In essence, isostatic pressing is a powder compaction method that uses uniform, hydrostatic pressure to create a solid object. Unlike traditional methods that press from one or two directions, this technique places powder inside a flexible mold and applies pressure equally from all sides, typically using a fluid medium.

The critical advantage of isostatic pressing is its ability to bypass the limitations of conventional pressing. By applying pressure equally in all directions, it produces components with exceptionally uniform density and strength, even in complex shapes.

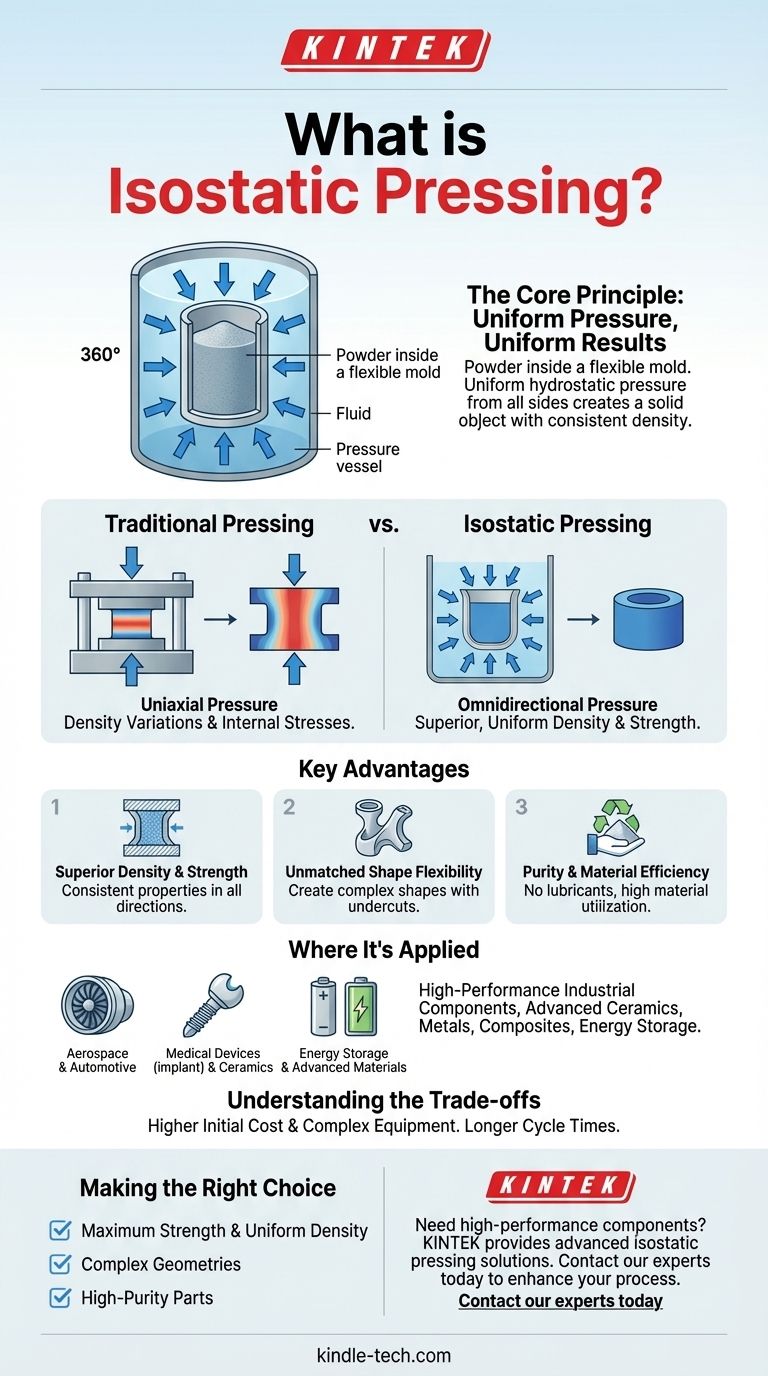

The Core Principle: Uniform Pressure, Uniform Results

Isostatic pressing fundamentally changes how compaction force is applied to a material. This distinction is the source of all its primary benefits.

How It Works

The process involves enclosing a powder within a sealed, flexible mold made of rubber, plastic, or a similar elastomer. This entire assembly is then subjected to high hydrostatic pressure.

The pressure is transmitted through the flexible mold wall, compacting the powder inside equally from every possible direction.

The Key Difference from Traditional Pressing

Traditional uniaxial pressing uses a rigid die and applies force from one direction. This can create density variations and internal stresses within the part, as friction with the die walls impedes uniform powder flow.

Isostatic pressing eliminates this issue entirely. With no rigid die walls to cause friction and with pressure being applied uniformly, the resulting part achieves a much higher and more consistent density.

Key Advantages of the Isostatic Method

The unique approach of isostatic pressing leads to several significant manufacturing advantages, making it the preferred choice for demanding applications.

Superior Density and Strength

Because the compressive forces are perfectly balanced, the final component has uniform density throughout its structure. This uniformity translates directly to consistent, predictable strength in all directions, without the weak points that can be introduced by other methods.

Unmatched Shape Flexibility

The use of a flexible, elastomeric mold removes many of the geometric constraints imposed by rigid dies. This allows for the creation of more complex shapes, including parts with undercuts or varying cross-sections, that would be impossible to produce with uniaxial pressing.

Purity and Material Efficiency

This process compacts powders without the need for lubricants, which are often required in die pressing to reduce friction. This prevents contamination and ensures higher purity of the final material.

Furthermore, it is a highly efficient process for expensive or difficult-to-compact materials, ensuring maximum material utilization.

Understanding the Trade-offs

While highly effective, isostatic pressing is not a universal solution. The equipment required is more complex and often represents a higher capital investment than simple mechanical presses.

Cycle times can also be longer, making it less suitable for certain high-volume, low-cost applications where the ultimate material properties are not the primary concern. The flexible tooling may also have a different lifespan and cost profile compared to hardened steel dies.

Where Isostatic Pressing Is Applied

This technique is crucial in industries where component performance and reliability are non-negotiable.

High-Performance Industrial Components

Isostatic pressing is used to manufacture advanced ceramics and metal parts for the aerospace, automotive, and oil & gas industries. It is also vital for producing medical devices, electrical connectors, and even high-performance ferrites.

Advanced Materials and Technologies

The method is applied to consolidate a wide range of materials, including metals, composites, plastics, and carbon. It is also used in creating components for energy storage, such as lithium-ion batteries and fuel cells, and for processing sensitive materials like pharmaceuticals, nuclear fuel, and even explosives.

Making the Right Choice for Your Goal

Selecting the correct compaction method depends entirely on the requirements of the final component.

- If your primary focus is maximum component strength and uniform density: Isostatic pressing is the superior choice, as it eliminates the internal defects and density gradients common in other methods.

- If your primary focus is creating complex geometries: The flexible tooling of isostatic pressing provides design freedom that rigid dies cannot match.

- If your primary focus is high-purity parts from expensive materials: The lubricant-free nature and high material utilization of this process make it the ideal solution.

Ultimately, isostatic pressing empowers engineers to create components whose material integrity and geometric complexity were previously unachievable.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Powder is enclosed in a flexible mold and subjected to uniform pressure from all sides via a fluid. |

| Primary Advantage | Produces parts with exceptionally uniform density and strength, even in complex shapes. |

| Key Applications | Aerospace components, medical devices, advanced ceramics, lithium-ion batteries, and nuclear fuel. |

| Ideal For | Applications requiring maximum material performance, complex geometries, and high purity. |

Need to manufacture high-performance components with uniform density and complex shapes?

KINTEK specializes in providing advanced isostatic pressing solutions and lab equipment for industries where material integrity is critical. Our expertise helps you achieve superior part quality, maximize material utilization, and push the boundaries of design complexity.

Contact our experts today to discuss how our isostatic pressing technology can enhance your manufacturing process and product performance.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment