In environmental chemistry, deposition is the process by which chemical pollutants and other substances are removed from the atmosphere and transferred to the Earth's surface. This includes deposition onto soil, vegetation, lakes, rivers, and oceans. It represents the final stage of a pollutant's journey through the air, directly linking atmospheric contamination to its impact on terrestrial and aquatic ecosystems.

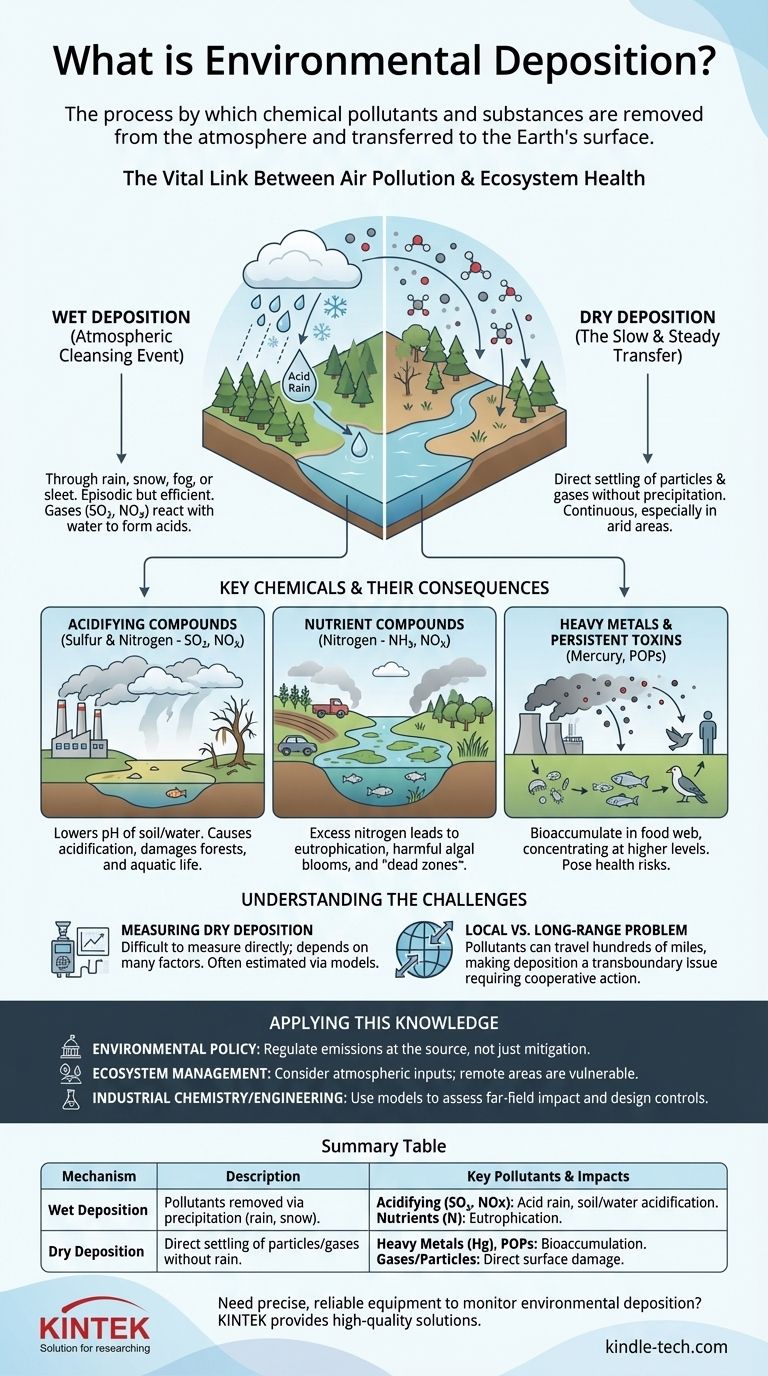

Deposition is the critical bridge between air pollution and its tangible environmental consequences. The core concept to grasp is that it is not a single process, but occurs via two distinct mechanisms—wet deposition (through rain and snow) and dry deposition (the direct settling of particles and gases)—which together determine how, where, and when pollutants damage our environment.

The Two Fundamental Pathways of Deposition

To understand the impact of atmospheric pollutants, we must first distinguish between the two primary ways they reach the ground. The balance between these two pathways depends on the chemical, the climate, and the local geography.

Wet Deposition: The Atmospheric Cleansing Event

Wet deposition occurs when pollutants are incorporated into water droplets in clouds and then fall to the earth as precipitation, such as rain, snow, fog, or sleet.

This process often involves chemical transformation. For example, gases like sulfur dioxide (SO₂) and nitrogen oxides (NOx) react with water, oxygen, and other chemicals in the atmosphere to form acids. These acids then dissolve in cloud water, resulting in the phenomenon known as acid rain.

Wet deposition is highly efficient at "scavenging" or washing pollutants out of the atmosphere. However, it is an episodic process, meaning its impact is concentrated during and immediately after precipitation events.

Dry Deposition: The Slow and Steady Transfer

Dry deposition is the transfer of atmospheric pollutants to a surface in the absence of precipitation. This is a slower, more continuous process than wet deposition.

It happens in two main ways. First, particles (aerosols, dust, soot) slowly settle out of the air due to gravity. Second, gases can be directly absorbed by surfaces, including vegetation, soil, and water bodies.

While less dramatic than a burst of acid rain, dry deposition can be a significant, and sometimes dominant, source of pollution, especially in arid climates or in areas close to emission sources.

Key Chemicals and Their Consequences

Deposition is not a generic process; its environmental impact is defined by the specific chemicals being deposited.

Acidifying Compounds (Sulfur and Nitrogen)

The most well-known culprits are sulfur dioxide (SO₂) and nitrogen oxides (NOx), primarily from burning fossil fuels. Once in the atmosphere, they form sulfuric and nitric acid.

When deposited, these acids lower the pH of soil and water bodies. This acidification can leach essential nutrients from soil, damage forest canopies, and kill fish and other organisms in sensitive lakes and streams.

Nutrient Compounds (Nitrogen)

Nitrogen compounds, including ammonia (NH₃) from agriculture and NOx from combustion, also act as fertilizers when deposited.

While nitrogen is essential for life, excess deposition into aquatic ecosystems causes eutrophication. This over-fertilization triggers harmful algal blooms that, upon dying, deplete the water of oxygen, creating "dead zones" where fish cannot survive.

Heavy Metals and Persistent Toxins

Toxic substances like mercury from coal combustion and persistent organic pollutants (POPs) from industrial processes and pesticides can be transported long distances in the atmosphere.

Their deposition allows them to enter the food web. Because they are not easily broken down, these toxins bioaccumulate, becoming more concentrated at higher trophic levels and posing a health risk to wildlife and humans who consume contaminated fish.

Understanding the Trade-offs and Challenges

Studying and managing deposition is complicated by inherent scientific and logistical challenges. Acknowledging these limitations is crucial for creating effective policy.

The Challenge of Measuring Dry Deposition

Wet deposition is relatively straightforward to measure: you collect precipitation over a specific area and analyze its chemical content.

Dry deposition is notoriously difficult to measure directly. It depends on a complex interplay of wind speed, turbulence, surface characteristics (e.g., a rough forest canopy vs. a smooth lake), and the chemical's properties. Because of this, its contribution is often estimated with computer models rather than measured, introducing a degree of uncertainty.

The Local vs. Long-Range Problem

Pollutants can be deposited within a few miles of their source or be carried by winds for hundreds or even thousands of miles across state and national borders.

This makes deposition a transboundary pollution problem. The acid rain that damages a forest in one country may have originated from emissions in another, creating significant regulatory and diplomatic challenges. The solution cannot be purely local; it requires broad, cooperative action on emissions.

How to Apply This Knowledge

Understanding deposition is key to connecting emissions to environmental outcomes. Your focus will determine which aspect of this process is most critical.

- If your primary focus is environmental policy: Recognize that deposition is a transboundary issue, meaning effective control requires regulating emissions at their source, not just mitigating their effects where they land.

- If your primary focus is ecosystem management: Treat the atmosphere as a direct input to your ecosystem. Sensitive habitats like alpine forests and remote lakes are often impacted by invisible pollutants deposited from hundreds of miles away.

- If your primary focus is industrial chemistry or engineering: Understand that atmospheric transport and deposition models are essential tools for assessing the far-field environmental impact of facility emissions and for designing effective pollution control strategies.

By grasping the mechanisms of deposition, you connect the invisible chemistry of the air to the visible health of the world around us.

Summary Table:

| Mechanism | Description | Key Pollutants & Impacts |

|---|---|---|

| Wet Deposition | Pollutants removed via precipitation (rain, snow). | Acidifying Compounds (SO₂, NOx): Causes acid rain, soil/water acidification. Nutrients (N): Leads to eutrophication. |

| Dry Deposition | Direct settling of particles/gases without rain. | Heavy Metals (e.g., Mercury), POPs: Bioaccumulation in food webs. Gases/Particles: Direct surface damage. |

Need precise, reliable equipment to monitor environmental deposition or analyze pollutant impacts? KINTEK specializes in high-quality lab equipment and consumables for environmental chemistry. From air samplers to analytical instruments, our solutions help you accurately track pollutants and assess ecosystem health. Contact our experts today to find the right tools for your research or monitoring needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What is the process of THC distillate? A Step-by-Step Guide to Pure Potency

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What are the advantages of belt filter press? Achieve High-Volume Dewatering with Low Operational Cost

- What precautions should be taken during evaporation lab? Master High-Vacuum, High-Temperature Safety

- What is the role of a constant temperature shaking incubator in the immobilization of cadmium ions by SRB?

- How can biomass be improved? Strategies for Enhanced Feedstocks and Conversion Technologies

- What are the technical advantages of using Ni-Al or Ti-Cu interlayers? Precision Bonding for Ni-Cr Alloy Foils

- Why must compacted MoS2 powder cylinders undergo in-situ sintering? Ensure Structural Survival in Plasma Reactors