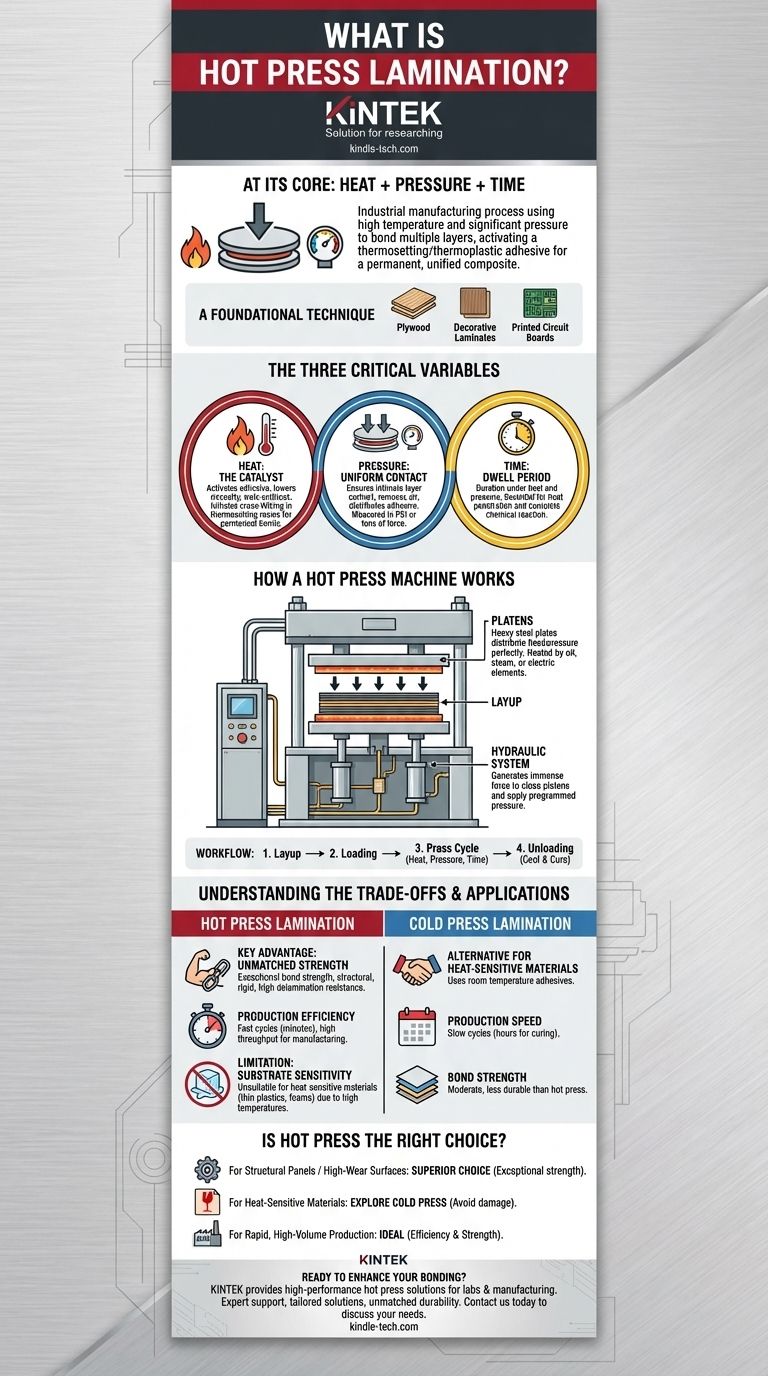

At its core, hot press lamination is an industrial manufacturing process that uses a combination of high temperature and significant pressure to bond multiple layers of material together. This process activates a thermosetting or thermoplastic adhesive, creating a permanent, unified composite material that is often stronger and more stable than its individual components. It is the foundational technique behind common products like plywood, decorative laminates for furniture, and multi-layer printed circuit boards.

The crucial insight is that hot press lamination isn't simply about gluing materials together. It is a controlled process that uses heat and pressure to initiate a chemical or physical transformation, resulting in a bond that is fundamentally integrated into the final product's structure.

The Core Components of the Process

To truly understand hot press lamination, you must see it as a balance of three critical variables: heat, pressure, and time. Each plays a distinct and irreplaceable role in achieving a successful bond.

The Role of Heat

Heat is the catalyst in the lamination process. Its primary function is to activate the adhesive, lowering its viscosity so it can flow and "wet" the surfaces of the substrates completely.

For thermosetting resins (like those used in plywood or high-pressure laminates), heat initiates a chemical reaction called cross-linking. This reaction creates a permanent, irreversible bond that is highly resistant to heat and chemicals once cured.

The Function of Pressure

Pressure ensures intimate and uniform contact between every layer in the stack, or "layup." This is typically applied by large, flat plates called platens and is often measured in pounds per square inch (PSI) or tons of force.

This immense pressure forces out any trapped air, distributes the molten adhesive evenly, and ensures the substrates conform to one another, maximizing the surface area available for bonding.

The Importance of Time

Known as dwell time or press time, this is the duration for which the materials are held under the specified heat and pressure.

This period must be long enough for the heat to penetrate all layers of the material and for the adhesive's chemical reaction to complete. Too little time results in a weak, incomplete bond, while too much time can degrade the materials or the adhesive itself.

How a Hot Press Machine Works

A hot press is a deceptively simple yet powerful piece of industrial machinery designed to deliver heat and pressure with high precision.

The Platens

These are the heavy, flat steel plates that make direct contact with the materials being laminated. They are engineered to distribute heat and pressure perfectly evenly across their entire surface. Platens are typically heated using circulating hot oil, steam, or embedded electrical heating elements.

The Hydraulic System

The immense force required for lamination is generated by a hydraulic system. This system uses fluid pressure to drive one or more large cylinders, which close the platens and apply the programmed amount of pressure onto the material stack.

The Typical Workflow

The process is straightforward and cyclical:

- Layup: Workers stack the layers of substrate material and adhesive sheets or coatings.

- Loading: The complete stack is loaded between the open platens of the press.

- Press Cycle: The press closes, and the programmed heat and pressure are applied for the specified dwell time.

- Unloading: The press opens, and the newly laminated panel is removed to cool and fully cure.

Understanding the Trade-offs

Hot press lamination is a powerful technique, but it is not the universal solution for all bonding applications. Understanding its advantages and limitations is key to making an informed decision.

Key Advantage: Unmatched Bond Strength

The primary benefit is exceptional bond strength and durability. The combination of heat and pressure creates a monolithic bond that is often structural, rigid, and highly resistant to delamination.

Key Advantage: Production Efficiency

For high-volume manufacturing, the process is relatively fast. Press cycles are measured in minutes, allowing for a high throughput of finished panels.

Limitation: Substrate Sensitivity

The high temperatures involved make this process unsuitable for heat-sensitive materials. Substrates like thin plastics, vinyl, or certain foams would warp, melt, or be otherwise damaged by the heat.

Limitation: The Alternative of Cold Pressing

For heat-sensitive applications, cold press lamination is the alternative. It uses adhesives that cure at room temperature over a much longer period (often hours). While effective, the resulting bond is typically not as strong or durable as a hot-pressed one.

Is Hot Press Lamination the Right Choice?

Your decision to use hot press lamination should be driven entirely by the performance requirements of your final product and the nature of your materials.

- If your primary focus is creating structural panels or high-wear surfaces (like countertops or flooring): Hot press lamination is the superior choice due to its exceptional bond strength and durability.

- If your primary focus is bonding heat-sensitive materials (like certain plastics, foams, or pre-printed graphics): You must explore cold press lamination to avoid damaging your substrates.

- If your primary focus is rapid, high-volume production of durable, rigid goods: The efficiency and strength offered by hot press lamination are ideal for industrial-scale manufacturing.

By understanding the fundamental interplay of heat, pressure, and time, you can confidently determine if this process aligns with your material and product goals.

Summary Table:

| Aspect | Hot Press Lamination | Cold Press Lamination |

|---|---|---|

| Bond Strength | Exceptional, structural, and durable | Moderate, less durable |

| Heat Applied | High temperature required | Room temperature |

| Suitable Materials | Heat-resistant substrates (wood, composites) | Heat-sensitive materials (plastics, foams) |

| Production Speed | Fast (minutes per cycle) | Slow (hours for curing) |

Ready to enhance your material bonding process with professional-grade equipment?

At KINTEK, we specialize in providing high-performance hot press machines and expert solutions for laboratories and manufacturing facilities. Whether you're producing durable laminates, structural panels, or advanced composites, our equipment ensures precise control over heat, pressure, and time for flawless results.

Why choose KINTEK for your lab equipment needs?

- Tailored Solutions: We help you select the right press for your specific materials and production goals.

- Unmatched Durability: Our machines are built for industrial-scale efficiency and long-term reliability.

- Expert Support: From installation to maintenance, our team is here to ensure your success.

Contact us today to discuss how our hot press solutions can strengthen your production capabilities. Get in touch via our contact form for a personalized consultation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

People Also Ask

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What are the advantages of using a hot press over a cold press for LiMOCl4 composite cathodes? Boost Battery Efficiency

- How do laboratory hydraulic presses and hot pressing affect MEA preparation? Optimize Your Fuel Cell Efficiency

- What is a 3D sublimation heat press? Unlock Full-Wrap Printing on Curved Objects

- What role does a laboratory hot press play in shielding materials? Optimize Polyaniline/Wollastonite Composite Density

- What is the core function of a laboratory heated hydraulic press in CSP? Revolutionize Low-Temp Ceramic Sintering

- Why is precise pressure control in precision hot presses critical for TlBr crystals? Enhance Your Semiconductor Quality

- What products are made from hot forging? Discover High-Strength Components for Critical Applications