At its core, an electric arc is caused by a voltage difference that is strong enough to overcome the insulating properties of a medium like air. This process, known as dielectric breakdown, transforms the insulator into a conductor by stripping electrons from its atoms. The result is a sustained, high-temperature plasma channel that allows electrical current to flow where it normally shouldn't.

The fundamental cause of an arc is an electrical potential sufficient to ionize a non-conductive medium, creating a sustained plasma discharge that acts as a pathway for current. It is essentially electricity forcing its way through an insulator.

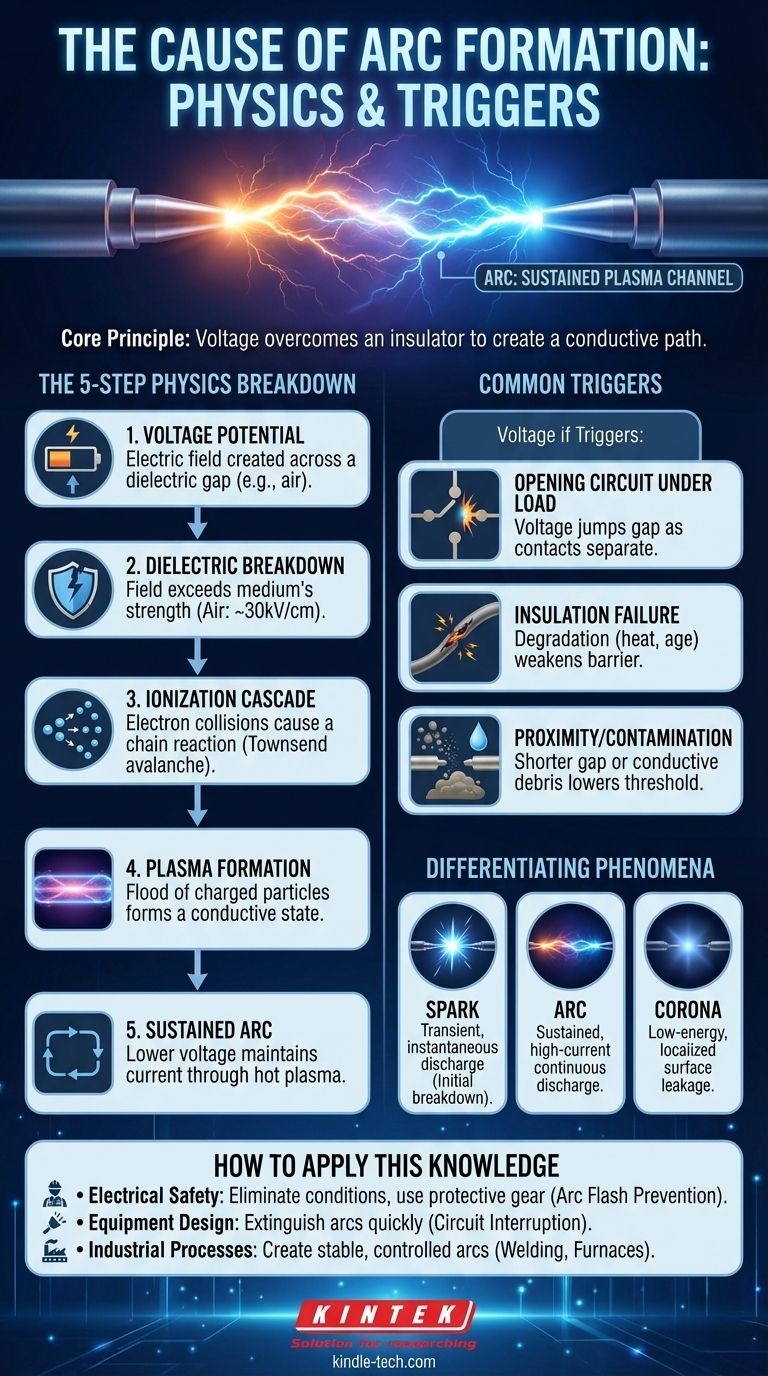

The Physics of Arc Formation: A Step-by-Step Breakdown

To truly understand an arc, we must look at the sequence of events that turns an insulator like air into a superheated conductor. This process happens in a fraction of a second.

The Initial Condition: Voltage Potential

Everything begins with a voltage difference between two conductive points separated by an insulating medium (a dielectric), most commonly air. This creates an electric field in the gap between them.

Dielectric Breakdown: The Tipping Point

Every insulator has a dielectric strength—a maximum electric field it can withstand before it breaks down. For dry air at sea level, this is about 30,000 volts per centimeter.

When the voltage across the gap is high enough, the electric field exceeds this strength, and the breakdown process begins.

Ionization Cascade: The Chain Reaction

The air contains a small number of naturally occurring free electrons. The strong electric field accelerates these electrons to very high speeds.

These high-energy electrons collide with neutral gas atoms, knocking additional electrons loose. This process repeats exponentially in a chain reaction known as a Townsend avalanche, rapidly creating a massive number of free electrons and positive ions.

Plasma Formation: The Conductive Channel

This flood of charged particles—ions and electrons—forms plasma, a state of matter that is highly electrically conductive.

This plasma channel bridges the gap between the conductors, creating a low-resistance path. This visible, intensely hot, and bright channel is what we perceive as the arc.

Sustaining the Arc

Once the plasma channel is established, a much lower voltage is required to sustain the current flow compared to the voltage needed to initiate it. The high temperature of the plasma maintains the ionization, keeping the path conductive until the current is interrupted or the voltage drops too low.

