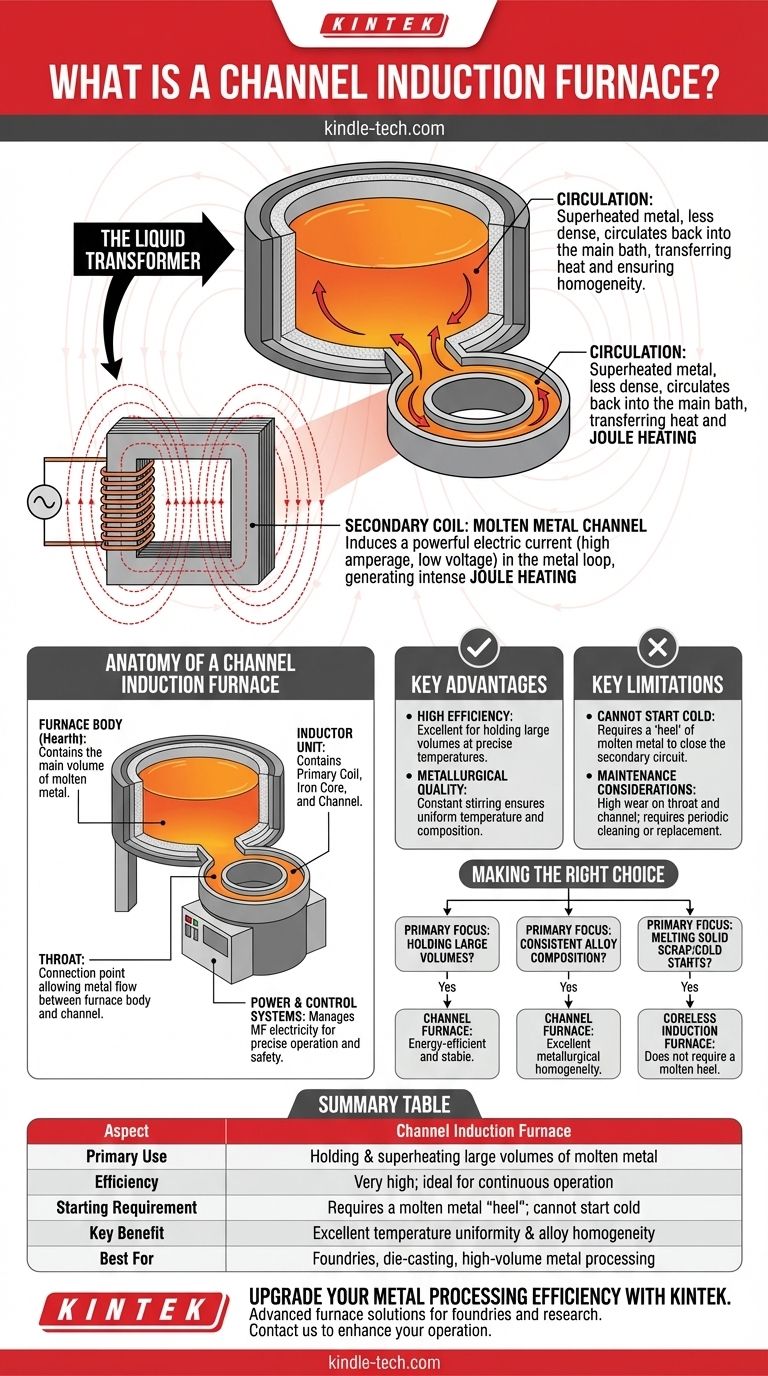

The Core Operating Principle: A Liquid Transformer

The operation of a channel furnace is best understood by visualizing it as a specialized transformer where the secondary winding is a liquid.

The Primary Coil and Iron Core

The heart of the furnace is the inductor unit. This unit contains a primary coil of copper wire wound around a laminated iron core, just like a standard transformer. An alternating current (AC) from a power supply is passed through this coil.

The Molten Metal Channel (The Secondary Coil)

The iron core concentrates the resulting magnetic field, which passes through a specially designed, refractory-lined channel that is part of the furnace structure. This channel is designed to hold a continuous, closed loop of molten metal.

How Heat is Generated

The fluctuating magnetic field induces a very high amperage, low-voltage electric current within the molten metal loop. The metal's natural resistance to the flow of this powerful current generates extreme heat (Joule heating) precisely where it's needed—within the metal itself.

The Role of Circulation

The superheated metal in the narrow channel becomes less dense and is propelled by electromagnetic forces back into the main furnace bath. This process creates a continuous, natural circulation, which efficiently transfers heat to the larger volume of metal and ensures a uniform temperature and homogenous alloy composition.

Anatomy of a Channel Induction Furnace

While designs vary, all channel furnaces share a few critical components that work in concert.

The Furnace Body (Hearth)

This is the main, refractory-lined steel vessel that contains the bulk of the molten metal. Its primary function is to hold the charge safely at high temperatures.

The Inductor Unit

Attached to the bottom or side of the main furnace body is the inductor unit. This is the complete assembly containing the primary coil, the iron core, and the refractory material that forms the channel.

The Throat

The throat is the critical connection point between the main furnace body and the inductor's channel. It allows molten metal to flow freely between the two, completing the secondary circuit and enabling heat transfer through circulation.

Power and Control Systems

A sophisticated power supply provides the necessary medium-frequency electricity. A modern control system manages this power, automatically adjusting voltage and current based on the furnace charge and providing crucial safety protections against over-voltage or over-current events.

Understanding the Trade-offs

No technology is perfect for every application. The unique design of a channel furnace presents clear advantages and distinct limitations.

Key Advantage: High Efficiency

The use of an iron core to tightly couple the magnetic field with the molten metal loop makes channel furnaces exceptionally efficient, both electrically and thermally. They are ideal for holding large amounts of metal at a specific temperature for extended periods with minimal energy loss.

Key Advantage: Metallurgical Quality

The constant, gentle stirring action created by the circulation of metal from the channel ensures excellent melt homogeneity. This leads to a consistent temperature throughout the bath and a uniform chemical composition in the final alloy.

Major Limitation: Cannot Start Cold

The most significant operational constraint is the need for a continuous electrical circuit. A channel furnace cannot start with solid, cold material because this would leave the secondary circuit open. It must be started with a pre-formed solid block or, more commonly, charged with an initial amount (a "heel") of molten metal.

Maintenance Considerations

The throat and channel areas are subjected to extreme heat and metal flow, making them high-wear points. Over time, these areas can become clogged with slag or oxides, requiring periodic, specialized maintenance to clean or replace the inductor.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on the intended metallurgical operation.

- If your primary focus is holding large volumes of metal at a precise temperature: The channel furnace is an exceptionally energy-efficient and stable choice, making it ideal for large foundries or die-casting operations.

- If your primary focus is melting solid scrap or performing frequent cold starts: A coreless induction furnace, which does not require a molten heel, is the superior technology for this task.

- If your primary focus is consistent alloy composition and quality control: The natural stirring action of a channel furnace provides excellent metallurgical homogeneity, making it a strong contender for producing high-quality alloys.

Ultimately, the channel induction furnace is a highly specialized tool engineered for thermal efficiency and stability in continuous, high-volume operations.

Summary Table:

| Aspect | Channel Induction Furnace |

|---|---|

| Primary Use | Holding & superheating large volumes of molten metal |

| Efficiency | Very high; ideal for continuous operation |

| Starting Requirement | Requires a molten metal "heel"; cannot start cold |

| Key Benefit | Excellent temperature uniformity & alloy homogeneity |

| Best For | Foundries, die-casting, high-volume metal processing |

Upgrade your metal processing efficiency with KINTEK's advanced furnace solutions. Whether you're managing a foundry or producing high-quality alloys, our expertise in lab and industrial equipment ensures you get the right technology for your needs. Contact us today to discuss how a channel induction furnace can enhance your operation's performance and consistency.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys