Hydraulic forging is a manufacturing process that uses a hydraulic press to apply a slow, controlled, and immense compressive force to shape metal. Unlike hammer forging, which uses rapid impacts, a hydraulic press squeezes the workpiece, allowing the force to penetrate deep into the material for a more uniform deformation.

The core principle of hydraulic forging is not speed, but power and control. By applying sustained pressure, it deforms the entire volume of a metal workpiece, ensuring a consistent internal structure that is essential for large, high-strength components.

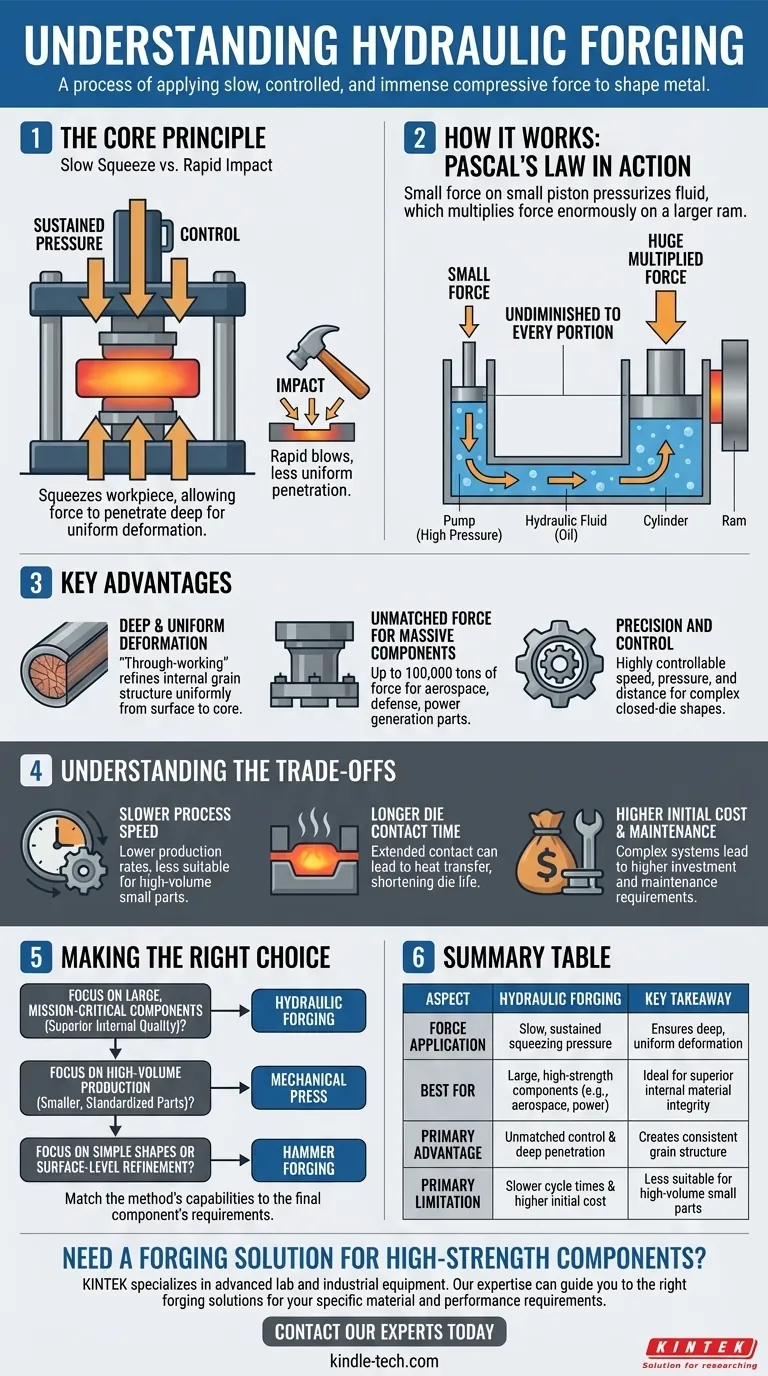

The Core Principle: How Hydraulic Forging Works

Hydraulic forging leverages fundamental fluid dynamics to generate extraordinary force. The process is defined by its method of force application, which differs significantly from impact-based forging.

Pascal's Law in Action

The entire system operates on Pascal's Law, a principle of fluid mechanics. It states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In a hydraulic press, a small force is applied to a small piston, pressurizing a liquid like oil. This pressure is then transmitted through the fluid to a much larger piston, or ram, which multiplies the initial force enormously.

The Role of the Hydraulic Cylinder

The main components are a pump, hydraulic fluid (oil), and a cylinder containing the ram. The pump supplies high-pressure liquid, often stored in an accumulator for rapid release when needed.

This pressurized fluid drives the ram downward with a constant, controllable force. Once the pressing action is complete, the pressure is released, and the ram retracts.

Sustained Pressure, Not Impact

The defining characteristic of hydraulic forging is its squeezing action. The force is applied at a relatively low and constant velocity.

This is fundamentally different from a forging hammer, which strikes the workpiece with high velocity and transfers energy through impact. The sustained pressure of a hydraulic press ensures the deformation occurs throughout the material's cross-section.

Key Advantages of the Hydraulic Method

The unique characteristics of hydraulic forging make it the preferred method for specific, demanding applications where material integrity is paramount.

Deep and Uniform Deformation

Because the force is applied slowly, it has time to penetrate the entire workpiece. This "through-working" refines the metal's internal grain structure uniformly, eliminating defects and creating consistent material properties from the surface to the core.

Unmatched Force for Massive Components

Hydraulic presses can generate staggering amounts of force, with some open-die presses reaching 100,000 tons. This power is necessary for forging extremely large ingots and billets into components for the aerospace, defense, power generation, and heavy industrial sectors.

Precision and Control

The movement of the hydraulic ram is highly controllable in terms of speed, pressure, and distance. This precision makes it ideal for complex shapes and for closed-die forging, where the metal must be forced to completely fill an intricate mold.

Understanding the Trade-offs

No single method is perfect for every application. The strengths of hydraulic forging are accompanied by specific limitations that must be considered.

Slower Process Speed

The deliberate, controlled squeezing action is inherently slower than the rapid blows of a hammer or a mechanical press. This results in lower production rates, making it less suitable for high-volume manufacturing of smaller parts.

Longer Die Contact Time

Because the press moves slowly, the hot workpiece remains in contact with the dies for a longer duration. This extended contact can lead to significant heat transfer from the workpiece to the dies, which can shorten die life and require careful management of the workpiece's temperature.

Higher Initial Cost and Maintenance

Hydraulic systems are complex, involving high-pressure pumps, accumulators, valves, and seals. This complexity leads to a higher initial investment and more demanding maintenance requirements compared to simpler mechanical presses.

Making the Right Choice for Your Goal

Selecting the correct forging process requires matching the method's capabilities to the final component's requirements.

- If your primary focus is on large, mission-critical components with superior internal quality: Hydraulic forging is the definitive choice for its deep, uniform material deformation.

- If your primary focus is on high-volume production of smaller, standardized parts: A faster mechanical press is likely the more cost-effective solution.

- If your primary focus is on simple shapes or surface-level grain refinement: Traditional hammer forging may be a more efficient and economical option.

Ultimately, understanding the trade-offs between force, control, and speed empowers you to select the process that ensures both manufacturing efficiency and final part integrity.

Summary Table:

| Aspect | Hydraulic Forging | Key Takeaway |

|---|---|---|

| Force Application | Slow, sustained squeezing pressure | Ensures deep, uniform deformation throughout the material |

| Best For | Large, high-strength components (e.g., aerospace, power generation) | Ideal for applications requiring superior internal material integrity |

| Primary Advantage | Unmatched control and deep penetration of force | Creates consistent grain structure from surface to core |

| Primary Limitation | Slower cycle times and higher initial cost | Less suitable for high-volume production of small parts |

Need a Forging Solution for High-Strength Components?

Hydraulic forging is the definitive process for creating large, mission-critical parts with superior internal quality. If your projects in aerospace, defense, or heavy industry demand the deep, uniform material properties that only sustained hydraulic pressure can provide, KINTEK is here to help.

KINTEFLOW specializes in advanced lab and industrial equipment. Our expertise can guide you to the right forging solutions for your specific material and performance requirements.

Contact our experts today to discuss how we can support your manufacturing goals with precision equipment and consumables.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Anti-Cracking Press Mold for Lab Use

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance