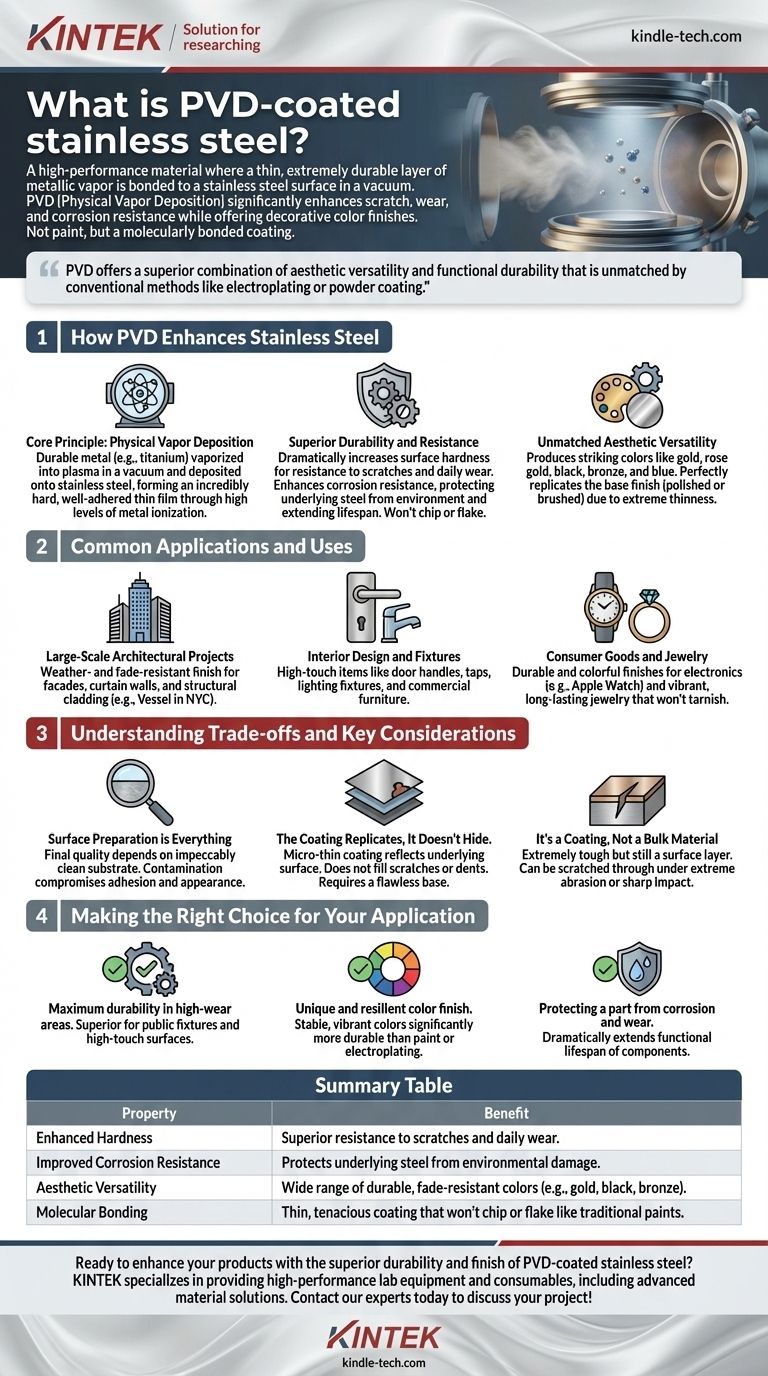

In short, PVD-coated stainless steel is a high-performance material where a thin, extremely durable layer of metallic vapor is bonded to a stainless steel surface in a vacuum. This process, known as Physical Vapor Deposition (PVD), significantly enhances the steel's resistance to scratches, wear, and corrosion while also allowing for a wide range of decorative color finishes.

PVD is not simply a layer of paint; it is a molecularly bonded coating that fundamentally improves the base stainless steel. It offers a superior combination of aesthetic versatility and functional durability that is unmatched by conventional methods like electroplating or powder coating.

How the PVD Process Enhances Stainless Steel

The value of PVD coating lies in how it fundamentally alters the surface of stainless steel, adding properties the base metal alone does not possess.

The Core Principle: Physical Vapor Deposition

Physical Vapor Deposition is an advanced vacuum coating process. A solid material, often a durable metal like titanium, is vaporized into a plasma of atoms or molecules.

This vapor is then deposited onto the stainless steel part, forming a thin but incredibly hard and well-adhered film on the surface. The high levels of metal ionization ensure the coating bonds directly and tenaciously to the steel.

Superior Durability and Resistance

The primary functional benefit of PVD is a dramatic increase in surface hardness. This makes the stainless steel far more resistant to scratches and daily wear.

This process also enhances corrosion resistance, protecting the underlying steel from environmental conditions and maintaining its luster over a much longer lifespan. Its durability is far superior to traditional coatings, which can chip or flake off.

Unmatched Aesthetic Versatility

PVD coatings can produce striking and consistent colors such as gold, rose gold, black, bronze, and blue.

Because the coating is extremely thin, it perfectly replicates the finish of the base material. A polished steel part will have a polished PVD finish, while a brushed part will have a brushed PVD finish, allowing for precise design control.

Common Applications and Uses

PVD-coated stainless steel is specified where both high performance and visual appeal are critical.

Large-Scale Architectural Projects

For exterior applications, PVD provides a weather-resistant and fade-resistant finish. It is used for building facades, curtain walls, and structural cladding, as seen on iconic structures like the Vessel in New York City.

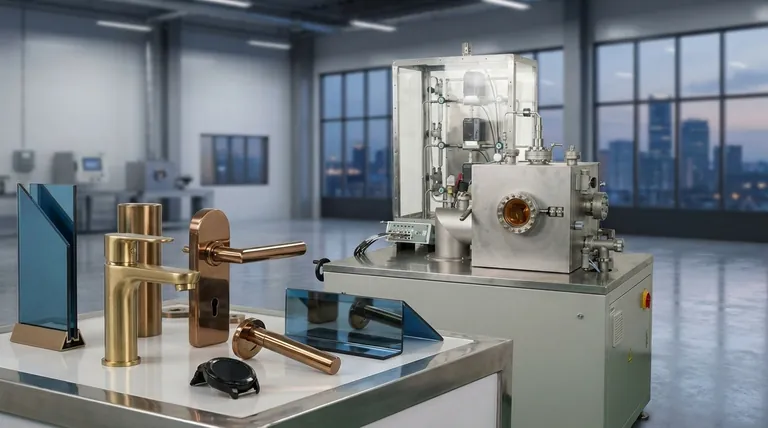

Interior Design and Fixtures

In smaller-scale uses, PVD is found on high-touch items that need to resist wear while looking pristine. This includes door handles, taps, lighting fixtures, and commercial furniture.

Consumer Goods and Jewelry

The technology is also used for consumer electronics, providing the durable and colorful finishes on products like the Apple Watch and iPhone. In jewelry, it creates vibrant, long-lasting colors that won't tarnish or wear away easily.

Understanding the Trade-offs and Key Considerations

While highly effective, the PVD process is not without its critical requirements and limitations. Understanding them is key to a successful outcome.

Surface Preparation is Everything

The final quality of the PVD coating is entirely dependent on the quality of the substrate. The stainless steel part must be impeccably clean before entering the vacuum chamber.

Any contamination, oils, or imperfections on the surface will compromise the coating's adhesion and final appearance.

The Coating Replicates, It Doesn't Hide

PVD is a micro-thin coating. It will not fill in or hide existing scratches, dents, or surface imperfections in the base stainless steel.

The final finish is a direct reflection of the underlying surface. For a flawless result, you must start with a flawless part.

It's a Coating, Not a Bulk Material

Although extremely tough, a PVD coating is still a surface layer. Under extreme abrasion or a sharp impact, it is possible to scratch through the coating and expose the silver-colored stainless steel beneath.

Making the Right Choice for Your Application

Use these guidelines to determine if PVD-coated stainless steel is the correct choice for your project.

- If your primary focus is maximum durability in high-wear areas: PVD is the superior choice for public fixtures, door hardware, and other high-touch surfaces.

- If your primary focus is a unique and resilient color finish: PVD provides stable, vibrant colors like black, gold, or bronze that are significantly more durable than paint or electroplating.

- If your primary focus is protecting a part from corrosion and wear: The enhanced hardness and resistance of a PVD coating will dramatically extend the functional lifespan of a stainless steel component.

Ultimately, choosing PVD is an investment in long-term performance and a premium, lasting finish.

Summary Table:

| Property | Benefit |

|---|---|

| Enhanced Hardness | Superior resistance to scratches and daily wear. |

| Improved Corrosion Resistance | Protects the underlying steel from environmental damage. |

| Aesthetic Versatility | Wide range of durable, fade-resistant colors (e.g., gold, black, bronze). |

| Molecular Bonding | Thin, tenacious coating that won't chip or flake like traditional paints. |

Ready to enhance your products with the superior durability and finish of PVD-coated stainless steel? KINTEK specializes in providing high-performance lab equipment and consumables, including advanced material solutions for demanding applications. Our expertise ensures you get the right materials for longevity and aesthetic appeal. Contact our experts today to discuss how we can support your project's success!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films