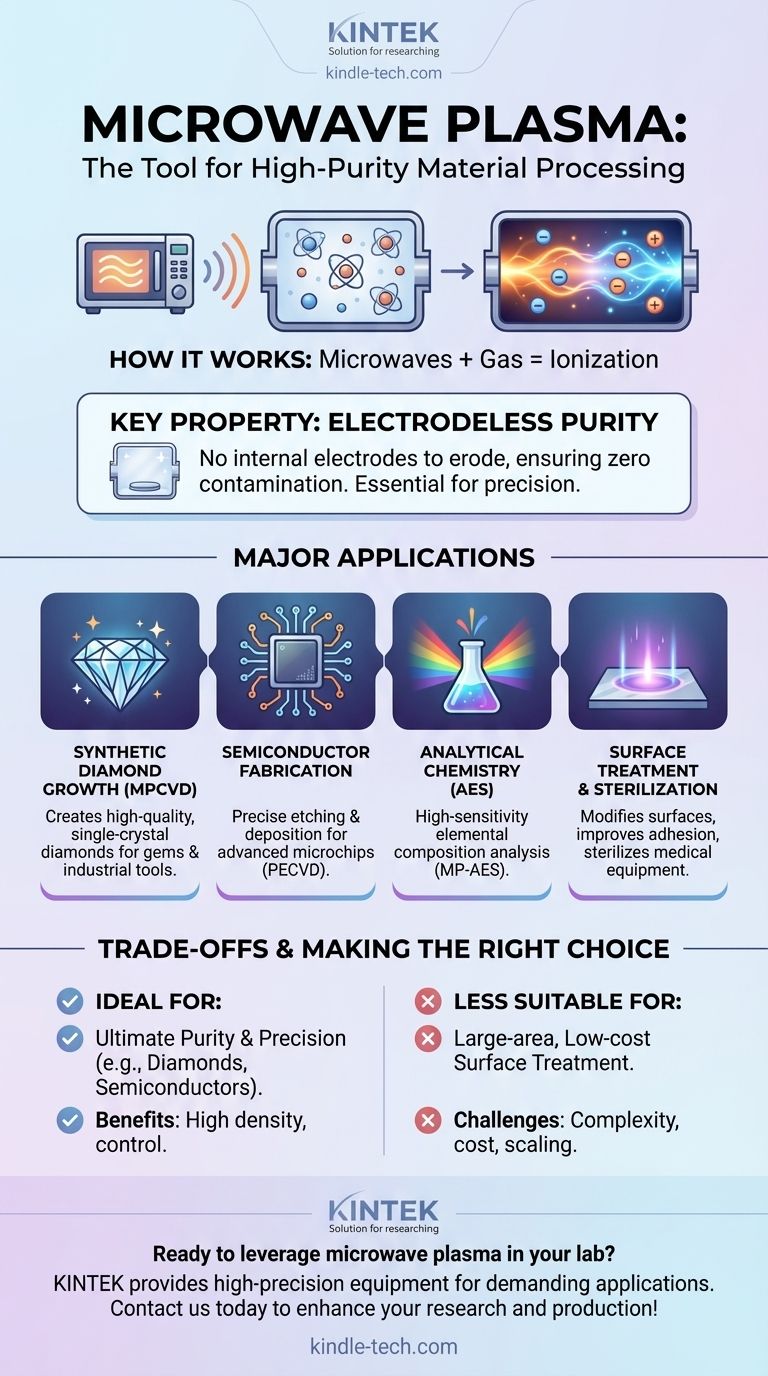

In short, microwave plasma is primarily used for high-purity material processing. Its most significant applications are in growing synthetic diamonds, fabricating advanced semiconductor chips, and performing highly sensitive chemical analysis. The technology's ability to create a dense, highly reactive environment without electrodes—which can be a major source of contamination—makes it the ideal tool for processes where precision and purity are non-negotiable.

The core value of microwave plasma lies in its unique ability to generate a clean and highly concentrated plasma. This makes it the superior choice for high-tech applications that cannot tolerate the contamination or lack of control inherent in other plasma generation methods.

What Makes Microwave Plasma a Unique Tool?

To understand its applications, you must first understand why microwave plasma is different from other plasma generation techniques. It's not just about creating a glowing gas; it's about the quality and characteristics of that gas.

How It Works: Microwaves and Gas

The process is fundamentally simple. A powerful microwave generator, operating at a specific frequency (often 2.45 GHz, the same as a kitchen microwave), directs energy through a waveguide into a sealed chamber containing a low-pressure gas.

This focused microwave energy agitates free electrons within the gas. These electrons oscillate rapidly, colliding with neutral gas atoms and knocking more electrons loose. This chain reaction, called ionization, rapidly transforms the gas into a plasma—a highly energized state of matter consisting of ions, electrons, and reactive neutral particles.

Key Property: Unmatched Purity

The most critical advantage of microwave plasma is that it is electrodeless.

Other common methods, like Direct Current (DC) or Radio Frequency (RF) plasma, often require electrodes to be placed inside the process chamber. Over time, these electrodes can erode or "sputter," releasing metallic particles that contaminate the process and the final product.

Because microwave energy is coupled into the chamber from the outside, there are no internal parts to degrade. This makes it essential for applications like semiconductor manufacturing, where a single microscopic particle can ruin a multi-million dollar batch of microchips.

Key Property: High Density and Efficiency

Microwave plasma systems are highly efficient at transferring energy to the gas, resulting in a high-density plasma.

This means there is a very high concentration of ions and reactive species in a given volume. For industrial processes, higher density translates directly to faster processing speeds, whether that's depositing a thin film, etching a silicon wafer, or growing a diamond crystal.

Where is Microwave Plasma Deployed?

The unique properties of purity and density make microwave plasma the go-to solution in several advanced industries.

Synthetic Diamond Growth (MPCVD)

This is arguably the technology's most prominent application. In a process called Microwave Plasma Chemical Vapor Deposition (MPCVD), a gas mixture like methane is introduced into a hydrogen plasma.

The plasma efficiently breaks down the methane molecules into carbon radicals. These radicals then deposit onto a small diamond seed crystal, meticulously building up a high-quality, single-crystal diamond layer by layer. This method is used to create everything from industrial-grade diamonds for cutting tools and optics to flawless, gem-quality diamonds for jewelry.

Semiconductor Fabrication

In the microelectronics industry, microwave plasma is used for two critical steps: etching and deposition.

For etching, the reactive species in the plasma are used to precisely remove material from a silicon wafer, carving out the intricate circuit patterns of a modern processor. For deposition, it's used to add ultra-thin layers of insulating or conductive materials with exceptional uniformity and purity, a process known as Plasma-Enhanced Chemical Vapor Deposition (PECVD).

Analytical Chemistry (AES)

In a technique called Microwave Plasma-Atomic Emission Spectrometry (MP-AES), a small sample is introduced into the plasma. The intense energy atomizes the sample and excites its atoms, causing them to emit light at unique wavelengths.

By analyzing this light, scientists can determine the precise elemental composition of the sample with incredible sensitivity. Because it can run on nitrogen extracted from the air instead of expensive gases like argon, it's also a more cost-effective analytical tool.

Surface Treatment and Sterilization

The reactive plasma can be used to modify the surface of a material, a process known as surface activation. This can improve paint adhesion, alter a material's wettability, or harden its surface.

Furthermore, the same reactive species can effectively destroy microbes, making microwave plasma a valuable tool for sterilizing heat-sensitive medical equipment without the damaging effects of high temperatures.

Understanding the Trade-offs

Despite its advantages, microwave plasma is not a universal solution. It comes with specific limitations that make other methods more suitable for certain tasks.

Complexity and Cost

Microwave plasma systems are technically complex. They require a microwave generator, waveguides, an impedance matching system, and a carefully designed plasma chamber. This makes them significantly more expensive to build and maintain than simpler DC or some RF plasma systems.

Scaling for Large Areas

Creating a perfectly uniform, high-density plasma over a very large area is an engineering challenge. While excellent for processing silicon wafers or growing individual diamonds, it can be less practical for applications that require treating massive, continuous surfaces, like coating large rolls of plastic film. Other technologies are often better suited for those large-scale tasks.

Making the Right Choice for Your Goal

Selecting a plasma technology depends entirely on the requirements of the application.

- If your primary focus is ultimate purity and precision (like single-crystal diamond or advanced semiconductors): Microwave plasma is the superior choice due to its electrodeless nature and high-density output.

- If your primary focus is cost-effective surface treatment over a very large area: Other technologies like atmospheric pressure plasma or large-area RF systems are likely a better fit.

- If your primary focus is sensitive and low-cost elemental analysis: MP-AES offers a powerful and economical alternative to traditional analytical techniques.

Ultimately, microwave plasma excels in demanding applications where control, density, and unparalleled purity justify its complexity and cost.

Summary Table:

| Application | Key Benefit | Common Use Case |

|---|---|---|

| Synthetic Diamond Growth (MPCVD) | Electrodeless purity | Gem-quality & industrial diamonds |

| Semiconductor Fabrication | Contamination-free processing | Etching & deposition of microchips |

| Chemical Analysis (MP-AES) | High sensitivity & cost-efficiency | Elemental composition analysis |

| Surface Treatment & Sterilization | Effective surface modification | Medical equipment sterilization |

Ready to leverage the power of microwave plasma in your lab?

KINTEK specializes in providing high-precision lab equipment and consumables for demanding applications like semiconductor fabrication, diamond synthesis, and advanced material processing. Our expertise ensures you get the right tools for achieving unparalleled purity and efficiency in your work.

Contact us today to discuss how our solutions can enhance your research and production processes!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition