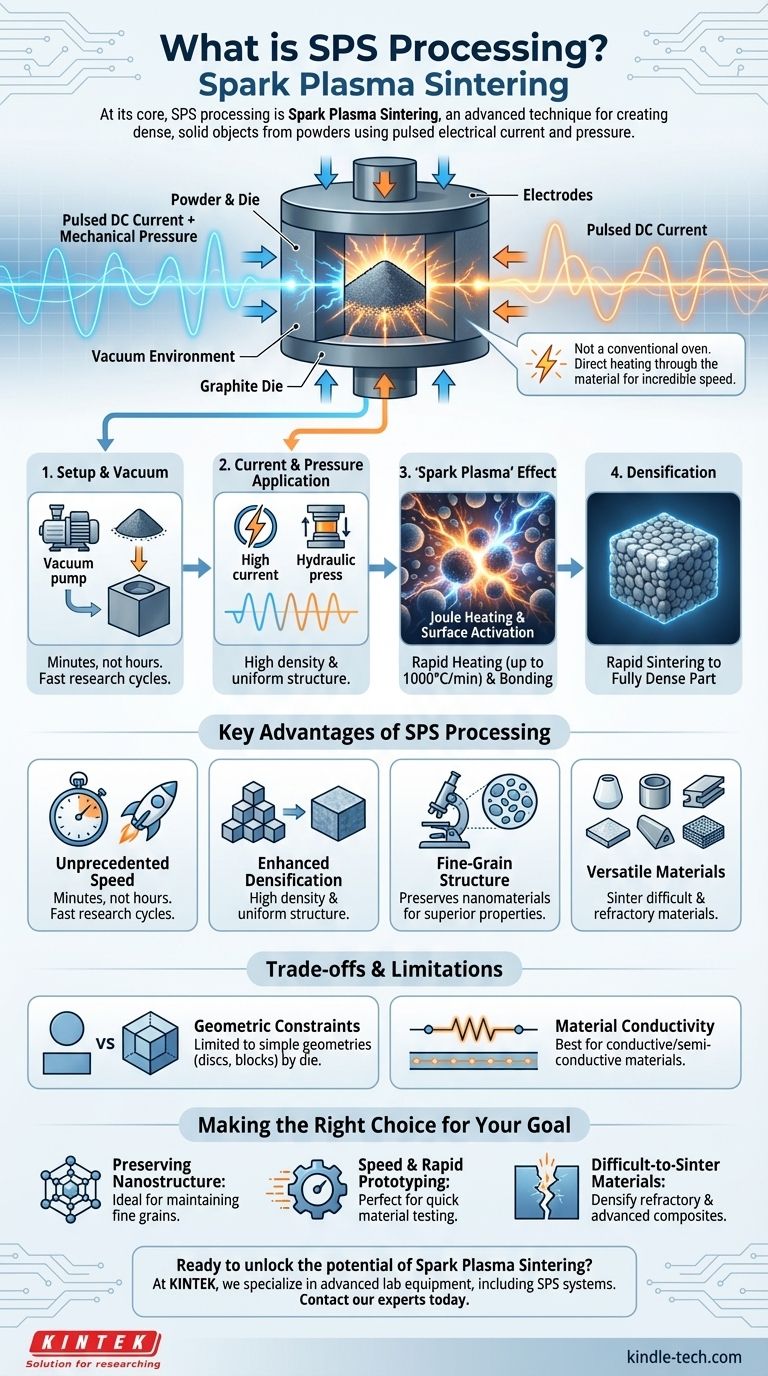

At its core, the term "SPS processing" almost exclusively refers to Spark Plasma Sintering, an advanced materials science technique for creating dense, solid objects from powders. While SPS can also stand for Secure Payment System in finance, the context of "processing" points directly to this specific manufacturing method that uses pulsed electrical current and pressure to rapidly fuse materials together.

Spark Plasma Sintering is not a conventional oven-based heating method. Instead, it uses the material itself as a heating element, applying a powerful pulsed DC current and mechanical pressure to achieve incredibly fast sintering, preserving unique material properties that would be lost in slower processes.

What is Spark Plasma Sintering (SPS)?

Spark Plasma Sintering is a modern sintering technique, a type of powder metallurgy process. It's used to transform a powder compact into a solid, dense object without melting it.

Think of it as an extremely fast and powerful version of hot pressing. Instead of just heating the outside of a mold and waiting for the heat to transfer, SPS passes electricity through the mold and the powder itself.

This direct heating method allows for extraordinarily high heating rates—sometimes exceeding 1000°C per minute—drastically shortening the time required to form a solid part.

How Does the SPS Process Work?

The process is a precise interplay of electrical energy, mechanical force, and a vacuum environment, all happening within a specialized machine.

The Core Components: Powder and Die

First, the raw material powder is loaded into a conductive die, which is almost always made of graphite. This entire assembly is placed between two electrodes inside a vacuum chamber.

The Dual Forces: Electric Current and Pressure

Once the chamber is evacuated, two things happen simultaneously. A large mechanical pressure is applied to the die, compressing the powder. At the same time, the machine generates a powerful, pulsed direct current (DC) that flows through the electrodes, the die, and the powder.

The "Spark Plasma" Effect

The pulsed current creates two critical effects. The primary effect is Joule heating, where the electrical resistance of the graphite die and the powder itself generates intense, rapid, and uniform heat.

Additionally, the high current density can generate momentary sparks or plasma discharges between the individual powder particles. This effect helps clean and activate the particle surfaces, promoting diffusion and accelerating the bonding process.

This combination of intense heat, surface activation, and constant pressure forces the powder particles to fuse together and densify very quickly.

Key Advantages of SPS Processing

The unique mechanism of SPS gives it several significant advantages over traditional sintering methods like hot pressing or furnace sintering.

Unprecedented Speed

The most significant benefit is speed. With heating and cooling rates that can be orders of magnitude faster than conventional furnaces, a process that might take many hours can be completed in minutes. This dramatically shortens research and production cycles.

Enhanced Densification and Fine-Grain Structure

The rapid cycle time inhibits grain growth. For many advanced materials, especially nanomaterials, preserving a fine-grained microstructure is critical to achieving desired properties like high strength or specific magnetic behaviors. SPS excels at creating fully dense parts while keeping the grain size extremely small.

Versatility with Advanced Materials

SPS has become the preferred technique for materials that are notoriously difficult to sinter. This includes extremely refractory materials (with very high melting points), metastable materials, and composites made of dissimilar substances.

Understanding the Trade-offs and Limitations

While powerful, SPS is not a universal solution. Its specialized nature comes with practical considerations.

Geometric and Size Constraints

The size and shape of the final component are limited by the graphite die. Creating large or highly complex shapes can be challenging and expensive, making it better suited for producing relatively simple geometries like discs, cylinders, or blocks.

Material Conductivity

The process works most effectively with electrically conductive or semi-conductive powders and dies. While insulating materials like some ceramics can be sintered, it often requires special techniques or conductive aids, adding complexity to the process.

Equipment and Cost

SPS equipment is highly specialized and represents a significant capital investment compared to a standard furnace. The complexity of the process—requiring a vacuum, high currents, and high pressures—also demands skilled operation.

Making the Right Choice for Your Goal

Deciding to use SPS depends entirely on the material you are working with and the final properties you need to achieve.

- If your primary focus is preserving nanostructure: SPS is the leading choice for densifying nanomaterials without the grain growth that destroys their unique properties.

- If your primary focus is speed and rapid prototyping: The ability to run cycles in minutes makes SPS an unparalleled tool for quickly testing new material compositions and alloys.

- If your primary focus is working with difficult-to-sinter materials: SPS provides the extreme conditions necessary to densify refractory ceramics, cermets, and other advanced composites that fail to consolidate in conventional furnaces.

Ultimately, Spark Plasma Sintering empowers engineers and scientists to create next-generation materials by controlling their structure at the microscopic level.

Summary Table:

| Feature | Benefit |

|---|---|

| Rapid Heating/Cooling | Process completion in minutes, not hours; ideal for rapid prototyping. |

| Fine-Grain Preservation | Inhibits grain growth, crucial for nanomaterials and high-strength components. |

| Versatile Material Sintering | Effective with refractory materials, composites, and difficult-to-sinter powders. |

| Direct Resistance Heating | Uniform and efficient heating by passing current through the powder and die. |

Ready to unlock the potential of Spark Plasma Sintering for your lab?

At KINTEK, we specialize in providing advanced lab equipment, including SPS systems, to help you achieve rapid densification and preserve the unique properties of your advanced materials. Whether you're working with nanomaterials, refractory ceramics, or complex composites, our expertise can help you accelerate your research and development.

Contact our experts today to discuss how SPS processing can enhance your materials science projects and meet your specific laboratory needs.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the significance of graphite molds in CuCr50 vacuum hot pressing? Enhance Alloy Density and Purity

- Is SPS additive manufacturing? Unpacking the Key Differences in Powder-Based Processes

- Why Use a Vacuum Hot Press for SiCp/6061 Composites? Ensure Pure Interface Bonding and Maximum Density

- How does a hot press sintering furnace facilitate Ti/Al3Ti composite synthesis? Achieve Precision In Situ Fabrication

- What roles do graphite molds play during vacuum hot pressing? Optimize Alloy Powder Densification & Precision

- What is the process of hot-pressing sintering? Achieve Superior Density for High-Performance Materials

- What is spark plasma sintering of materials? A Guide to High-Speed, High-Performance Densification

- What role does a high-purity graphite mold play during hot pressing? Optimize Boron Carbide Sintering at 1850°C