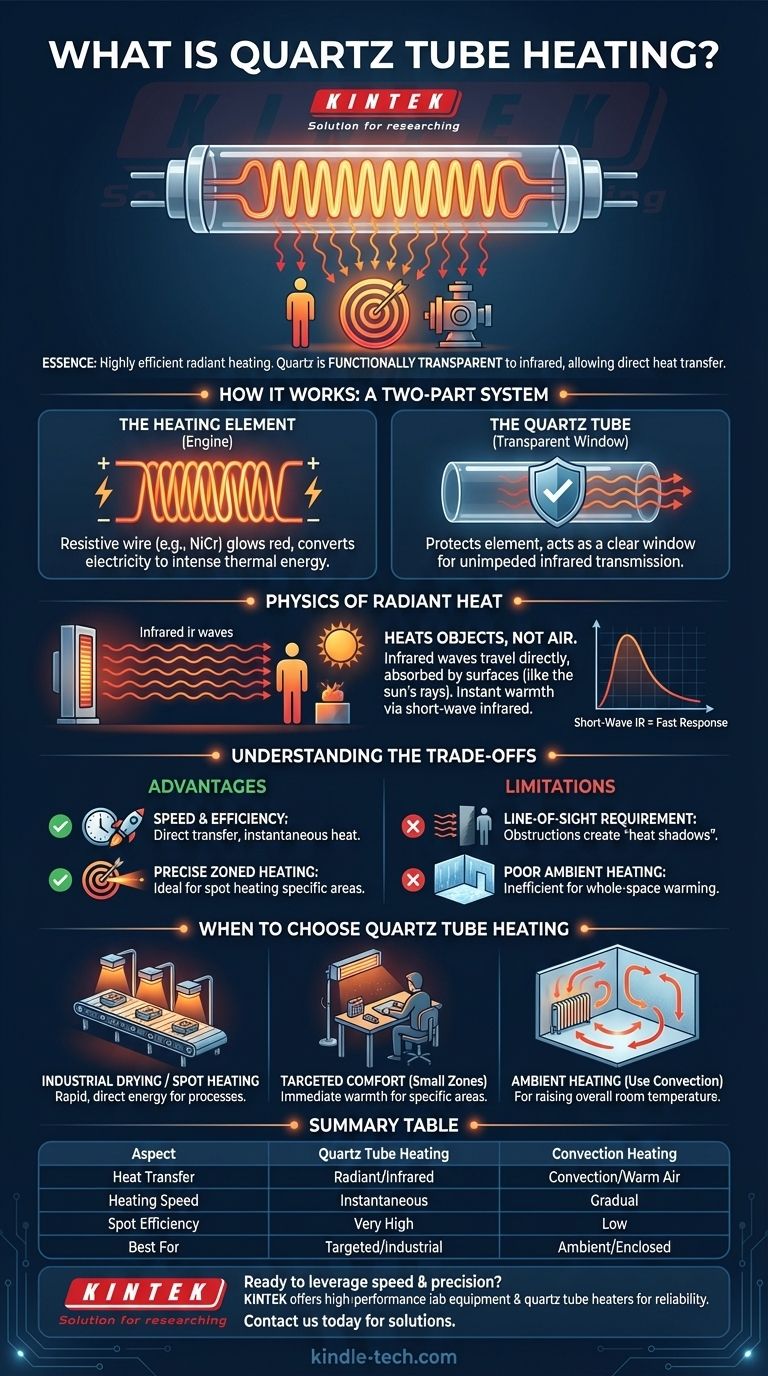

In essence, quartz tube heating is a highly efficient form of radiant heating. This technology uses a coiled wire heating element encased within a quartz tube. The element generates intense heat, which is emitted as infrared radiation that passes directly through the quartz to heat objects and people, rather than wasting energy by heating the surrounding air.

The defining principle of quartz heating is not that the quartz itself gets hot, but that it is functionally transparent to infrared radiation. This unique property allows the energy from the internal element to pass through with minimal loss, delivering heat directly and instantly to a target.

How Quartz Heaters Work: A Two-Part System

To understand this technology, it's best to view it as a system with two critical components working together: the element that creates the heat and the tube that directs it.

The Heating Element: The Engine of Heat

The actual source of heat in a quartz heater is a resistive wire, often made of a nickel-chromium alloy. When electricity passes through this coiled wire, its resistance causes it to become extremely hot, glowing red or orange. This process converts electrical energy into thermal energy.

The Quartz Tube: The Transparent Window

This hot element is enclosed within a tube made of quartz. The role of the quartz is crucial: it does not block the infrared energy. Instead, it acts like a clear window, allowing the infrared waves to pass through it almost entirely unimpeded. This protects the delicate heating element from the environment while ensuring maximum energy transfer.

The Physics of Radiant Heat Transfer

The efficiency of quartz heating comes from its method of heat transfer. Unlike other heaters, it doesn't primarily rely on warming the air.

Heating Objects, Not Air

Quartz heaters emit radiant heat in the form of infrared waves. These waves travel in straight lines and only convert to heat when they are absorbed by a surface, such as a person, a piece of furniture, or a part on an assembly line.

This is fundamentally different from convection heaters, which warm the air and rely on air circulation to distribute warmth. The principle is similar to how the sun warms your face on a cold day—the air may be frigid, but you can feel the direct energy from the sun's rays.

Short-Wave Infrared for Fast Response

The energy emitted by quartz heaters is typically in the short to medium-wave infrared spectrum. Shorter wavelengths are more energetic and can penetrate materials more quickly, resulting in very rapid heating. This is why quartz heaters provide a sensation of warmth almost instantly after being switched on.

Understanding the Trade-offs

While highly effective, quartz heating is not a universal solution. Its advantages are tied to specific use cases, and it has clear limitations.

Advantage: Speed and Efficiency

Because quartz heaters transfer energy directly to the target, they are exceptionally fast. Almost no energy is wasted heating the volume of air between the heater and the object, making them highly efficient for specific tasks.

Advantage: Precise, Zoned Heating

The directional nature of infrared waves allows you to aim the heat precisely where it is needed. This makes it ideal for spot heating a workstation, a patio seating area, or a specific part in an industrial process without heating the entire facility.

Limitation: Line-of-Sight Requirement

Radiant heat travels like light. Any object that physically blocks the path between the heater and the target will create a "heat shadow." The area behind the obstruction will remain unheated.

Limitation: Poor for Whole-Space Ambient Heating

While excellent for targeted zones, quartz heaters are generally inefficient for raising the overall ambient temperature of a large, enclosed, or poorly insulated space. A convection heater is often a better tool for that job.

When to Choose Quartz Tube Heating

Selecting the right heating technology depends entirely on your specific application and goals.

- If your primary focus is rapid spot heating or industrial drying: Quartz is an excellent choice due to its direct, fast-acting, and controllable infrared energy.

- If your primary focus is providing comfort to a person in a small, targeted zone: Quartz provides immediate warmth to a workbench or outdoor seating area without needing to heat the entire surrounding air mass.

- If your primary focus is raising the ambient temperature of a large, insulated room: A convection heater, which circulates warm air, is likely a more effective and energy-efficient solution.

Understanding that the quartz tube is a transparent window for heat, not the source of it, is the key to leveraging this technology's unique advantages.

Summary Table:

| Aspect | Quartz Tube Heating | Convection Heating |

|---|---|---|

| Heat Transfer Method | Radiant (Infrared Waves) | Convection (Warm Air) |

| Heating Speed | Instantaneous | Gradual |

| Efficiency for Spot Heating | Very High | Low |

| Best For | Targeted areas, industrial processes | Raising ambient temperature in enclosed spaces |

Ready to leverage the speed and precision of quartz tube heating in your lab or process?

At KINTEK, we specialize in high-performance lab equipment, including quartz tube heaters designed for reliability and efficiency. Whether you need rapid drying, precise thermal processing, or targeted spot heating, our solutions deliver direct energy transfer for superior results.

Contact us today to discuss your specific application and discover how KINTEK's expertise can enhance your laboratory's capabilities. Get in touch via our contact form and let our experts help you find the perfect heating solution.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the function of a high-vacuum tube furnace in graphene CVD? Optimize Synthesis for High-Quality Nanomaterials

- How does a vertical tube furnace ensure stability? Achieve Precise Molten Salt Electrochemical Testing

- Why are high-precision tube furnaces required for MSW syngas dry reforming? Optimize Catalyst Activity and H2:CO Ratios

- What is the temperature range of a tube furnace? From 1000°C to 1800°C for Your Lab Needs

- What is the primary role of a high-temperature tube furnace in CVD for CNTs? Master Precision Growth and Uniformity

- What are the benefits of a tube furnace? Achieve Superior Temperature & Atmosphere Control

- What is the purpose of using a tube furnace in the calcination process of NCM811 cathode materials? | KINTEK Solution

- What conditions does a high-vacuum atmosphere tube furnace provide during SiOC pyrolysis? Achieve Precise Ceramic Synthesis