The best frequency for induction heating is not a single value; it is determined entirely by your specific goal for the material. The core principle is that frequency controls how deeply the heat penetrates a workpiece. High frequencies create shallow heat near the surface, while low frequencies penetrate much deeper.

The central decision in induction heating revolves around a single trade-off: higher frequencies concentrate heat on the surface for tasks like case hardening, while lower frequencies drive heat deeper into the part for processes like forging or deep hardening of large components.

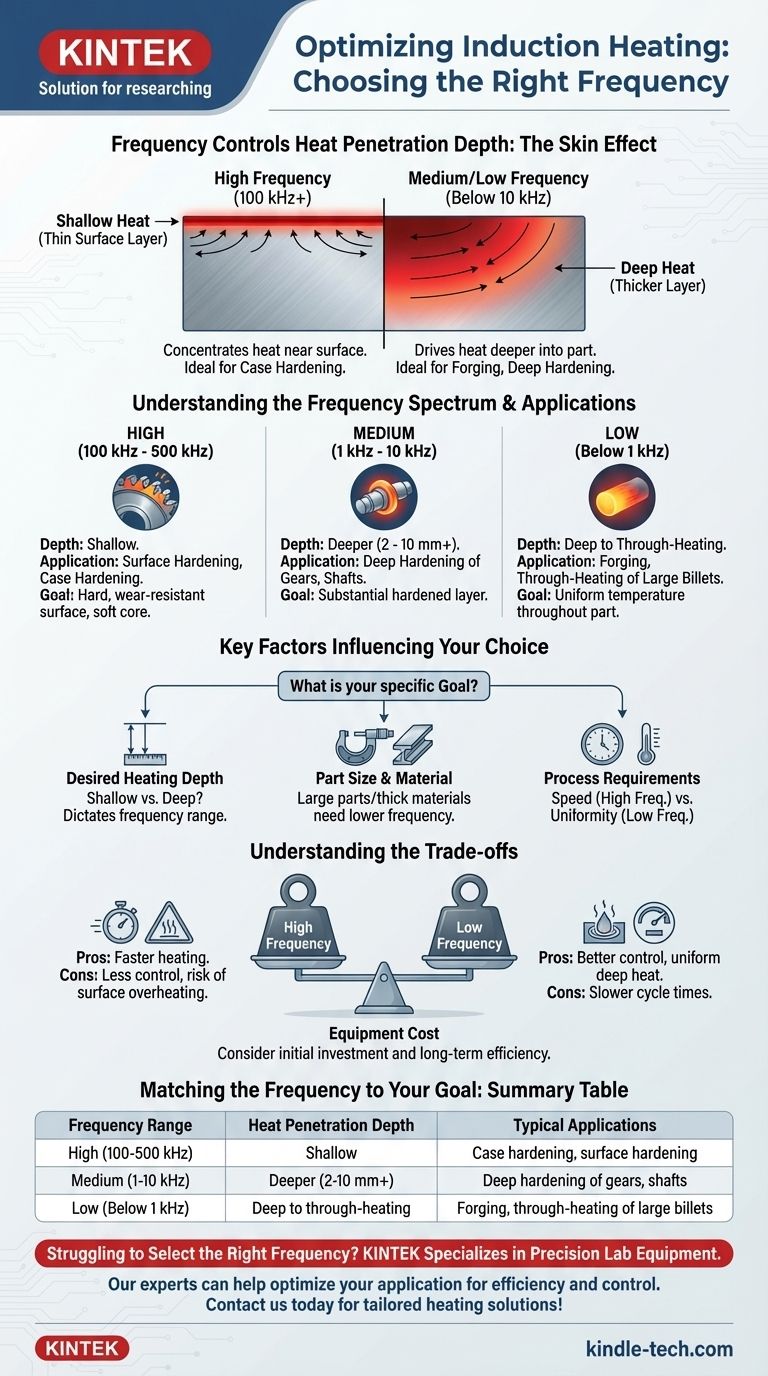

The Fundamental Principle: Frequency and Heat Depth

To select the right frequency, you must first understand how it dictates the behavior of the heating process. This is governed by a phenomenon known as the "skin effect."

