There is no single "best" material for a crucible. The optimal choice is entirely dependent on the specific material you intend to melt, its required temperature, and its chemical reactivity. Selecting the right crucible is a critical decision that balances thermal resistance with chemical compatibility to ensure a pure, uncontaminated result.

The core principle of crucible selection is not finding the material with the highest melting point, but rather matching the crucible's properties to the unique demands of the substance being melted. This prevents both catastrophic failure and subtle contamination of the final product.

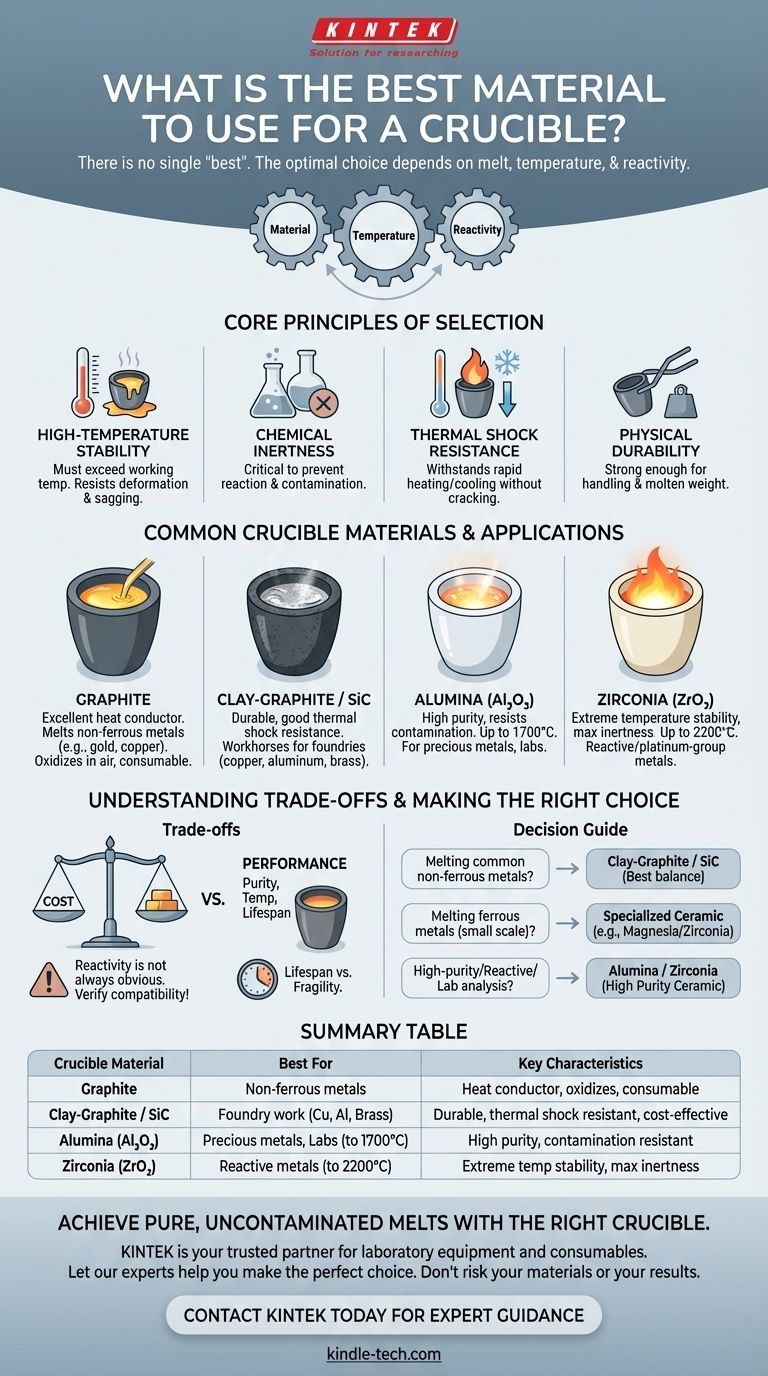

The Core Principles of Crucible Selection

To make an informed decision, you must evaluate potential materials against a few fundamental requirements. These principles dictate the success and safety of any high-temperature process.

High-Temperature Stability

A crucible’s primary function is to contain material at extreme temperatures. Its melting point must be significantly higher than the working temperature of the material it holds.

Beyond just melting, the material must also resist deformation, sagging, or degrading under prolonged thermal stress.

Chemical Inertness

This is the most critical and often overlooked characteristic. The crucible material should not react with the molten substance it contains.

Any chemical reaction can lead to two negative outcomes: it can degrade the crucible itself, causing it to fail, or it can introduce impurities from the crucible into the melt, contaminating your final product.

Thermal Shock Resistance

Crucibles are subjected to rapid temperature changes, both during heating and cooling. A material with poor thermal shock resistance will crack or shatter under these stresses.

This property is especially important in applications that involve repeated cycles of heating and cooling.

Physical Durability

The crucible must be strong enough to be handled safely with tongs and to support the weight of the molten material without breaking. While ceramics are very strong under compression, they can be brittle.

Common Crucible Materials and Their Applications

Different materials excel in different scenarios. The right choice is always a function of the job at hand.

