Without a doubt, the most common heat treatment process used to increase the hardness of steel is known as hardening, which consists of heating the metal to a specific temperature and then rapidly cooling it in a process called quenching. This is almost always followed by a secondary heat treatment called tempering to reduce brittleness and improve toughness.

The core principle is not just about heating and cooling; it's about using temperature to intentionally manipulate the steel's internal crystal structure, trapping it in a hard but brittle state (quenching) and then carefully refining that structure to achieve a useful balance of hardness and toughness (tempering).

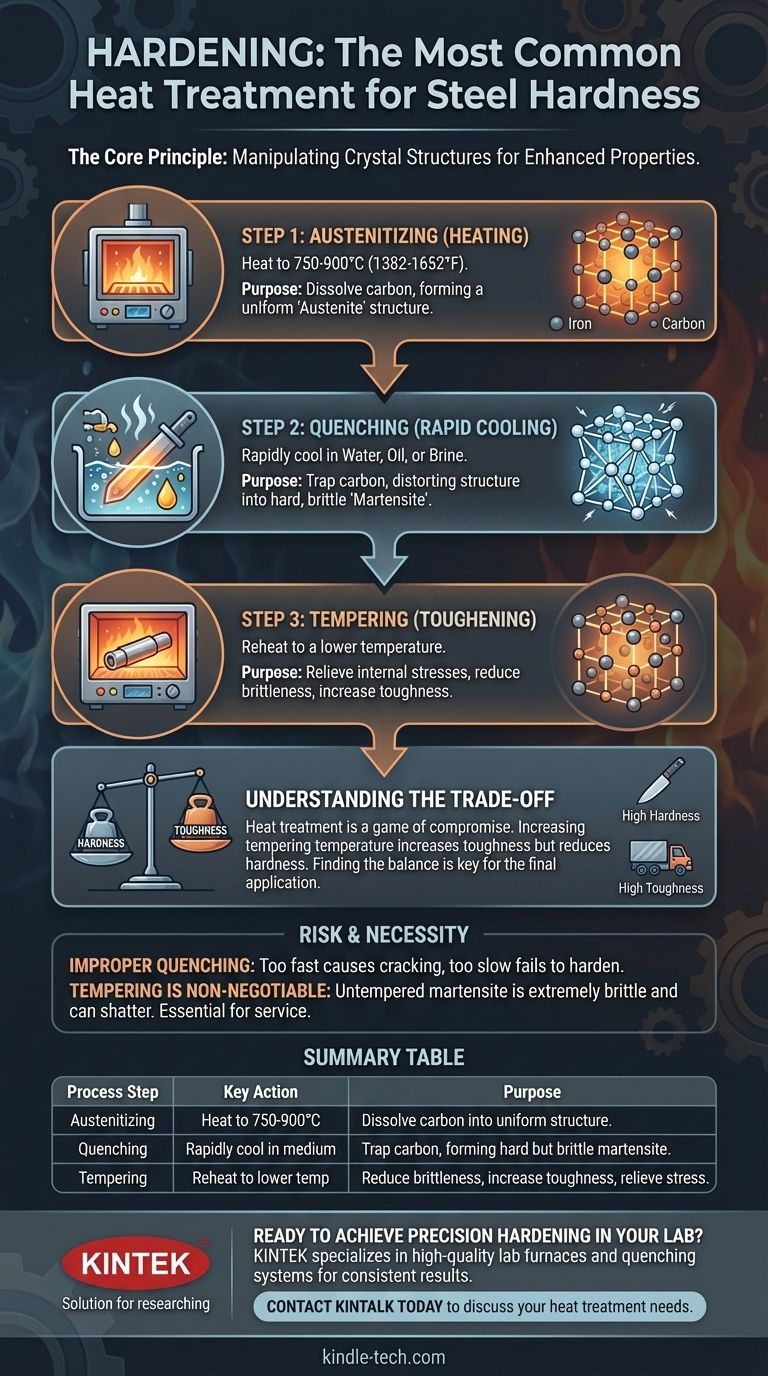

The Core Principle: Manipulating Crystal Structures

To understand hardening, you must first understand that steel is not a static material. At a microscopic level, its iron and carbon atoms arrange themselves into different crystal structures depending on the temperature. Heat treatment is the deliberate control of these structures.

Step 1: Austenitizing (The Heating Phase)

The process begins by heating the steel into the austenitic range, typically between 750-900°C (1382-1652°F). At this temperature, the steel's crystal structure changes into a form called austenite.

Think of austenite as a microscopic sponge. It has a unique ability to dissolve carbon atoms from elsewhere in the steel into its own structure, creating a uniform, carbon-rich solid solution. This step is critical; without it, there is nothing to harden.

Step 2: Quenching (The Rapid Cooling Phase)

Once the carbon is evenly dissolved, the steel is quenched—cooled rapidly by immersing it in a medium like water, oil, or brine.

This sudden drop in temperature doesn't give the carbon atoms time to escape the iron crystal structure as they normally would during slow cooling. Instead, they become trapped, distorting the structure into a new, highly strained, and very hard phase called martensite. The formation of martensite is the primary source of the dramatic increase in hardness.

Step 3: Tempering (The Toughening Phase)

Steel in its freshly quenched, martensitic state is extremely hard but also very brittle, much like glass. For most practical applications, this brittleness makes it unusable, as it would shatter under impact or stress.

To solve this, the hardened part is immediately reheated to a much lower temperature in a process called tempering. This controlled reheating allows some of the trapped carbon to precipitate out, relieving the internal stresses within the martensite. This crucial step reduces hardness slightly but significantly increases the material's toughness (its ability to absorb energy and deform without fracturing).

Understanding the Trade-offs: Hardness vs. Toughness

Heat treatment is not a magic bullet; it is a game of compromise. The properties you gain are directly balanced by the properties you sacrifice.

The Inevitable Compromise

You cannot maximize hardness and toughness simultaneously. The higher the tempering temperature, the more toughness is restored, but the more hardness is lost. The goal is to find the precise balance required for the component's final application. A knife blade needs high hardness for edge retention, while a truck axle needs high toughness to resist shock.

The Risk of Improper Quenching

The quenching process is aggressive and induces immense thermal stress. If not performed correctly, it can lead to severe consequences. Cooling too quickly can cause the part to crack, while cooling too slowly will fail to produce the fully hardened martensitic structure.

Why Tempering is Non-Negotiable

Forgetting or skipping the tempering step is one of the most common mistakes for beginners. Untempered martensite is so brittle that it can crack under its own internal stresses or with the slightest impact. For any component that will see service, tempering is an essential part of the hardening process.

Matching the Process to Your Goal

The "right" heat treatment is entirely dependent on the desired outcome for the final part.

- If your primary focus is maximum hardness and wear resistance (e.g., cutting tools, files): You will use a lower tempering temperature to retain as much of the martensitic hardness as possible.

- If your primary focus is a balance of strength and shock resistance (e.g., axles, bolts, structural components): You will use a higher tempering temperature to sacrifice some hardness in exchange for a significant gain in toughness.

- If you need to harden only the surface of a part (e.g., gears, camshafts): You would look to specialized methods like case hardening or induction hardening, which apply this same principle to only the outer layer of the component.

Ultimately, hardening is the foundational process for transforming a piece of steel from a soft, workable material into a strong, durable, and high-performance component.

Summary Table:

| Process Step | Key Action | Purpose |

|---|---|---|

| Austenitizing | Heat to 750-900°C (1382-1652°F) | Dissolve carbon into a uniform structure for hardening. |

| Quenching | Rapidly cool in water, oil, or brine | Trap carbon, forming a hard but brittle martensite structure. |

| Tempering | Reheat to a lower temperature | Reduce brittleness and increase toughness by relieving internal stresses. |

Ready to Achieve Precision Hardening in Your Lab?

Mastering heat treatment requires reliable and precise equipment. KINTEK specializes in high-quality lab furnaces and quenching systems designed for consistent and repeatable hardening and tempering processes.

Our solutions help metallurgy labs, research institutions, and manufacturing facilities achieve the perfect balance of hardness and toughness in their steel components.

Contact KINTALK today to discuss your specific heat treatment needs and discover how our equipment can enhance your results and efficiency.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation