At its core, hot isostatic pressing (HIP) is a high-pressure thermal treatment used to produce materials with unparalleled integrity. It is primarily used for three main purposes: to eliminate internal porosity in castings and 3D printed parts, to consolidate metal or ceramic powders into a fully dense solid, and to create a powerful metallurgical bond between two or more different materials.

The fundamental goal of hot isostatic pressing is not just to treat a material, but to transform it. By applying uniform high temperature and immense pressure, it removes the internal voids and inconsistencies that are the root cause of mechanical failure, resulting in a virtually perfect material.

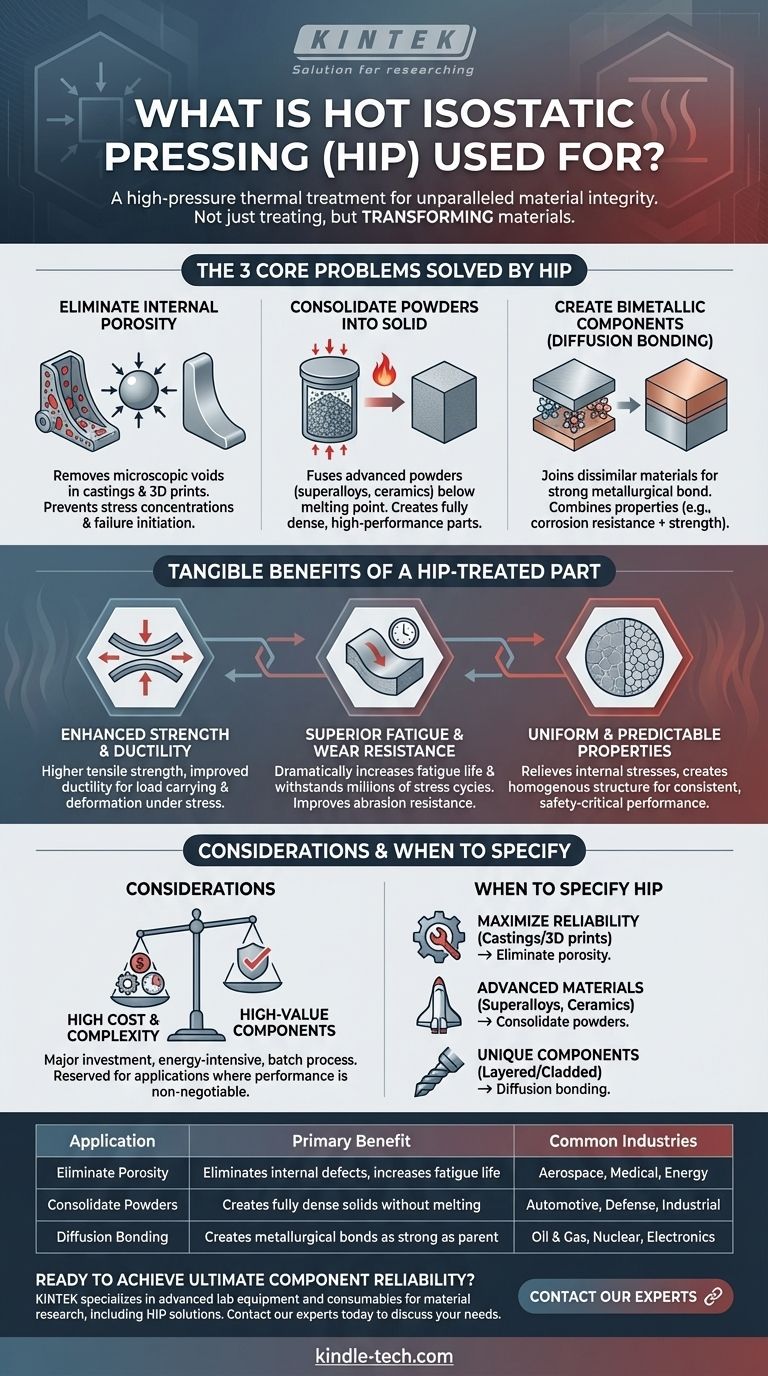

The Core Problems Solved by HIP

Hot isostatic pressing is not a conventional manufacturing step; it is a specialized process deployed to solve critical material challenges that other methods cannot address. It fundamentally re-engineers a material's internal structure.

Eliminating Internal Defects and Porosity

Many manufacturing processes, including metal casting and additive manufacturing (3D printing), can leave behind microscopic internal voids or pores. These tiny empty spaces act as stress concentrators and are the starting points for cracks and component failure.

HIP subjects a part to immense, uniform pressure from all directions. This pressure physically collapses and welds shut these internal voids, creating a fully dense, uniform microstructure and eliminating the root cause of many material failures.

Consolidating Powders into a Solid Form

For advanced materials like superalloys and technical ceramics, melting and casting can be difficult or can degrade their properties. HIP provides a solution by starting with the material in powder form.

The powder is sealed in a canister, which is then placed in the HIP unit. The combination of high heat and pressure forces the individual powder particles to bond and fuse on an atomic level, creating a solid, high-performance component without ever reaching the material's melting point.

Creating Bimetallic Components (Diffusion Bonding)

HIP can be used to join dissimilar materials together with a bond that is as strong as the parent materials themselves. This process, often called cladding or diffusion bonding, is impossible to achieve with traditional welding.

By placing two different materials in intimate contact within the HIP vessel, the process forces atoms from each material to diffuse into the other. This creates a continuous, seamless metallurgical bond, allowing for the creation of components that combine properties like corrosion resistance and high strength.

The Tangible Benefits of a HIP-Treated Part

Solving these core problems results in components with dramatically improved real-world performance, which is why the process is essential in demanding industries like aerospace, energy, and medical implants.

Enhanced Mechanical Strength and Ductility

By removing porosity, HIP creates a component with a greater cross-sectional area to carry loads. This directly translates to higher tensile strength and improved ductility, allowing the material to deform under stress rather than fracturing.

Superior Fatigue and Wear Resistance

Fatigue failure almost always begins at a microscopic defect. By eliminating these initiation sites, HIP dramatically increases a component's fatigue life, allowing it to withstand millions of stress cycles. This also improves resistance to wear and abrasion.

Uniform and Predictable Material Properties

The process relieves internal stresses and creates a homogenous microstructure throughout the part. This uniformity ensures that the material's properties are consistent and predictable, a critical requirement for safety-critical applications.

Understanding the Trade-offs

While the benefits are significant, hot isostatic pressing is not a universal solution. The primary considerations are cost and complexity.

HIP equipment represents a major capital investment, and the process itself is energy-intensive and operates in batches, adding to production time and cost per part. For this reason, its use is typically reserved for high-value components where performance and reliability are non-negotiable and the cost is justified.

When to Specify Hot Isostatic Pressing

Deciding whether to use HIP depends entirely on your performance requirements and the nature of your component.

- If your primary focus is maximizing the reliability of critical castings or 3D printed parts: Use HIP to eliminate internal porosity and ensure the component meets its full design potential.

- If your primary focus is manufacturing with advanced superalloys, composites, or ceramics: Use HIP to consolidate powders into a fully dense, high-performance solid that cannot be made by other means.

- If your primary focus is creating a unique component with layered or cladded materials: Use HIP for diffusion bonding to achieve a perfect, inseparable metallurgical joint.

Ultimately, hot isostatic pressing is the definitive industrial process for achieving ultimate material integrity when failure is not an option.

Summary Table:

| Application | Primary Benefit | Common Industries |

|---|---|---|

| Eliminate Porosity in Castings/3D Prints | Eliminates internal defects, increases fatigue life | Aerospace, Medical, Energy |

| Consolidate Metal/Ceramic Powders | Creates fully dense solids without melting | Automotive, Defense, Industrial |

| Diffusion Bonding of Dissimilar Materials | Creates metallurgical bonds as strong as parent materials | Oil & Gas, Nuclear, Electronics |

Ready to eliminate material defects and achieve ultimate component reliability?

KINTEK specializes in advanced lab equipment and consumables for material research and development, including solutions for evaluating and implementing Hot Isostatic Pressing. Our expertise helps laboratories and manufacturers in the aerospace, medical, and energy sectors ensure their materials meet the highest standards of performance and safety.

Contact our experts today via our Contact Form to discuss how we can support your quest for unparalleled material integrity.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the core functions of a vacuum hot press sintering furnace? Achieve High-Density & Metallurgical Bonding

- Why is a high vacuum system essential for Ti-22Al-25Nb hot pressing? Protect Your Alloys from Oxidation

- What is the function of axial pressure in hot pressing Al-4Cu alloys? Achieve Peak Densification and Strength

- How does a vacuum hot-press furnace facilitate the densification of diamond/copper composites? Achieve 98.8% Density

- Why are low-carbon steel or pure tantalum canisters used in HIP? Optimize Your Tungsten Powder Consolidation Today

- Is spark a plasma sintering? Discover the Truth About SPS and Its Advantages

- What processing conditions does a vacuum hot press furnace provide? Optimize GNPs-Cu/Ti6Al4V Fabrication

- Why is a 30Pa vacuum necessary for C-SiC-B4C hot pressing? Ensure Material Purity and Density