In essence, press forging is the preferred method for manufacturing large, complex, and high-strength metal components where structural integrity is non-negotiable. It is the go-to process for critical parts in demanding industries like aerospace, energy, and automotive, creating components such as aircraft landing gear, turbine discs, and heavy-duty crankshafts.

The core advantage of press forging lies in its slow, controlled application of immense force. Unlike the sharp impacts of a hammer, a press squeezes the metal, ensuring deep and uniform refinement of the material's internal grain structure for superior strength and fatigue resistance.

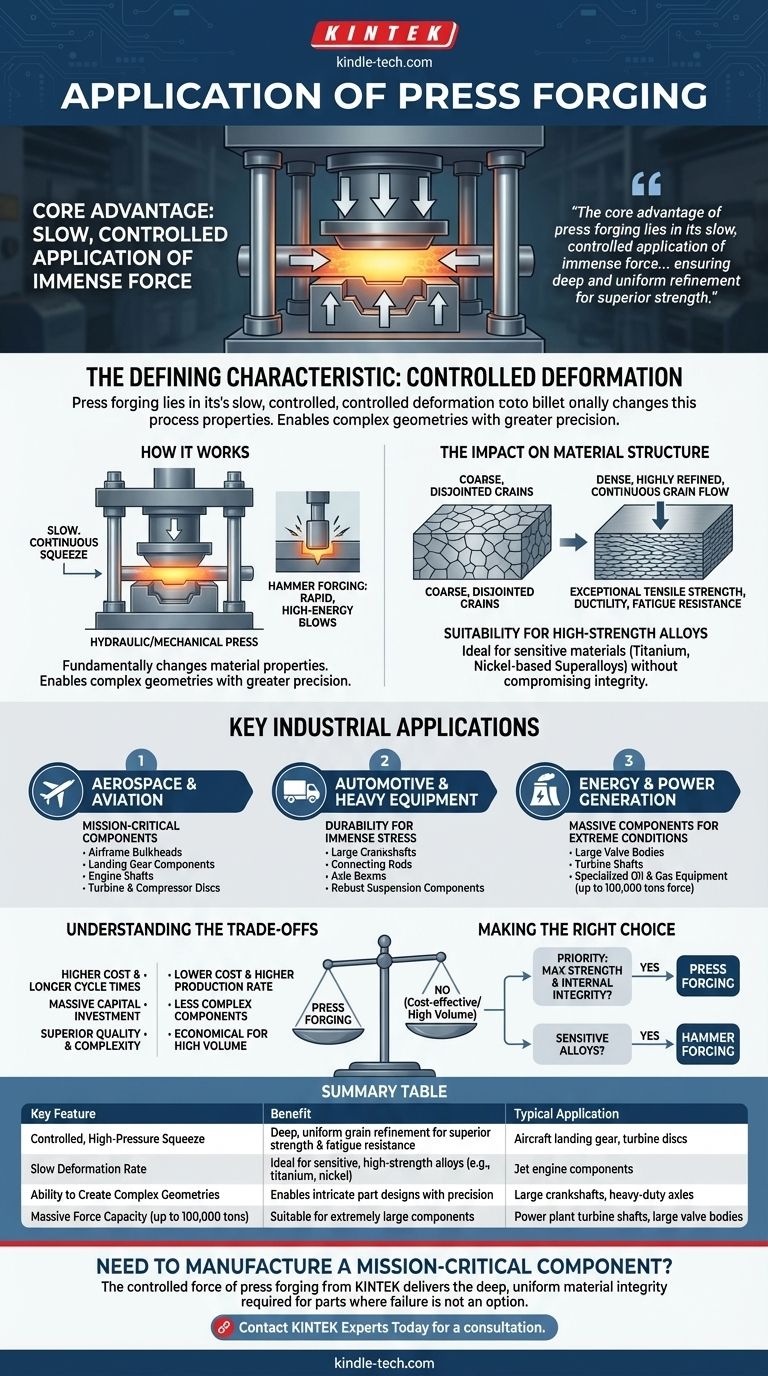

The Defining Characteristic: Controlled Deformation

Press forging's unique applications stem directly from how it shapes metal. The process relies on a continuous, high-pressure squeeze from a hydraulic or mechanical press, which fundamentally changes the material properties.

How Press Forging Works

A press uses one or more strokes to slowly force a heated metal billet to conform to the shape of a die. This gradual compression is fundamentally different from hammer forging, which uses a series of rapid, high-energy blows.

This slow squeeze allows the metal to flow smoothly into intricate die cavities, enabling the creation of more complex geometries with greater precision.

The Impact on Material Structure

The primary benefit of this controlled pressure is its effect on the metal's internal grain structure. The squeezing action kneads the material thoroughly, breaking down coarse grains and eliminating internal voids or porosity.

This results in a dense, highly refined, and continuous grain flow that follows the contour of the part. This homogenous structure provides exceptional tensile strength, ductility, and resistance to fatigue and impact, which is why it's mandated for many mission-critical components.

Suitability for High-Strength Alloys

Many advanced materials, such as titanium and nickel-based superalloys used in jet engines and turbines, are sensitive to strain rates. They can crack or fail when subjected to the sharp, high-energy impacts of a hammer.

Press forging's slow, controlled deformation is ideal for these materials, allowing them to be shaped without compromising their structural integrity.

Key Industrial Applications

The combination of size capability, precision, and superior material properties makes press forging essential for a range of high-performance industries.

Aerospace and Aviation

This is the quintessential application for press forging. It is used to create parts where failure is not an option, including airframe bulkheads, landing gear components, engine shafts, and the turbine and compressor discs at the heart of a jet engine.

Automotive and Heavy Equipment

For heavy-duty vehicles and machinery, press forging delivers the durability needed to withstand immense operational stress. Key parts include large crankshafts, connecting rods, axle beams, and robust suspension components for trucks and construction equipment.

Energy and Power Generation

The energy sector relies on press forging for massive components that must operate under extreme pressure and temperature. This includes large valve bodies, turbine shafts for power plants, and specialized equipment for oil and gas exploration, with presses capable of exerting up to 100,000 tons of force for the largest parts.

Understanding the Trade-offs

While press forging produces superior components, it is not the solution for every application. Understanding its limitations is key to making an informed manufacturing decision.

Cost and Production Speed

Press forging is generally a slower and more deliberate process than hammer forging. The cycle times are longer, which translates to a lower production rate and often a higher cost per part.

Scale and Capital Investment

The machinery involved is massive and represents a significant capital investment. Hydraulic presses with capacities of 60,000 to 82,000 tons are enormous, complex installations, meaning this capability is concentrated in a few specialized facilities worldwide.

When Press Forging Isn't the Answer

For smaller, less complex components where the absolute highest strength is not a design driver, press forging may be overkill. Hammer forging or casting can often provide a more economical solution for high-volume production of simpler parts.

Making the Right Choice for Your Goal

Selecting a forging process requires balancing the demand for performance against economic and production realities.

- If your primary focus is maximum strength and internal integrity for a large or complex part: Press forging is the superior choice due to its deep, uniform material deformation.

- If your primary focus is cost-effective, high-volume production of smaller, simpler parts: Hammer forging often provides a more economical and faster solution.

- If you are working with sensitive, high-strength alloys like titanium or nickel: The controlled force of press forging is essential to prevent material cracking and ensure reliability.

Ultimately, selecting press forging is a strategic decision to prioritize material quality and structural reliability above all else.

Summary Table:

| Key Feature | Benefit | Typical Application |

|---|---|---|

| Controlled, High-Pressure Squeeze | Deep, uniform grain refinement for superior strength and fatigue resistance | Aircraft landing gear, turbine discs |

| Slow Deformation Rate | Ideal for sensitive, high-strength alloys (e.g., titanium, nickel) | Jet engine components |

| Ability to Create Complex Geometries | Enables intricate part designs with precision | Large crankshafts, heavy-duty axles |

| Massive Force Capacity (up to 100,000 tons) | Suitable for extremely large components | Power plant turbine shafts, large valve bodies |

Need to manufacture a mission-critical component that demands the highest strength and reliability?

The controlled force of press forging from KINTEK delivers the deep, uniform material integrity required for parts where failure is not an option. Our expertise in lab equipment and consumables supports the entire manufacturing lifecycle, from material testing to final product validation.

Let's discuss how our solutions can enhance your project's success. Contact our experts today for a consultation tailored to your specific needs in aerospace, automotive, or energy.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What role does a laboratory hydraulic press play during cold-pressing? Optimize Your Vacuum Hot-Pressing Results

- What are the safety procedures for hydraulic press? A Guide to Accident-Free Operation

- What can XRF identify? Discover the Elements in Your Materials with Precision

- What is the effect of particle size on XRF measurements? Achieve Accurate & Reliable Results

- What is uniaxial pressing pressure? Achieve Optimal Powder Compaction for Stronger Parts

- What is the role of a laboratory hydraulic press in the solid-phase reduction of red mud? Optimize Sponge Iron Quality

- Which press is suitable for heavy work? Choose the Right Press for Demanding Industrial Tasks

- How does a uniaxial hydraulic press contribute to the formation of LCO and LATP composite green bodies? Expert Insights