To be precise, sputter ceramic film is a high-performance window film manufactured using a sophisticated process called sputtering. In this high-tech vacuum process, durable ceramic materials are broken down into atomic-sized particles and then permanently embedded into layers of polyester film. This method creates a final product known for exceptional heat rejection, superior clarity, and a lifespan that far exceeds traditional dyed or coated films.

The key isn't just the ceramic material itself, but the sputtering process used to apply it. This manufacturing technique produces a fundamentally more durable and optically clear film that won't fade, bubble, or interfere with electronic signals.

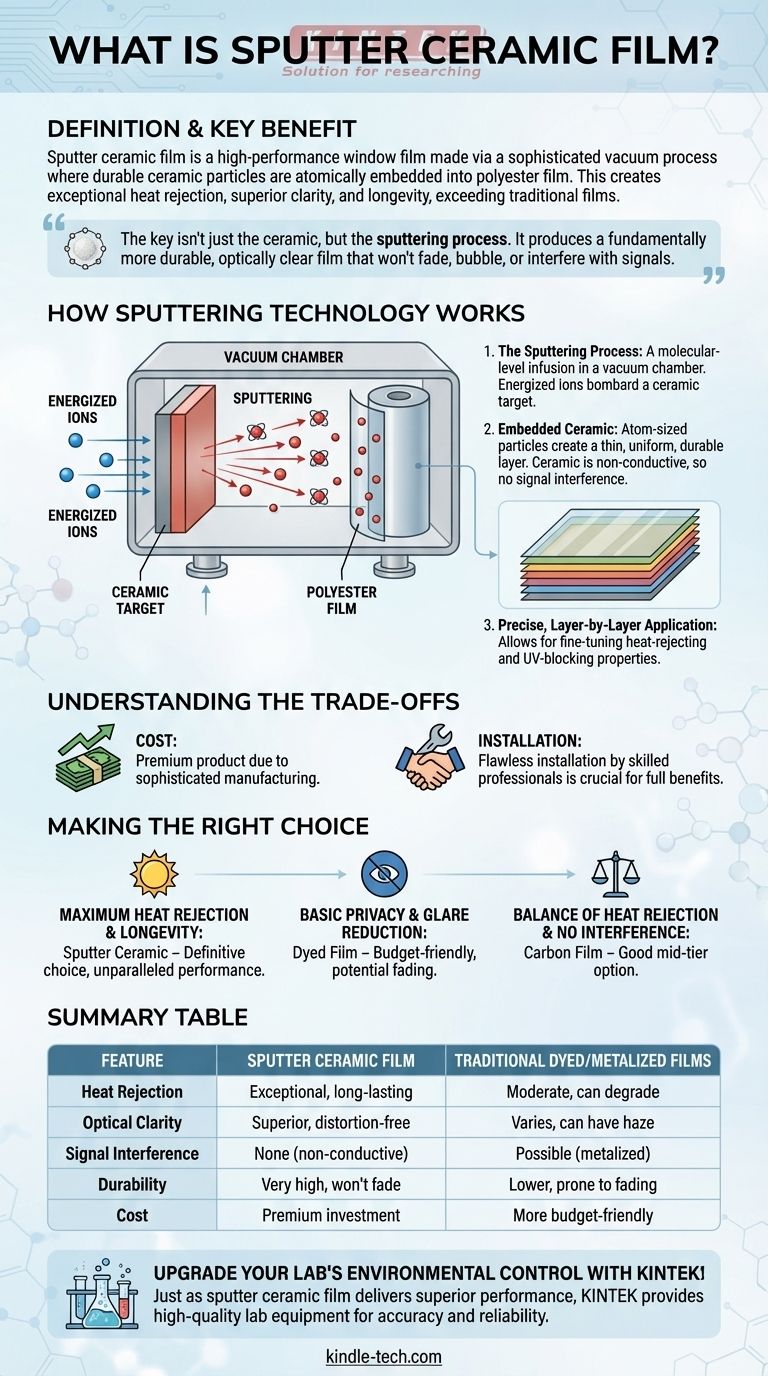

How Sputtering Technology Works

To understand the value of this film, you must first understand the manufacturing process that sets it apart. Sputtering is not a simple coating; it is a molecular-level infusion.

The Sputtering Process Explained

Think of sputtering as a microscopic, atomic-level sandblasting process in reverse. Inside a vacuum chamber, a target material (in this case, a block of resilient ceramic) is bombarded with energized ions.

This bombardment causes microscopic particles of the ceramic to "sputter" off the target. These atom-sized particles then travel and embed themselves directly into the polyester film, creating an incredibly thin, uniform, and durable layer.

The Advantage of Embedded Ceramic

The material being sputtered onto the film is a non-metallic ceramic. This is critical.

Unlike older metalized films, ceramic is non-conductive. This means it will not interfere with electronic signals like your cell phone, GPS, or radio. It provides powerful heat rejection without the downsides of metal.

A Precise, Layer-by-Layer Application

The sputtering process allows for extreme precision. Manufacturers can deposit multiple layers of different materials, atom by atom, to fine-tune the film's properties.

This results in a film that is packed with heat-rejecting and UV-blocking technology while remaining exceptionally clear and distortion-free.

Understanding the Trade-offs

While sputter ceramic film represents the peak of current technology, it's essential to consider the full picture.

The Primary Factor: Cost

The sophisticated equipment and complex physics involved in the sputtering process make it significantly more expensive to produce than other film types. Sputter ceramic films are a premium product with a price tag to match.

Installation Matters

To realize the full benefits of superior optical clarity and performance, the installation must be flawless. Choosing a reputable, highly skilled installer is just as important as choosing the film itself, which can add to the overall investment.

Making the Right Choice for Your Goal

Selecting the right window film depends entirely on balancing your budget with your performance expectations.

- If your primary focus is maximum heat rejection and longevity: Sputter ceramic is the definitive choice, offering unparalleled performance that will not degrade over time.

- If your primary focus is a basic level of privacy and glare reduction on a tight budget: A standard dyed film will suffice, but be prepared for potential fading and lower heat rejection.

- If your primary focus is a balance of good heat rejection without signal interference: A quality carbon film is a solid mid-tier option, though it won't match the durability or clarity of sputtered ceramic.

Ultimately, choosing a sputter ceramic film is an investment in superior technology for long-term comfort and performance.

Summary Table:

| Feature | Sputter Ceramic Film | Traditional Dyed/Metalized Films |

|---|---|---|

| Heat Rejection | Exceptional, long-lasting | Moderate, can degrade over time |

| Optical Clarity | Superior, distortion-free | Varies, can have haze or distortion |

| Signal Interference | None (non-conductive ceramic) | Possible (with metalized layers) |

| Durability/Lifespan | Very high, won't fade or bubble | Lower, prone to fading and failure |

| Cost | Premium investment | More budget-friendly |

Upgrade your lab's environmental control with precision-engineered solutions from KINTEK! Just as sputter ceramic film delivers superior performance through advanced manufacturing, KINTEK provides high-quality lab equipment and consumables designed for accuracy, durability, and reliability. Whether you need precise temperature management, material processing, or environmental simulation, our products are built to meet the rigorous demands of your laboratory. Contact our experts today to find the perfect equipment to enhance your research and operational efficiency!

Visual Guide

Related Products

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminum-Plastic Flexible Packaging Film for Lithium Battery Packaging

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

People Also Ask

- How does biomass energy compare with other renewables? The Pros and Cons of On-Demand Power

- What is the temperature involved in the brazing process? Master the 4 Critical Phases for Perfect Joints

- Why must a laboratory oven be used for the dehydration of sodium molybdate precursors? Ensure Synthesis Success

- What is the use of drying oven in laboratory? Achieve Uniform Heat for Drying, Sterilizing, and Curing

- What are the end products of pyrolysis? Turn Waste into Biochar, Oil, and Syngas

- What are the different types of pyrolysis units? Choose the Right Process for Your Biofuel or Biochar Goal

- What is the energy consumption of conventional ultra-low temperature (ULT) freezers? Managing High Energy Costs

- What is the function of a laboratory orbital shaker during the Fenton reaction? Optimize Leather Wastewater Treatment