In essence, chemical vapor deposition (CVD) is a scalable industrial process for growing high-quality, large-area sheets of graphene. The method involves heating a gaseous carbon source, known as a precursor, in a chamber with a metal foil, which acts as a catalyst. At high temperatures, the gas decomposes, and the resulting carbon atoms arrange themselves into a single, continuous layer of graphene on the surface of the metal.

The core of the CVD process is a transformation: it turns a simple carbon-based gas into a highly structured, two-dimensional sheet of graphene. This is achieved by using a metal catalyst to "capture" and "organize" carbon atoms from the decomposed gas at very high temperatures.

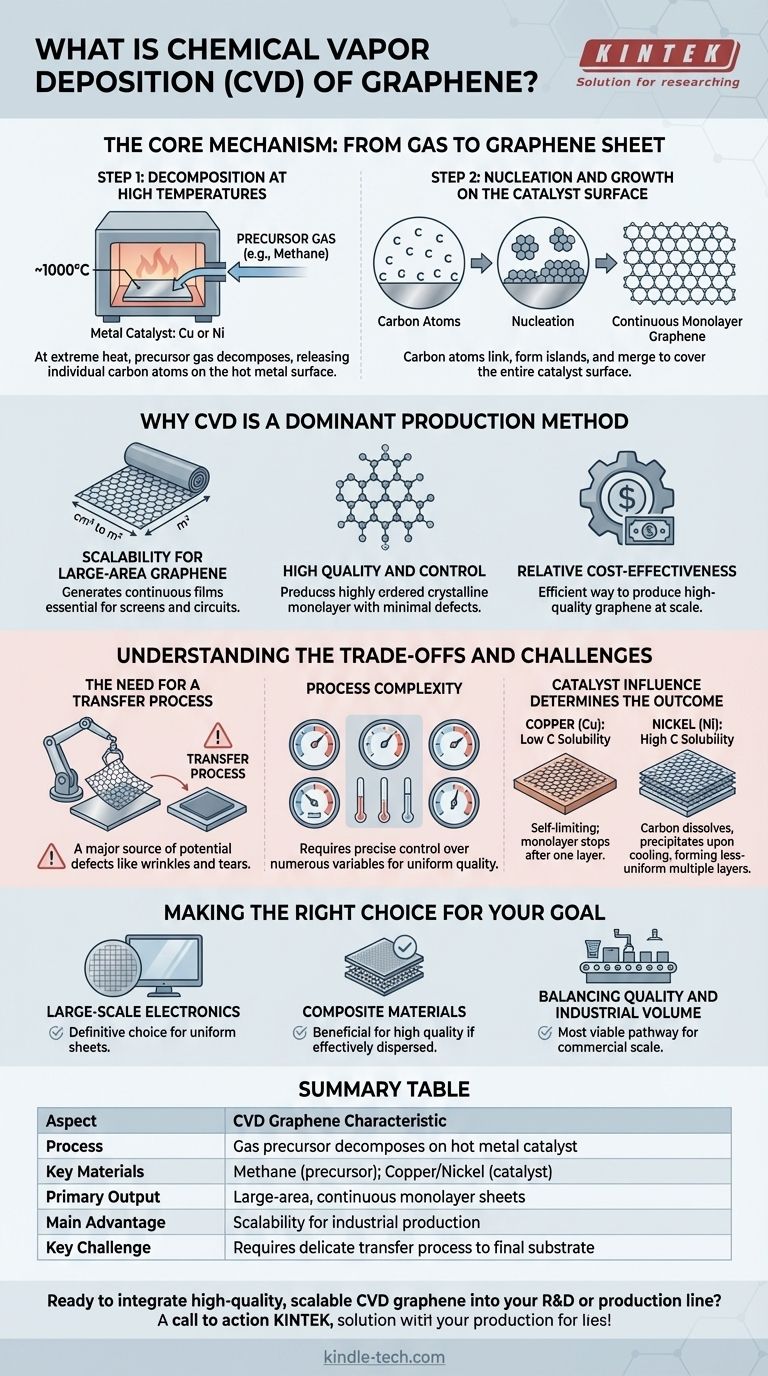

The Core Mechanism: From Gas to Graphene Sheet

The CVD process can be understood as a precise, two-step atomic construction project occurring within a high-temperature reactor.

