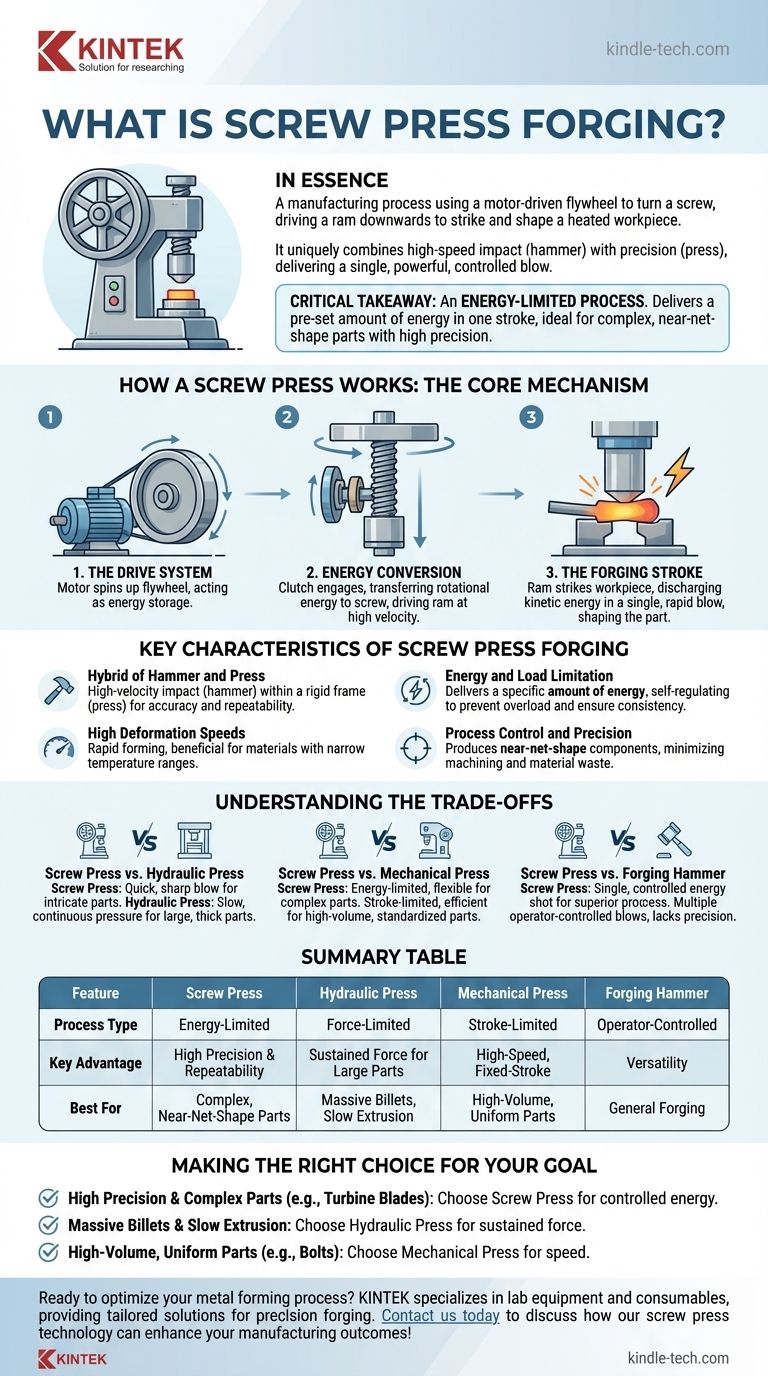

In essence, screw press forging is a manufacturing process that uses a large, motor-driven flywheel to turn a screw, which in turn drives a ram downwards to strike and shape a heated metal workpiece. It uniquely combines the high-speed impact of a forging hammer with the precision of a press, delivering a single, powerful, and highly controlled blow to form the part.

The critical takeaway is that screw press forging is an energy-limited process. Unlike other presses that stop at a specific position, a screw press delivers a pre-set amount of energy in one stroke, making it exceptionally suited for creating complex, near-net-shape parts with high precision.

How a Screw Press Works: The Core Mechanism

A screw press operates on a straightforward yet powerful principle of energy conversion. Understanding this mechanism reveals why it holds a unique position among forging technologies.

The Drive System

The process begins with an electric motor that spins up a large, heavy flywheel to a specific rotational speed. This flywheel, connected to a massive vertical screw, acts as the energy storage unit for the entire machine.

Energy Conversion

When the press is activated, a clutch engages, and the spinning flywheel's rotational energy is transferred to the screw. As the screw turns, it drives the connected ram (the moving part of the press) downward at a high velocity.

