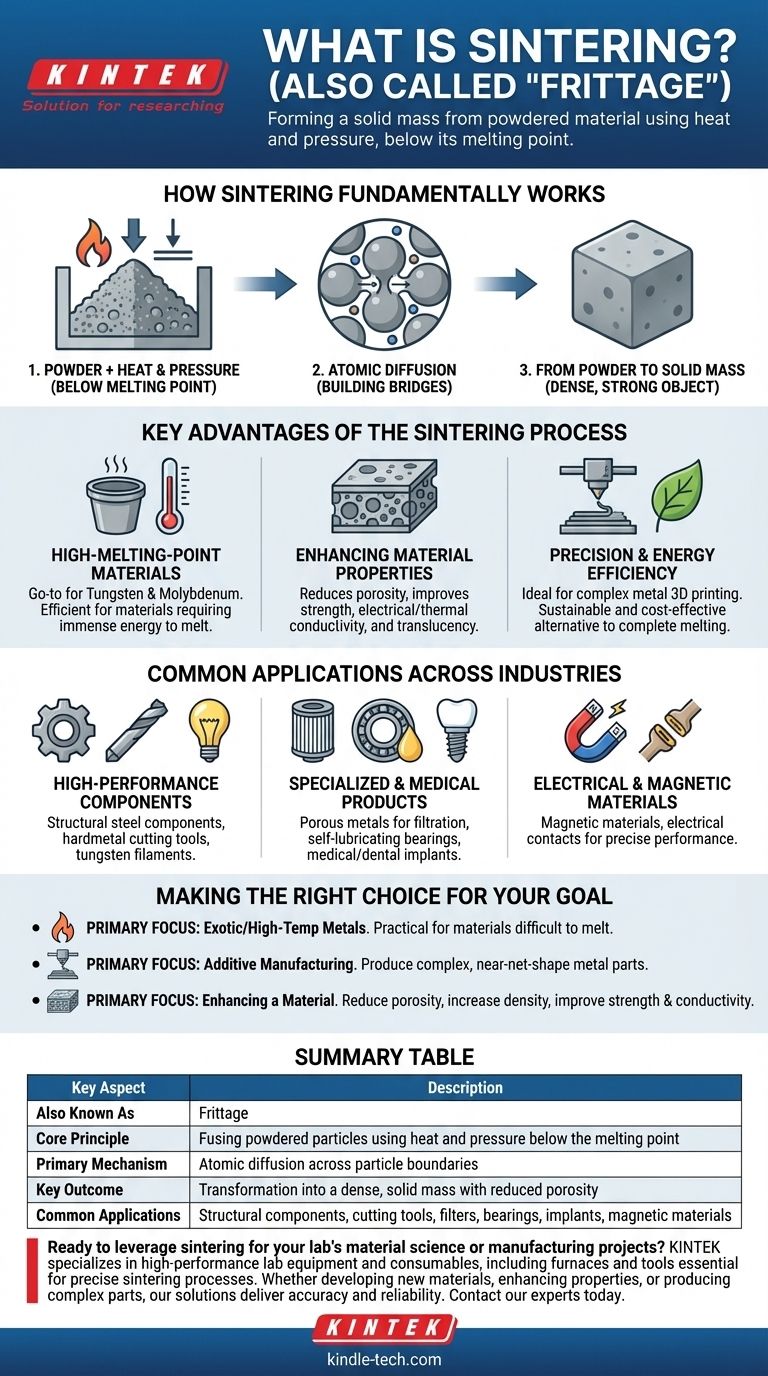

By another name, sintering is also called 'frittage'. Both terms describe the process of forming a solid mass from powdered material using heat and pressure, but critically, without melting it into a liquid state.

Sintering is a foundational materials science process that compacts and fuses particles together. Its true value lies in its ability to create dense, strong objects from materials with extremely high melting points, making it indispensable for advanced manufacturing.

How Sintering Fundamentally Works

Sintering might seem complex, but its core principle is about encouraging individual particles to join together into a single, coherent piece.

The Role of Heat and Pressure

The process applies significant heat and pressure to a powdered material. This energy is kept below the material's melting point, which is the key differentiator from casting or welding.

The Mechanism of Atomic Diffusion

The applied energy excites the atoms within the material. This allows atoms to migrate, or diffuse, across the boundaries of individual particles, effectively building bridges between them.

From Powder to Solid Mass

As these atomic bridges form and multiply, the gaps (or pores) between the particles shrink. The particles fuse together, transforming the loose powder into a dense, solid object with significantly enhanced strength.

Key Advantages of the Sintering Process

Engineers and manufacturers choose sintering not just as an alternative to melting, but for its unique strategic benefits.

Working with High-Melting-Point Materials

Sintering is the go-to method for materials like tungsten and molybdenum. Melting these metals requires immense energy and specialized equipment, whereas sintering can form them into solid parts much more efficiently.

Enhancing Material Properties

The process fundamentally changes a material's structure. By reducing porosity, sintering can dramatically improve properties like strength, electrical conductivity, thermal conductivity, and even translucency in certain ceramics.

Precision and Energy Efficiency

In applications like metal 3D printing, sintering allows for the creation of intricate, custom forms with excellent consistency. Because it avoids the high energy cost of complete melting, it is often a more sustainable and cost-effective manufacturing route.

Common Applications Across Industries

Sintering is not a niche laboratory technique; it is a critical manufacturing process used to create a vast range of products we rely on daily.

High-Performance Components

Many demanding applications depend on sintered parts. This includes structural steel components, hardmetal cutting tools, and the tungsten filaments found in lighting and electronics.

Specialized and Medical Products

The process is used to create porous metals for filtration, self-lubricating bearings (where oil is held in the pores), and high-purity medical and dental implants.

Electrical and Magnetic Materials

Sintering is also essential for manufacturing certain types of magnetic materials and electrical contacts, where precise material density and properties are critical for performance.

Making the Right Choice for Your Goal

Understanding when to leverage sintering is key to solving specific engineering challenges.

- If your primary focus is working with exotic or high-temp metals: Sintering is the most practical and energy-efficient method for creating solid parts from materials that are difficult or impossible to melt.

- If your primary focus is additive manufacturing: Use sintering-based 3D printing to produce complex, near-net-shape metal parts with excellent material properties.

- If your primary focus is enhancing a material: Apply sintering to reduce porosity, increase density, and improve the strength and conductivity of a powdered starting material.

Ultimately, sintering empowers us to engineer materials at an atomic level, turning simple powders into highly functional, robust components.

Summary Table:

| Key Aspect | Description |

|---|---|

| Also Known As | Frittage |

| Core Principle | Fusing powdered particles using heat and pressure below the melting point |

| Primary Mechanism | Atomic diffusion across particle boundaries |

| Key Outcome | Transformation into a dense, solid mass with reduced porosity |

| Common Applications | Structural components, cutting tools, filters, bearings, medical/dental implants, magnetic materials |

Ready to leverage sintering for your lab's material science or manufacturing projects? KINTEK specializes in high-performance lab equipment and consumables, including furnaces and tools essential for precise sintering processes. Whether you're developing new materials, enhancing properties, or producing complex parts, our solutions deliver the accuracy and reliability you need. Contact our experts today to discuss how we can support your sintering applications and help you achieve superior results.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects