At its core, Hot Isostatic Pressing (HIP) is a high-performance manufacturing process that subjects components to both elevated temperature and extremely high, uniform gas pressure. The components are heated in a sealed, high-pressure containment vessel. An inert gas, typically argon, is then used to apply pressure equally from all directions, effectively squeezing out internal defects like porosity and voids to create a fully dense, uniform material.

The true value of HIP is its ability to transform a good component into an exceptional one. By eliminating microscopic internal flaws, the process unlocks the theoretical maximum density, ductility, and fatigue resistance of a material—properties that are often unattainable through casting or additive manufacturing alone.

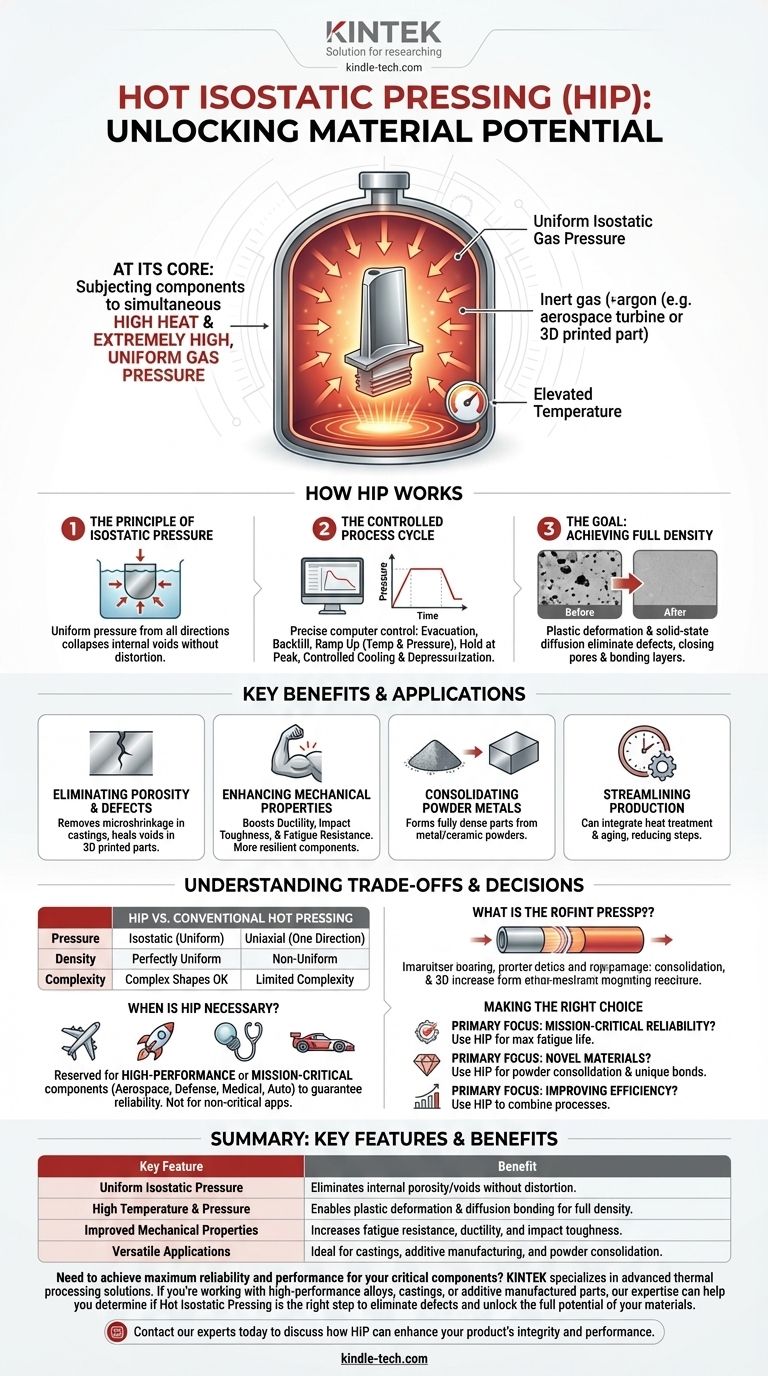

How Hot Isostatic Pressing Fundamentally Works

To understand the benefits of HIP, it's crucial to grasp the principles that make it so effective. The process is more than just applying heat and pressure; it's a precisely controlled metallurgical transformation.

The Principle of Isostatic Pressure

The key is in the name: isostatic. This means the pressure is applied uniformly in all directions. Imagine an object submerged deep in the ocean—the water pressure acts on it equally from every side. HIP replicates this effect with inert gas at high temperatures.

This uniform pressure is critical because it collapses internal voids and pores without distorting the part's overall geometry. Unlike conventional pressing, which applies force in one direction, isostatic pressure ensures consistent densification throughout the entire component.

The Controlled Process Cycle

A typical HIP cycle is managed by sophisticated computer controls to ensure precision and repeatability.

First, parts are loaded into the HIP vessel, which is then sealed. The internal atmosphere is evacuated, and the vessel is backfilled with an inert gas like argon.

Next, the temperature and pressure are ramped up simultaneously according to a programmed schedule specific to the material and part. The component is held at peak temperature and pressure for a set duration, allowing internal voids to close and diffusion bonding to occur at a microscopic level.

Finally, the vessel is cooled and depressurized in a controlled manner, ensuring the part is stable and safe to handle upon removal.

The Goal: Achieving Full Density

The combination of intense heat and pressure enables plastic deformation and solid-state diffusion. The heat softens the material, while the isostatic pressure provides the force to collapse gas-filled or vacuum pores.

This process effectively eliminates microshrinkage in castings and closes the voids between layers in additively manufactured (3D printed) parts. The result is a homogenous, fully dense microstructure.

Key Benefits and Applications

The unique capabilities of HIP make it indispensable in industries where component failure is not an option. Its primary function is to enhance material properties for critical applications.

Eliminating Porosity and Defects

The most common application of HIP is the complete removal of internal porosity. In metal castings, this eliminates microshrinkage, a common source of crack initiation. In 3D printed metal parts, it heals voids and improves layer-to-layer bonding, solving common reliability issues.

Enhancing Mechanical Properties

By creating a fully dense and uniform microstructure, HIP significantly improves a material's mechanical properties. This includes a marked increase in ductility, impact toughness, and fatigue resistance. Parts become more resilient to wear, heat, and abrasion.

Consolidating Powder Metals

HIP can be used to consolidate metal or ceramic powders into a solid, fully dense part. The powder is sealed in a metallic canister shaped like the final component. During the HIP cycle, the canister deforms around the powder, compacting it into a solid billet with uniform properties.

Streamlining Production

For certain alloys, the HIP thermal cycle can be engineered to incorporate heat treatment, solutioning, and aging steps. This consolidation of manufacturing processes can reduce the total number of steps, saving both time and cost in production.

Understanding the Trade-offs

While powerful, HIP is a specialized process that is not universally required. Understanding its context is key to using it effectively.

HIP vs. Conventional Hot Pressing

Conventional hot pressing applies force in a single direction (uniaxially). This is effective for simple shapes but often results in non-uniform density and can limit geometric complexity.

HIP's use of isostatic pressure allows it to produce parts with perfectly uniform density, regardless of shape. While HIP often operates at lower temperatures than forging, its unique pressure application results in superior material consolidation.

When Is HIP Necessary?

HIP is an additional processing step that adds cost and lead time. It is primarily reserved for high-performance or mission-critical components.

Industries like aerospace, defense, medical implants, and high-performance automotive rely on HIP to guarantee the reliability and fatigue life of components like turbine blades, structural airframe parts, and surgical implants. It is generally overkill for non-critical applications.

Limitations and Considerations

The process is batch-based, which can be a bottleneck in high-volume production. The size of the components is also limited by the internal dimensions of the HIP vessel. Finally, the capital investment for HIP equipment is significant, making it a specialized capability.

Making the Right Choice for Your Application

Deciding whether to specify HIP depends entirely on your performance requirements and the cost of failure.

- If your primary focus is mission-critical component reliability: Use HIP to eliminate internal defects in castings or 3D printed parts to achieve maximum fatigue life and structural integrity.

- If your primary focus is creating novel or high-performance materials: Leverage HIP to consolidate metal powders into fully dense parts or to diffusion-bond dissimilar materials for unique properties.

- If your primary focus is improving production efficiency: Investigate if HIP can be used to combine heat treatment and aging cycles for your specific alloy, potentially reducing overall manufacturing steps.

Ultimately, understanding Hot Isostatic Pressing empowers you to specify and create components that meet the highest standards of performance and reliability.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Uniform Isostatic Pressure | Eliminates internal porosity and voids without distorting part geometry. |

| High Temperature & Pressure | Enables plastic deformation and diffusion bonding for a fully dense microstructure. |

| Improved Mechanical Properties | Significantly increases fatigue resistance, ductility, and impact toughness. |

| Versatile Applications | Ideal for castings, additive manufacturing (3D printing), and powder consolidation. |

Need to achieve maximum reliability and performance for your critical components?

KINTEK specializes in advanced thermal processing solutions. If you're working with high-performance alloys, castings, or additive manufactured parts, our expertise can help you determine if Hot Isostatic Pressing is the right step to eliminate defects and unlock the full potential of your materials.

Contact our experts today to discuss how HIP can enhance your product's integrity and performance.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Anti-Cracking Press Mold for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- Why is a heated laboratory hydraulic press necessary for composite laminates? Achieve Void-Free Structural Integrity

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection

- Which features of vacuum hot pressing equipment are utilized by the dual-step vacuum hot press process? Optimize AlMgTi

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process