The Key Ingredients: Precursor and Catalyst

The process requires two primary components: a carbon precursor and a metal catalyst.

The precursor is a carbon-containing material—most often a gas like methane or acetylene—that will be broken down to supply the carbon atoms.

The catalyst is typically a thin foil of metal, with copper (Cu) and nickel (Ni) being the most common choices. Its role is to dramatically lower the energy needed for the reaction to occur.

Step 1: Decomposition at High Temperatures

The metal catalyst is placed inside a vacuum chamber, which is heated to around 1000 °C. The precursor gas is then introduced into the chamber.

At this extreme temperature, the precursor gas molecules become unstable and pyrolyze, or decompose, when they come into contact with the hot metal surface. This breaks the molecules apart, releasing individual carbon atoms.

Step 2: Nucleation and Growth on the Catalyst Surface

Once freed, these carbon atoms diffuse or "skate" across the metal surface. They begin to link together at various points, forming small graphene islands in a process called nucleation.

As more carbon atoms land on the surface, they attach to the edges of these islands, causing them to grow and eventually merge. This continues until a continuous, single atomic layer of graphene covers the entire surface of the catalyst.

Why CVD is a Dominant Production Method

CVD is not just one method among many; it has become the leading technique for producing graphene intended for advanced applications.

Scalability for Large-Area Graphene

Unlike methods that produce tiny flakes, CVD can generate graphene sheets measured in square centimeters or even meters. This ability to create large, continuous films is essential for applications like transparent conductive screens and electronic circuits.

High Quality and Control

The CVD process produces monolayer graphene with a highly ordered crystalline structure and minimal defects. Researchers have fine-tuned the process to control variables like the number of graphene layers with high precision.

Relative Cost-Effectiveness

While requiring sophisticated equipment, CVD is considered a relatively inexpensive and efficient way to produce high-quality graphene at scale compared to more complex laboratory methods like mechanical exfoliation.

Understanding the Trade-offs and Challenges

Despite its advantages, the CVD method is not without its complexities and inherent limitations.

The Need for a Transfer Process

Graphene grown via CVD forms on a metal catalyst, but its final application is almost always on a different substrate, such as silicon or flexible plastic. This requires a delicate transfer process to lift the graphene sheet off the metal and place it on its target material.

This transfer step is a major source of potential defects, such as wrinkles, tears, or contamination, which can compromise the graphene's performance.

Process Complexity

Achieving a perfectly uniform, defect-free monolayer of graphene requires extremely precise control over numerous variables. Factors like temperature, pressure, gas flow rates, and cooling speed all have a significant impact on the final quality.

Catalyst Influence Determines the Outcome

The choice of metal catalyst fundamentally changes the growth mechanism. On copper, which has low carbon solubility, graphene growth is self-limiting and stops after a single layer forms on the surface.

On nickel, which has high carbon solubility, carbon atoms can dissolve into the metal and then precipitate out upon cooling. This can lead to the formation of multiple, less-uniform graphene layers.

Making the Right Choice for Your Goal

Understanding the nature of CVD graphene helps determine its suitability for a specific application.

- If your primary focus is large-scale electronics: CVD is the definitive choice because it is the only mature method for producing the large, uniform graphene sheets required for wafers and displays.

- If your primary focus is creating composite materials: You may not need large sheets, but the high quality of CVD graphene can still be beneficial if you can effectively disperse it after removing it from the catalyst.

- If your primary focus is balancing quality and industrial volume: CVD provides the most viable pathway for manufacturing high-performance graphene at a scale and cost suitable for commercial products.

Ultimately, the chemical vapor deposition process is the critical bridge that takes graphene from a laboratory curiosity to a viable material for real-world technology.

Summary Table:

| Aspect | CVD Graphene Characteristic |

|---|---|

| Process | Gas precursor decomposes on hot metal catalyst |

| Key Materials | Methane (precursor); Copper/Nickel (catalyst) |

| Primary Output | Large-area, continuous monolayer sheets |

| Main Advantage | Scalability for industrial production |

| Key Challenge | Requires delicate transfer process to final substrate |

Ready to integrate high-quality, scalable CVD graphene into your R&D or production line? KINTEK specializes in providing the advanced lab equipment and consumables essential for precise CVD processes. Our expertise supports researchers and industries in developing next-generation electronics, composites, and materials. Contact our experts today to discuss how we can help you achieve your material science goals.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating