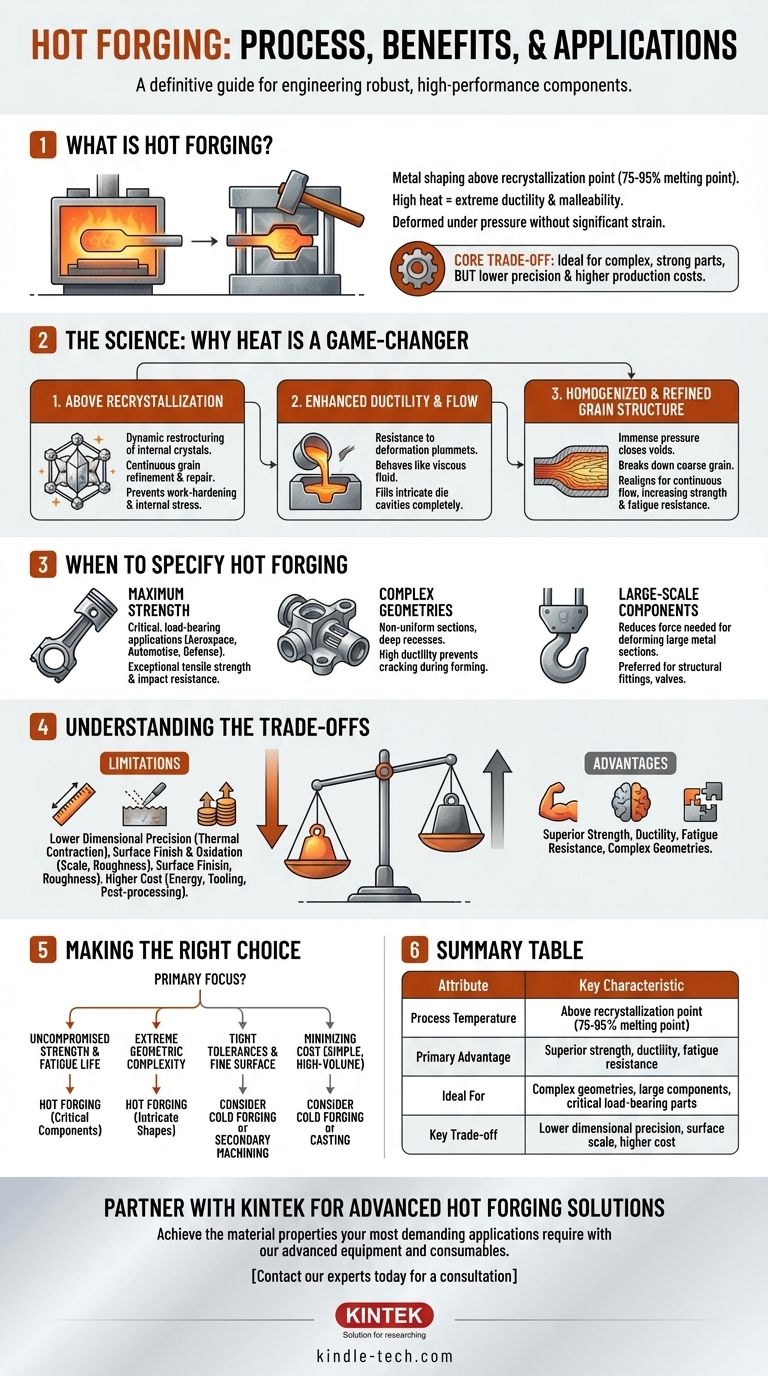

In essence, hot forging is a metal shaping process where the workpiece is heated to a temperature above its recrystallization point, typically ranging from 75% to 95% of its melting point. This extreme heat makes the metal significantly more ductile and malleable, allowing it to be deformed and shaped in a die under high pressure without significant strain.

The core decision to use hot forging hinges on a critical trade-off: it is the ideal process for creating geometrically complex parts with superior strength, but this performance comes at the cost of lower dimensional precision and higher production expenses compared to other methods.

The Science of Hot Forging: Why Heat is a Game-Changer

To understand when to use hot forging, you must first understand its fundamental metallurgical impact. The process is defined by heating metal past a critical threshold, which fundamentally changes its behavior.

Above the Recrystallization Point

Heating a metal above its recrystallization temperature allows for a dynamic restructuring of its internal crystals. This means that as the material is deformed, its grain structure is continuously refined and repaired, preventing the work-hardening and internal stresses that occur during cold forming.

Enhanced Ductility and Flow

At these high temperatures, the metal’s resistance to deformation plummets. It behaves more like a viscous fluid, allowing it to flow and completely fill the intricate cavities of a forging die. This is what enables the creation of highly complex shapes in a single process.

Homogenized and Refined Grain Structure

The immense pressure of the forging process closes any internal voids or porosity present in the raw metal billet. The combination of heat and pressure breaks down the coarse, cast grain structure and realigns it to follow the contour of the part, resulting in a continuous grain flow that dramatically increases strength, ductility, and fatigue resistance.

When to Specify Hot Forging

Hot forging is not a universal solution. It is a specialized process chosen when the performance requirements of the final part justify its specific characteristics.

For Parts Requiring Maximum Strength

This is the primary driver for hot forging. The refined, continuous grain structure yields components with exceptional tensile strength and impact resistance. This makes it indispensable for critical, load-bearing applications in the aerospace, automotive, and defense industries, such as engine crankshafts, connecting rods, and landing gear components.

For Creating Complex Geometries

When a part's design involves non-uniform cross-sections, deep recesses, or intricate features, hot forging is often the only viable manufacturing method. The high ductility of the heated metal ensures it can fill the die completely without cracking or failing.

For Large-Scale Components

Deforming very large metal sections requires an enormous amount of force. Heating the workpiece drastically reduces the force needed, making hot forging the preferred method for producing large components like industrial hooks, large valves, or structural fittings.

Understanding the Trade-offs

Choosing hot forging means accepting a clear set of compromises. An objective assessment requires acknowledging its limitations.

Lower Dimensional Precision

The significant temperature change during the process—from forging heat to room temperature—causes thermal contraction. This makes achieving tight tolerances directly from the forge difficult. Hot forged parts often require secondary machining to meet final dimensional specifications.

Surface Finish and Oxidation

Exposing metal to extreme heat in the presence of oxygen inevitably causes a layer of scale (oxide) to form on the surface. This results in a rougher surface finish compared to cold forming and may require a post-processing step like sandblasting for removal.

The Higher Cost Factor

Hot forging is generally more expensive. Costs are driven by the massive energy consumption required for heating, the reduced lifespan of tooling (dies wear out faster at high temperatures), and the potential need for additional steps like quenching and machining.

Making the Right Choice for Your Application

Ultimately, the decision to use hot forging must be aligned with the end goal of your component.

- If your primary focus is uncompromised strength and fatigue life: Hot forging is the definitive choice for critical components where failure is not an option.

- If your primary focus is extreme geometric complexity: Hot forging provides the material flow needed to produce intricate shapes that other processes cannot achieve.

- If your primary focus is tight tolerances and a fine surface finish: You should consider cold forging or extensive secondary machining after hot forging.

- If your primary focus is minimizing cost for a simple, high-volume part: Hot forging is likely overkill, and a process like cold forging or casting would be more economical.

By understanding this balance between ultimate performance and production realities, you can confidently select the right manufacturing process for your engineering goals.

Summary Table:

| Hot Forging Attribute | Key Characteristic |

|---|---|

| Process Temperature | Above metal's recrystallization point (75-95% of melting point) |

| Primary Advantage | Superior strength, ductility, and fatigue resistance |

| Ideal For | Complex geometries, large components, critical load-bearing parts |

| Key Trade-off | Lower dimensional precision, surface scale, higher cost |

Need a robust, high-performance component?

Hot forging is the definitive choice for parts where failure is not an option. The process delivers exceptional strength and fatigue life by creating a continuous, refined grain structure, making it ideal for critical applications in aerospace, automotive, and heavy industry.

At KINTEK, we specialize in providing the advanced equipment and consumables necessary for precise and reliable hot forging processes. Our solutions help you achieve the material properties your most demanding applications require.

Let's discuss how we can support your project's success. Contact our experts today for a consultation.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the pros and cons of sputtering? Achieve Superior Thin Film Quality & Versatility

- Why is DC sputtering used for metals? Unlock Faster, More Cost-Effective Metal Deposition

- What is bio-oil production and uses? A Guide to Liquid Biomass for Energy & Chemicals

- What is the effect of sputtering pressure? Master Atomic Energy for Superior Thin Films

- What is the recommended storage temperature for human serum? Preserve Sample Integrity for Reliable Results

- Is there a machine to test diamonds? A Guide to Modern Diamond Verification Technology

- What is sputtering in plasma treatment? A Guide to High-Purity Thin Film Deposition

- What is the material of filter press? Why Reinforced Polypropylene is the Industry Standard