Common Triggers for Arc Formation

While the underlying physics is consistent, several real-world events can create the conditions necessary for an arc to form, often at voltages much lower than the theoretical breakdown strength of air.

Opening a Circuit Under Load

This is the most common cause. When a switch or circuit breaker opens, the contacts separate. The voltage can easily jump the tiny initial air gap, heating and ionizing the air to draw an arc that can persist as the contacts move further apart.

Insulation Failure

Over time, electrical insulation can degrade due to heat, age, moisture, or chemical exposure. This weakened insulation can no longer withstand the normal operating voltage, leading to a sudden breakdown and arc fault.

Proximity or Contamination

Reducing the distance between conductors shortens the gap the voltage needs to jump. Similarly, contaminants like dust, oil, or moisture on the surface of an insulator can create a conductive path, dramatically lowering the breakdown voltage.

Differentiating Arc, Spark, and Corona

These terms are often used interchangeably, but they describe distinct phenomena. Understanding the difference is critical for proper diagnosis.

Spark: The Transient Event

A spark is an instantaneous and temporary electrical discharge. It's the initial breakdown event, like the static shock you get from a doorknob. A spark may initiate an arc, but it is not a sustained current flow.

Arc: The Sustained Discharge

An arc is a continuous, high-current discharge that is sustained over a period of time. It requires a power source capable of supplying enough current to keep the plasma channel ionized and hot. All arcs begin with a spark, but not all sparks become arcs.

Corona: The Low-Energy Leakage

A corona discharge is a localized breakdown of air directly at the surface of a high-voltage conductor, often at sharp points. It appears as a faint bluish glow but does not fully bridge the gap to another conductor. It represents a low-level leakage of current into the air.

How to Apply This Knowledge

Understanding the cause of an arc is the first step toward either preventing it for safety or controlling it for industrial applications. Your approach depends entirely on your objective.

- If your primary focus is electrical safety (Arc Flash Prevention): Your goal is to eliminate the conditions for an arc by de-energizing equipment, increasing working distance, and using correctly rated protective gear to survive an incident.

- If your primary focus is equipment design (Circuit Interruption): Your goal is to extinguish the arc as quickly as possible using methods like high-speed contact separation, magnetic "blowout" coils, or blasts of compressed air or insulating gas (SF6).

- If your primary focus is an industrial process (like Welding or Arc Furnaces): Your goal is to create and sustain a stable, controlled arc by precisely managing voltage, current, and the physical gap to generate predictable heat.

Mastering the principles of arc formation allows you to manage one of the most powerful and potentially dangerous phenomena in electrical engineering.

Summary Table:

| Event | Description | Key Factor |

|---|---|---|

| Voltage Potential | A voltage difference creates an electric field across a gap. | High Voltage |

| Dielectric Breakdown | The electric field exceeds the insulator's strength (e.g., 30 kV/cm for air). | Exceeds Dielectric Strength |

| Ionization Cascade | Free electrons collide with atoms, creating more electrons in a chain reaction. | Townsend Avalanche |

| Plasma Formation | A conductive channel of ionized gas (plasma) bridges the gap. | High-Temperature Plasma |

| Sustained Arc | A lower voltage maintains the current flow through the hot plasma. | Continuous Current Supply |

Master Arc Control with KINTEK

Whether your goal is enhancing electrical safety in your facility, improving circuit breaker design, or achieving precise industrial heating and welding, understanding and managing electric arcs is critical. KINTEK specializes in advanced lab equipment and consumables that support research and development in electrical engineering, materials science, and plasma processes.

Let us help you harness this powerful phenomenon safely and effectively. Contact our experts today to discuss your specific application needs and discover the right solutions for your laboratory.

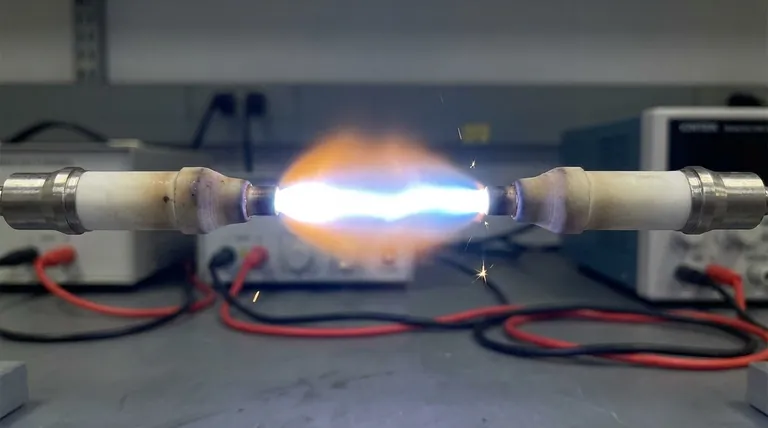

Visual Guide

Related Products

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

- Spark Plasma Sintering Furnace SPS Furnace

- Automatic Laboratory Heat Press Machine

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- How do you maintain vacuum pressure? Master the balance between gas removal and gas load for stable performance.

- What are the critical functions of Polytetrafluoroethylene (PTFE) gaskets within a glow discharge unit? Enhance Precision

- What is the importance of leakage in a vacuum system? Prevent Contamination and Process Failure

- How thick is the thin film deposition? A Guide to Ranging from Nanometers to Micrometers

- What instrument is used to measure vacuum? Selecting the Right Gauge for Your Pressure Range