In short, roll forming is a highly efficient manufacturing process used to bend flat sheet metal into long, uniform, and often complex profiles. It is the go-to method for creating components in high volumes, such as metal studs for construction, roofing panels, automotive parts, and solar panel racking. The process works by feeding a continuous coil of metal through a series of rollers, each progressively shaping the metal until the final cross-section is achieved.

The core principle to understand is this: Roll forming is chosen when consistency and speed are paramount for a very large quantity of identical parts. The significant upfront investment in tooling is justified by an extremely low per-part cost in mass production.

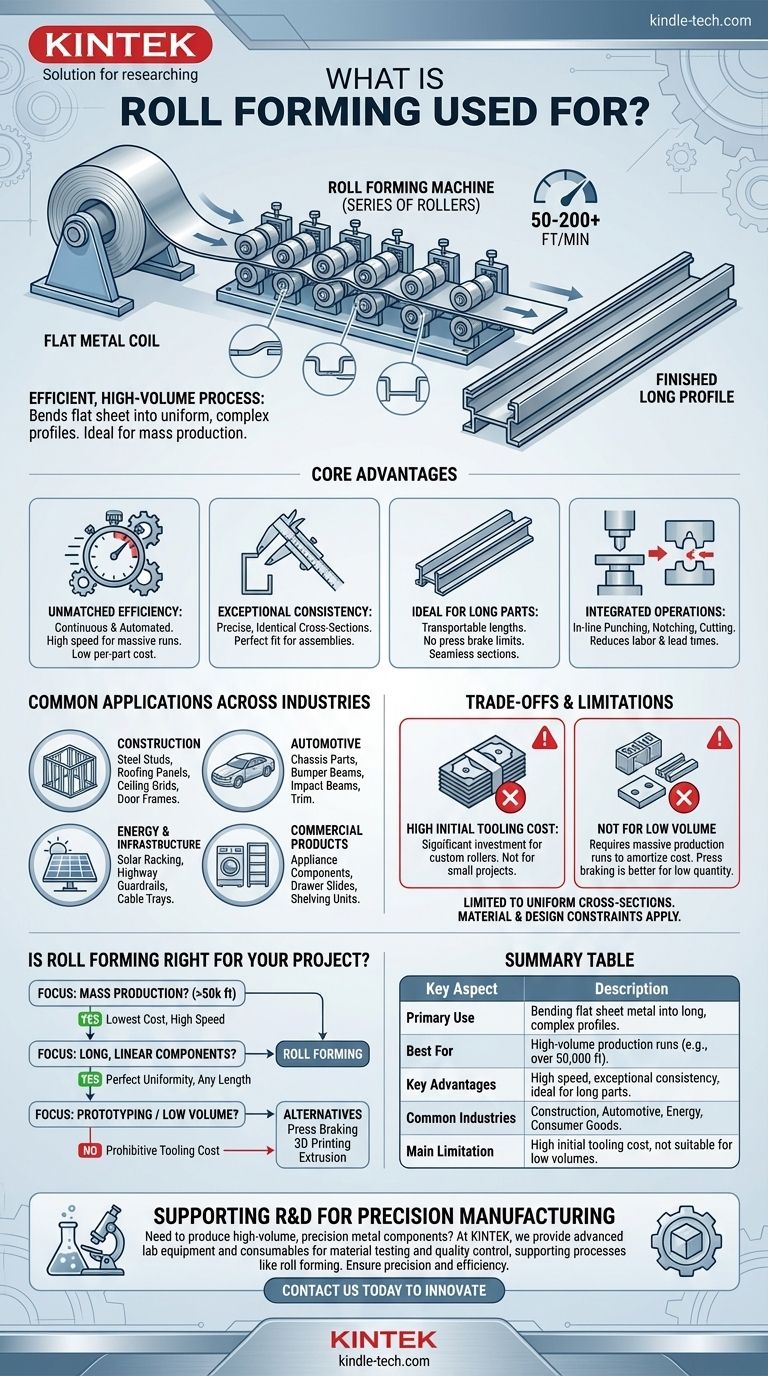

Why Choose Roll Forming? The Core Advantages

Roll forming isn't just one of many ways to bend metal; its unique characteristics make it the only logical choice for certain applications. The decision to use it hinges on a few key benefits.

Unmatched Efficiency for High Volumes

The roll forming process is continuous and automated. Once the metal coil is started, the machine can run with minimal supervision, producing finished parts at speeds of 50 to 200 feet per minute or more. This makes it incredibly cost-effective for production runs involving hundreds of thousands or millions of feet of a single profile.

Exceptional Consistency and Precision

Each station of rollers performs a precise, incremental bend. This method ensures that every foot of the final product has a virtually identical cross-section. This level of dimensional consistency is critical for parts that need to fit together perfectly, like in framing systems or assemblies.

Ideal for Long, Continuous Parts

Unlike press braking, which is limited by the length of the machine, roll forming can produce parts of nearly any transportable length. This is essential for products like gutters, roofing panels, and guardrails, which are often needed in long, seamless sections.

Integration of Secondary Operations

Modern roll forming lines can do more than just bend metal. It's common to integrate in-line processes like punching, notching, and cutting-to-length. This combines multiple manufacturing steps into one continuous operation, dramatically reducing labor costs and lead times.

Common Applications Across Industries

The combination of speed, consistency, and complexity makes roll forming a staple in numerous sectors. The products are so common that they are often overlooked.

Building and Construction

This is the largest market for roll formed parts. Key products include steel studs and tracks for framing, ceiling grid systems, metal roofing and siding panels, door and window frames, and structural purlins.

Automotive and Transportation

The automotive industry relies on roll forming for high-strength, lightweight structural components. This includes chassis parts, bumper beams, door impact beams, and decorative trim. The process guarantees the tight tolerances required for vehicle assembly.

Energy and Infrastructure

In the solar industry, the mounting racks that hold solar panels are almost exclusively roll formed. The process is also used for highway guardrails, electrical enclosures, and cable trays.

Commercial and Consumer Products

Countless everyday items rely on the process. This includes appliance components, drawer slides, shelving units, and office furniture components.

Understanding the Trade-offs and Limitations

No process is perfect for every scenario. To make an informed decision, you must understand the significant limitations of roll forming.

High Initial Tooling Costs

The primary barrier to entry is the cost of the roller tooling. A set of custom-hardened steel rollers designed to form a specific profile can cost tens or even hundreds of thousands of dollars. This investment makes the process entirely unsuitable for small projects.

Not Designed for Low-Volume Production

The high tooling cost must be amortized over a massive production run. If you only need a few hundred or a few thousand feet of a part, other methods like press braking or extrusion will be far more economical.

Limited to Uniform Cross-Sections

A roll formed part must have the same profile along its entire length. You cannot create a part that tapers or changes its shape midway through. The process is strictly for linear, constant-profile components.

Material and Design Constraints

The process works best with metals that have good formability, such as carbon steel, stainless steel, and aluminum. The thickness of the material is also a key constraint. Furthermore, very intricate bend radii and deep, narrow channels can be challenging or impossible to form correctly.

Is Roll Forming Right for Your Project?

Choosing the correct manufacturing process comes down to balancing cost, volume, and design requirements.

- If your primary focus is mass production of a single part: Roll forming offers the lowest per-part cost, highest speed, and best consistency for runs over 50,000 feet.

- If your primary focus is creating long, linear components: This process is uniquely capable of producing parts of virtually any transportable length with perfect uniformity.

- If your primary focus is prototyping or low-volume runs: Press braking, 3D printing, or metal extrusion are far more cost-effective alternatives due to the prohibitive tooling costs of roll forming.

Ultimately, roll forming is a powerful tool for manufacturing at scale, enabling the efficient production of the strong, consistent metal components that form the backbone of modern industry.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Use | Bending flat sheet metal into long, complex profiles. |

| Best For | High-volume production runs (e.g., over 50,000 ft). |

| Key Advantages | High speed, exceptional consistency, ideal for long parts. |

| Common Industries | Construction, Automotive, Energy, Consumer Goods. |

| Main Limitation | High initial tooling cost, not suitable for low volumes. |

Need to produce high-volume, precision metal components?

At KINTEK, we specialize in providing advanced lab equipment and consumables that support the research and development behind manufacturing processes like roll forming. Whether you're testing material formability or ensuring quality control for your metal profiles, our solutions help you achieve precision and efficiency.

Let KINTEK be your partner in innovation. Contact us today to discuss how our equipment can meet your laboratory's specific needs.

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Mini Planetary Ball Mill Machine for Laboratory Milling

People Also Ask

- What is meant by two high rolling mill? A Guide to Core Material Processing

- What is a two-high roll mill? Master Precise Material Compounding and Testing

- What is the disadvantage of a two-roll mill? Limited Thickness Reduction Due to Roll Flattening

- What is a two-roll differential speed mill? Achieve Superior Polymer Mixing & Dispersion

- What fillers for rubber compounds? Choose the Right Filler for Performance vs. Cost