Graphite Crucibles

Graphite is an excellent conductor of heat, which allows for efficient melting. It is a common choice for melting non-ferrous metals.

However, graphite oxidizes (burns away) in the presence of air at high temperatures, so it is often considered a consumable item with a limited lifespan. It is not suitable for melting ferrous metals like iron and steel because the carbon will dissolve into the melt.

Clay-Graphite and Silicon Carbide Crucibles

These are composite materials that enhance the properties of basic graphite. They are the workhorses of most small- to medium-sized foundries.

Clay-graphite adds durability and thermal shock resistance. Silicon carbide (SiC) offers even greater strength, durability, and resistance to oxidation, making it a superior and longer-lasting choice for melting copper, aluminum, and brass.

Ceramic Crucibles (Alumina, Zirconia)

Ceramic crucibles are used when purity is a high priority or when melting materials at extremely high temperatures.

Alumina (Al₂O₃) is a very common, high-purity ceramic suitable for temperatures up to around 1700°C (3092°F). It is excellent for melting precious metals and specialty alloys.

Zirconia (ZrO₂) is used for even more demanding applications, with a service temperature up to 2200°C (3992°F). It is often used for melting reactive metals or platinum-group metals.

Understanding the Trade-offs

Choosing a crucible involves balancing performance, lifespan, and cost. There is no perfect solution, only the best compromise for your specific goal.

Cost vs. Performance

A high-purity Zirconia crucible may offer incredible performance, but its cost is prohibitive for melting a few pounds of aluminum. Conversely, using a cheap clay-graphite crucible for a high-purity laboratory melt will ruin the sample.

You must align the investment in the crucible with the value and purity requirements of the material being melted.

Reactivity Is Not Always Obvious

A material's melting point is not a guarantee of compatibility. For example, titanium has a very high melting point, but it is also extremely reactive. Melting it in a standard Alumina crucible can cause oxygen from the ceramic to leach into the titanium, making it brittle.

Always verify the chemical compatibility between your melt and your crucible material, especially when working with reactive metals.

Lifespan and Handling

Graphite and SiC crucibles are robust but have a finite lifespan, especially in an air atmosphere. Ceramic crucibles can last a long time if handled carefully but are brittle and can be easily shattered by mechanical impact or severe thermal shock.

Making the Right Choice for Your Application

Your final decision should be guided by your primary objective.

- If your primary focus is melting common non-ferrous metals like aluminum, brass, or gold: A clay-graphite or silicon carbide crucible offers the best balance of cost, durability, and thermal performance.

- If your primary focus is melting ferrous metals like iron or steel in a small-scale operation: A specialized ceramic crucible, such as one made of magnesia or zirconia, is required to withstand the high temperatures and prevent carbon contamination.

- If your primary focus is high-purity melts, reactive metals, or laboratory analysis: A high-purity ceramic crucible like Alumina or Zirconia is the necessary choice to prevent contamination.

Ultimately, the best crucible is the one that becomes an invisible, inert container for your work.

Summary Table:

| Crucible Material | Best For | Key Characteristics |

|---|---|---|

| Graphite | Non-ferrous metals (e.g., gold, copper) | Excellent heat conductor, oxidizes in air, consumable |

| Clay-Graphite / Silicon Carbide | Copper, aluminum, brass (foundry work) | Durable, good thermal shock resistance, cost-effective |

| Alumina (Al₂O₃) | Precious metals, high-purity alloys (up to 1700°C) | High purity, resists contamination, suitable for labs |

| Zirconia (ZrO₂) | Reactive/platinum-group metals (up to 2200°C) | Extreme temperature stability, maximum chemical inertness |

Achieve Pure, Uncontaminated Melts with the Right Crucible

Selecting the correct crucible is critical to the success and safety of your high-temperature processes. Whether you are melting precious metals in a laboratory or casting non-ferrous alloys in a foundry, using the wrong material can lead to contamination, crucible failure, and ruined products.

KINTEK is your trusted partner for all laboratory equipment and consumables. We provide high-quality crucibles in a wide range of materials—including graphite, silicon carbide, alumina, and zirconia—to meet the precise demands of your application.

Let our experts help you make the perfect choice. We can guide you to the crucible that offers the ideal balance of thermal stability, chemical resistance, and cost-effectiveness for your specific needs.

Don't risk your materials or your results. Contact KINTEK today to discuss your requirements and ensure you have the right tool for the job.

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- How does the choice between graphite and metal-lined crucibles affect molten salt corrosion? Find the Right Research Tool

- What are crucibles for laboratory use? Essential Guide to High-Temperature Containment

- Why are high-temperature crucibles necessary for LAGP synthesis? Ensure Purity in Glass-Ceramic Electrolyte Production

- What is a crucible furnace used for melting of? Melt Non-Ferrous Metals from Aluminum to Gold

- Why are high-purity graphite crucibles preferred for sulfide solid electrolytes? Achieve Superior Material Purity

- What is a crucible furnace in casting process? A Guide to Small-Batch, Versatile Melting

- What role does a nickel crucible play in iridium powder fusion? Ensure High-Temperature Chemical Resistance

- What are the pros and cons of a crucible furnace? Maximize Versatility for Small-Scale Melting