How Induction Heating Works

Induction heating uses a powerful, alternating magnetic field to induce electrical currents, called eddy currents, within a conductive workpiece. The material's natural resistance to the flow of these currents generates precise, rapid heat without any physical contact.

The "Skin Effect": Why Frequency Matters

The frequency of the alternating current is the critical variable. As the frequency increases, the induced eddy currents are forced to flow in a thinner layer near the surface of the part. This is called the skin effect.

This relationship gives you direct control over the heating profile. By selecting a frequency, you are also selecting the depth of heat penetration.

High Frequency for Surface Heating

High-frequency induction heating typically operates in the 100 kHz to 500 kHz range. Because of the strong skin effect at these frequencies, heat is generated in a very thin layer at the material's surface.

This makes it ideal for applications requiring a hard, wear-resistant surface while leaving the core of the component soft and ductile.

Medium Frequency for Deeper Penetration

Medium-frequency heating operates at a lower range, generally between 1 kHz and 10 kHz. The lower frequency allows the induced currents to travel deeper into the workpiece.

This results in an effective hardening depth of 2 to 10 mm or more, making it suitable for treating larger parts like gears and shafts that require a substantial hardened layer, not just a surface treatment.

Key Factors Influencing Your Choice

While the desired heat depth is the primary driver, other factors must be considered to optimize the process.

Desired Heating Depth

This is the most important question to answer. Are you performing a shallow case hardening on a small shaft, or do you need to heat an entire billet through for forging? The answer will immediately point you toward a high or low frequency.

Part Size and Material

The size of the workpiece is crucial. Large, thick parts require lower frequencies to allow the energy to penetrate to the core effectively. The material's specific electrical and magnetic properties also influence how efficiently it couples with the magnetic field at a given frequency.

Process Requirements

Consider the overall manufacturing goal. Is speed the priority? High-frequency surface hardening can be extremely fast. Is uniformity the priority? A lower frequency "soaking" heat may be necessary to ensure a large part is heated evenly.

Understanding the Trade-offs

Choosing a frequency involves balancing competing factors. An incorrect choice can lead to inefficient heating or damaged parts.

Efficiency vs. Control

Higher frequencies often transfer energy into the part more quickly, leading to faster cycle times. However, this rapid surface heating can be difficult to control and may not be suitable when a gradual, deep heat is required.

Overheating the Surface

A common pitfall is using a frequency that is too high for the desired depth. This will cause the surface to heat far too quickly, potentially melting or compromising it long before the core has reached the target temperature.

Equipment Cost

The cost of the induction heating equipment must also be considered. As noted in process analyses, it's sometimes possible for a higher-power, medium-frequency machine to achieve a similar result as a lower-power, high-frequency one, which can impact the initial investment.

Matching the Frequency to Your Goal

Your application dictates the optimal frequency. There is no universally "best" option, only the right tool for the job.

- If your primary focus is thin-layer surface hardening: A high frequency (100 kHz+) is the correct choice to concentrate energy on the surface.

- If your primary focus is deep case hardening on large parts: A medium frequency (1-10 kHz) will provide the necessary heat penetration for a thick, robust hardened layer.

- If your primary focus is through-heating for forging or forming: A low to medium frequency is required to ensure the entire cross-section of the part reaches a uniform temperature.

By understanding the direct relationship between frequency and heat depth, you can confidently select the right process for your specific application.

Summary Table:

| Frequency Range | Heat Penetration Depth | Typical Applications |

|---|---|---|

| High (100 kHz - 500 kHz) | Shallow (thin surface layer) | Case hardening, surface hardening |

| Medium (1 kHz - 10 kHz) | Deeper (2 mm - 10 mm+) | Deep hardening of gears, shafts |

| Low (Below 1 kHz) | Deep to through-heating | Forging, through-heating of large billets |

Struggling to select the right frequency for your induction heating process? KINTEK specializes in precision lab equipment and consumables, providing tailored solutions for your laboratory's heating challenges. Our experts can help you optimize your application for efficiency and control. Contact us today to discuss your specific needs and achieve superior results with the right equipment!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Three-dimensional electromagnetic sieving instrument

- Double Plate Heating Press Mold for Lab

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?

- What role does a vacuum hot pressing furnace play in silver-diamond composites? Achieve Peak Densification and Bonding

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity