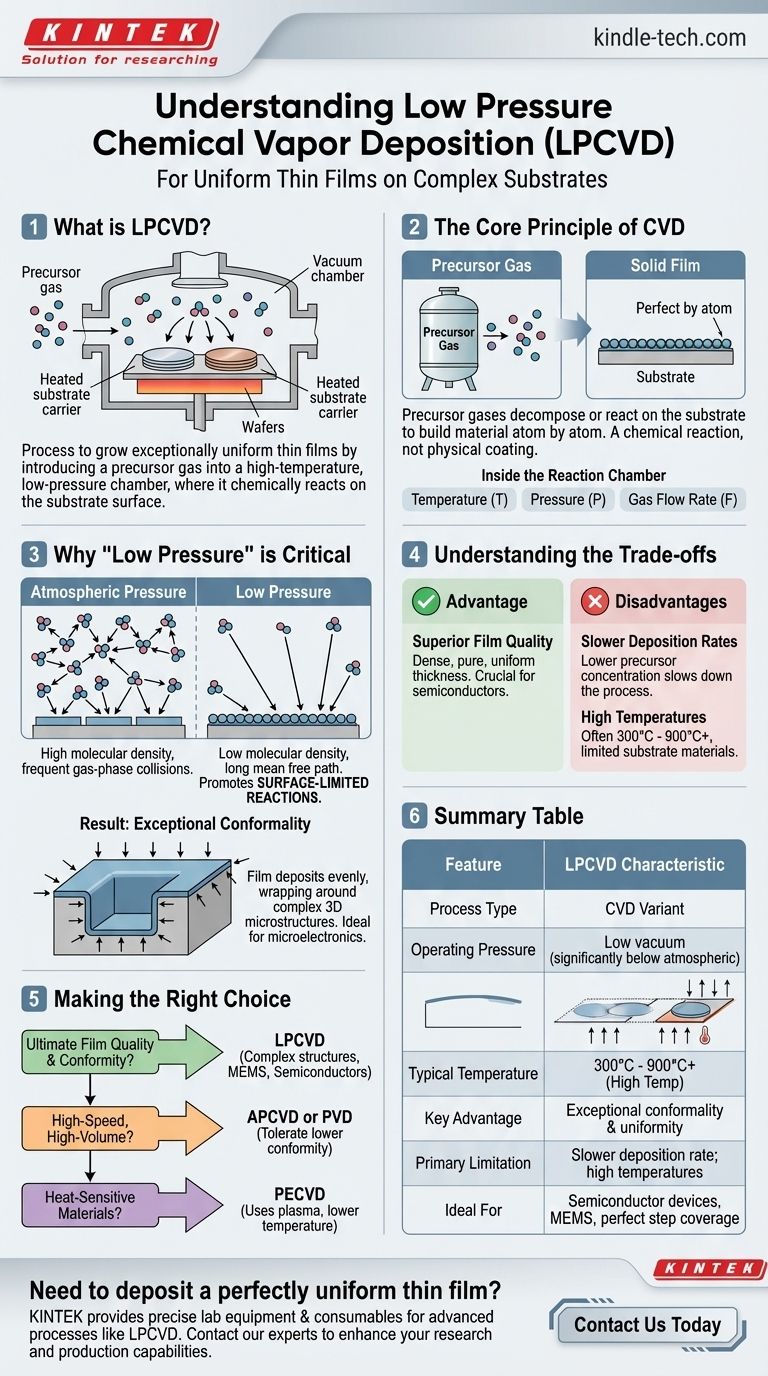

At its core, Low Pressure Chemical Vapor Deposition (LPCVD) is a process used to grow exceptionally uniform thin films on a solid surface, known as a substrate. It accomplishes this by introducing a precursor gas into a high-temperature, low-pressure chamber, where the gas chemically reacts on the substrate’s surface to form the desired solid material.

The central advantage of LPCVD is not simply that it operates in a vacuum, but that this low-pressure environment fundamentally changes how the film forms. It forces the chemical reaction to occur almost exclusively on the target surface, resulting in coatings of unparalleled uniformity and conformity, even over complex, non-flat topographies.

The Fundamentals of Chemical Vapor Deposition (CVD)

To understand LPCVD, we must first understand the foundational process of Chemical Vapor Deposition (CVD).

The Core Principle: Precursor Gas to Solid Film

CVD is a process where a substrate (like a silicon wafer or a cutting tool) is exposed to one or more volatile precursor gases.

These gases decompose or react on the substrate's surface, leaving behind a thin film of solid material. It is a process of building a material atom by atom from a chemical reaction.

Inside the Reaction Chamber

This transformation happens inside a reaction chamber under tightly controlled conditions.

Key parameters like temperature, pressure, and gas flow rate are precisely managed to dictate the final properties of the deposited film, such as its thickness, composition, and crystal structure.

A Chemical Reaction, Not a Physical Coating

Unlike Physical Vapor Deposition (PVD), which is like spray-painting with atoms, CVD creates the film through a chemical change at the surface. This distinction is critical, as it allows CVD to coat intricate and hidden surfaces that PVD's "line-of-sight" methods cannot reach.

Why "Low Pressure" is the Critical Factor

The "Low Pressure" in LPCVD is the specific engineering choice that unlocks its most powerful advantages.

Defining "Low Pressure"

LPCVD operates in a vacuum, at pressures hundreds or thousands of times lower than our normal atmosphere. This dramatically reduces the number of gas molecules present in the chamber at any given moment.

The Impact on Gas Behavior

With fewer molecules, the precursor gas particles can travel much farther before colliding with each other. This is known as a long mean free path.

This means the molecules are far more likely to collide with the heated substrate than with each other in the gas phase.

Promoting Surface-Limited Reactions

Because the reactions happen predominantly on the substrate surface rather than in the gas, the process is considered surface-reaction limited.

The film's growth rate is determined by the reaction speed on the surface, not by how fast the gas can be supplied. This is the secret to LPCVD's precision.

The Result: Exceptional Conformality

This surface-limited mechanism is what gives LPCVD its signature benefit: exceptional conformality and uniformity.

The film deposits evenly across all surfaces it can reach, wrapping perfectly around complex 3D microstructures. This makes it a cornerstone technology in fabricating modern microelectronics, where features are incredibly small and complex.

Understanding the Trade-offs of LPCVD

While powerful, LPCVD is not the universal solution for all deposition needs. Its specific operating conditions create a distinct set of advantages and disadvantages.

Advantage: Superior Film Quality

LPCVD produces films that are incredibly dense, pure, and uniform in thickness. This is crucial for applications in semiconductors and optics where even minor imperfections can cause device failure.

Disadvantage: Slower Deposition Rates

A direct consequence of the low pressure is a lower concentration of precursor gas. This inherently slows down the deposition rate compared to processes run at atmospheric pressure (APCVD).

Requirement: High Temperatures

LPCVD is a thermally driven process, often requiring temperatures between 300°C and 900°C or higher to initiate the necessary chemical reactions. This high heat budget means LPCVD cannot be used on substrates that would melt or be damaged at these temperatures, such as many plastics.

Making the Right Choice for Your Application

Selecting a deposition technology requires matching the process capabilities to your project's primary goal.

- If your primary focus is ultimate film quality and conformity: LPCVD is the definitive choice for coating complex microstructures, as seen in advanced semiconductor and MEMS device fabrication.

- If your primary focus is high-speed, high-volume coating: Processes like Atmospheric Pressure CVD (APCVD) or PVD may be more economical choices, provided you can tolerate lower film conformity.

- If your primary focus is coating heat-sensitive materials: A process like Plasma-Enhanced CVD (PECVD), which uses plasma instead of high heat to drive the reaction, is the necessary alternative.

Ultimately, choosing LPCVD is a strategic decision to prioritize film perfection and uniformity over deposition speed.

Summary Table:

| Feature | LPCVD Characteristic |

|---|---|

| Process Type | Chemical Vapor Deposition (CVD) variant |

| Operating Pressure | Low vacuum (significantly below atmospheric) |

| Typical Temperature | 300°C - 900°C+ (High Temperature) |

| Key Advantage | Exceptional conformality and uniformity on complex 3D structures |

| Primary Limitation | Slower deposition rate compared to APCVD; high temperatures required |

| Ideal For | Semiconductor devices, MEMS, applications requiring perfect step coverage |

Need to deposit a perfectly uniform thin film on a complex substrate? KINTEK specializes in providing the precise lab equipment and consumables needed for advanced processes like LPCVD. Our expertise helps laboratories achieve superior film quality and conformity for semiconductor and MEMS fabrication. Contact our experts today to discuss how we can support your specific deposition requirements and enhance your research and production capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- Is CVD better than HPHT? A Guide to Choosing the Right Lab-Grown Diamond

- What role does a resistance heating furnace play in CVD tantalum coating? Master Thermal Precision in CVD Systems

- What are the advantages of the HFCVD method for preparing diamond films? Faster Growth and Industrial Efficiency

- What are the potential applications of graphene? Unlocking Next-Gen Electronics, Energy, and Materials

- What are the applications of CVD method? From Microchips to Lab-Grown Diamonds

- What are the advantages of vapor deposition? Achieve Unmatched Thin-Film Precision & Performance

- What are the deposition stages and growth patterns in ALCVD? Master Precision Thin-Film Morphology

- Why is a constant temperature water bath used for precursor storage in CVD? Achieve Stable Nanocrystalline SiC Deposition