The Forging Stroke

The ram strikes the workpiece, which is placed on a stationary die. All the kinetic energy stored in the flywheel is discharged into the metal in a single, rapid blow. The stroke ends when this energy is fully dissipated by the deformation of the workpiece, at which point the ram stops automatically.

Key Characteristics of Screw Press Forging

The design of a screw press gives it a distinct set of operational characteristics that differentiate it from hydraulic or mechanical crank presses.

A Hybrid of Hammer and Press

Screw presses occupy a middle ground between forging hammers and other presses. They deliver a high-velocity impact similar to a hammer but do so within the rigid, guided frame of a press, offering far greater dimensional accuracy and repeatability.

Energy and Load Limitation

This is the defining feature. The machine is set to deliver a specific amount of energy, not to travel to a fixed bottom position. This self-regulation prevents die overload and ensures consistent energy is applied to each part, which is critical for material property control.

High Deformation Speeds

The ram's high speed allows for rapid forming of the workpiece. This is beneficial for materials with a narrow forging temperature range, as the part can be fully shaped before it cools significantly.

Process Control and Precision

Because the energy input is precisely controlled, screw presses excel at producing near-net-shape components. This means the forged part is very close to its final dimensions, minimizing the need for subsequent machining and reducing material waste.

Understanding the Trade-offs: Screw Press vs. Other Methods

No single forging method is universally superior; the choice depends entirely on the part's geometry, material, and production volume.

Screw Press vs. Hydraulic Press

A hydraulic press, which is rated by the maximum force it can generate (often in tons), applies pressure slowly and continuously. This is ideal for very large, thick parts that require a slow "squeeze." In contrast, a screw press delivers a quick, sharp blow, which is better for filling intricate die cavities and working with materials sensitive to deformation rates.

Screw Press vs. Mechanical Press

A conventional mechanical (or crank) press is stroke-limited. Its ram travels to a fixed bottom position on every cycle, regardless of the workpiece. This makes it excellent for high-volume, standardized production runs. A screw press, being energy-limited, offers more flexibility for complex parts where the final thickness might vary slightly.

Screw Press vs. Forging Hammer

A forging hammer relies on the operator's skill to deliver multiple blows of varying intensity. While versatile, it lacks the precision and repeatability of a screw press. The single, controlled energy shot from a screw press provides far superior process control and consistency.

Making the Right Choice for Your Goal

Selecting the correct forging process requires aligning the technology's strengths with your specific manufacturing objective.

- If your primary focus is high precision and complex, near-net-shape parts (like turbine blades or surgical implants): The controlled energy and repeatability of a screw press make it the superior choice.

- If your primary focus is shaping massive billets or performing slow extrusion-type forging: The sustained, immense force of a hydraulic press is necessary.

- If your primary focus is extremely high-volume production of simpler, uniform parts (like standard bolts or fittings): The speed and fixed-stroke nature of a mechanical crank press is the most efficient solution.

Ultimately, understanding the fundamental difference between energy-limited and force-limited forging is the key to unlocking the best possible manufacturing outcome.

Summary Table:

| Feature | Screw Press | Hydraulic Press | Mechanical Press | Forging Hammer |

|---|---|---|---|---|

| Process Type | Energy-Limited | Force-Limited | Stroke-Limited | Operator-Controlled |

| Key Advantage | High Precision & Repeatability | Sustained Force for Large Parts | High-Speed, Fixed-Stroke | Versatility |

| Best For | Complex, Near-Net-Shape Parts | Massive Billets, Slow Extrusion | High-Volume, Uniform Parts | General Forging with Operator Skill |

Ready to optimize your metal forming process? KINTEK specializes in lab equipment and consumables, providing tailored solutions for precision forging and material testing. Whether you're developing complex components or need reliable equipment for your laboratory, our expertise ensures you achieve superior results with high repeatability and minimal waste. Contact us today to discuss how our screw press technology and support can enhance your manufacturing outcomes!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Small Injection Molding Machine for Lab Use

People Also Ask

- How do you prepare a sample for XRF analysis? Master the Key Methods for Accurate Results

- What are the hazards of press machine? Mitigate Crushing, Amputation, and Other Critical Risks

- How does a laboratory hydraulic press contribute to the electrochemical performance testing of LiMOCl4? Achieve Density

- What are the factors that affect pellet quality? Master KBr Pellet Prep for Flawless FTIR Results

- What is the role of a laboratory hydraulic press in LLZO pellet preparation? Enhance Ionic Conductivity via Cold Pressing

- What task does a laboratory hydraulic press perform in Fe@C specimen preparation? Optimize Electromagnetic Testing

- At what temperature do hydraulics stop working? Avoid Catastrophic Failure in Extreme Conditions

- What are the three applications of a hydraulic press? From Metal Forming to Lab Precision