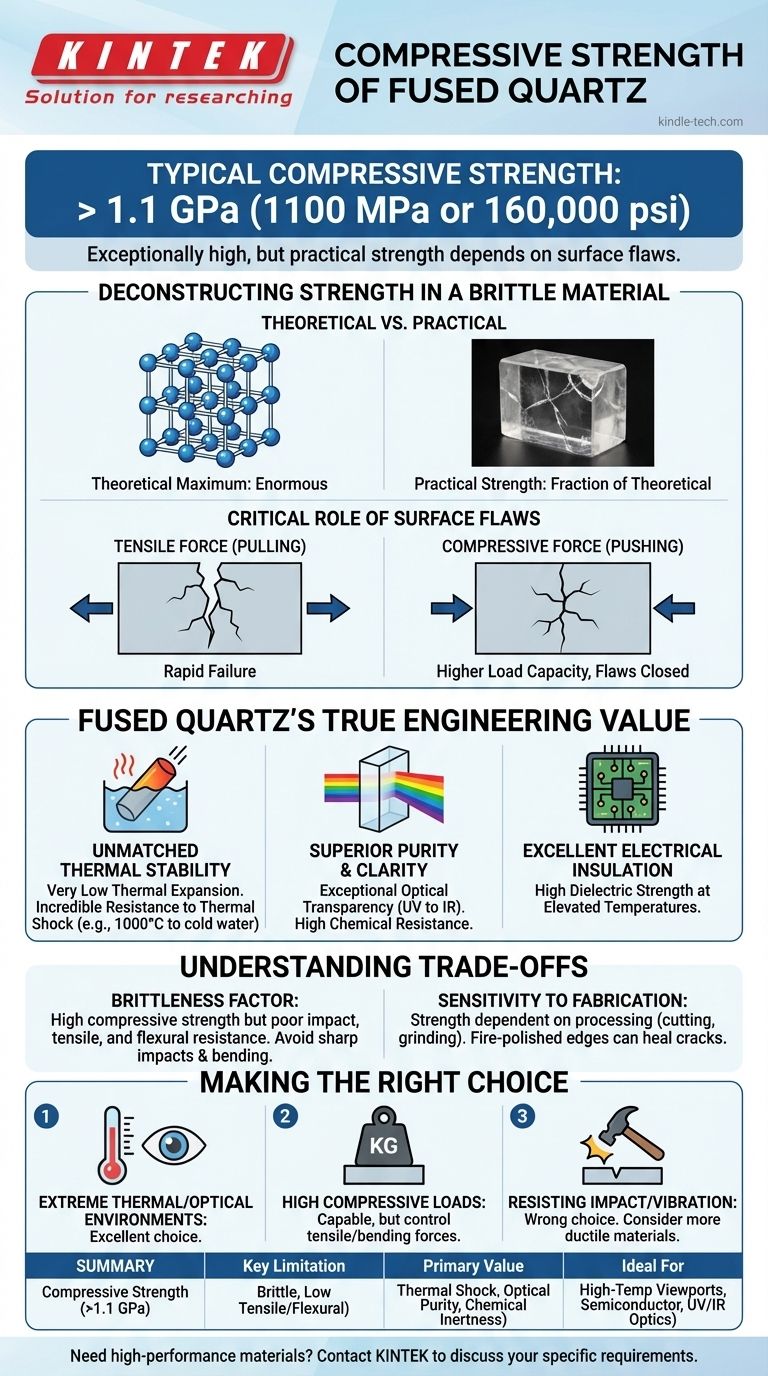

In short, the compressive strength of fused quartz is exceptionally high, typically exceeding 1.1 GPa (1100 MPa or 160,000 psi). However, this single value does not tell the whole story, as the practical strength of a fused quartz component is ultimately determined by its surface condition and the presence of microscopic flaws.

Fused quartz is rarely selected for its compressive strength alone. Its true value lies in an unparalleled combination of thermal stability, optical purity, and chemical inertness, which makes it indispensable for applications where other materials would fail, despite its brittle nature.

Deconstructing Strength in a Brittle Material

Engineers and scientists value fused quartz for its performance under extreme conditions. While its compressive strength is impressive on paper, understanding the context of that strength is critical for successful application design.

Theoretical vs. Practical Strength

The strength of a material is dictated by the atomic bonds holding it together. Based on these bonds, the theoretical compressive strength of pure silica (SiO₂) is enormous.

However, in the real world, no material is perfect. The usable strength of a fused quartz component is always a fraction of this theoretical maximum.

The Critical Role of Surface Flaws

Fused quartz is an amorphous (non-crystalline) ceramic. Like other glasses, it is a brittle material.

This means its failure is governed by the propagation of microscopic cracks, often called Griffith flaws, which are inevitably present on the surface. When a tensile (pulling) force is applied, these tiny flaws concentrate stress at their tips and can rapidly grow, leading to sudden, catastrophic failure.

Why Compressive Strength Is So High

Under a compressive (pushing) load, the physics are different. The compressive force pushes the surfaces of these microscopic cracks together, effectively closing them.

By preventing these inherent flaws from propagating, the material can withstand a much higher load before it fails. This is why all brittle materials, from concrete to ceramics and glass, are vastly stronger in compression than they are in tension.

Fused Quartz's True Engineering Value

While mechanically robust under compression, the primary reasons for choosing fused quartz are nearly always related to its other unique properties, which allow it to function where other glasses cannot.

Unmatched Thermal Stability

Fused quartz has a very low coefficient of thermal expansion. It barely changes size with temperature, which gives it incredible resistance to thermal shock. You can heat it to over 1000°C and plunge it into cold water without it cracking.

Superior Purity and Clarity

Its manufacturing process results in extremely high chemical purity. This ensures two things: exceptional optical transparency from the deep ultraviolet to the infrared spectrum and high resistance to chemical attack.

Excellent Electrical Insulation

Fused quartz is one of the best electrical insulators known, maintaining its high dielectric strength even at elevated temperatures. This makes it a critical material in the semiconductor industry and for high-performance electronics.

Understanding the Trade-offs

No material is perfect. The key to successful design is acknowledging a material's limitations and designing around them.

The Brittleness Factor

The most significant trade-off for fused quartz is its brittleness. Despite its high compressive strength, it has poor resistance to impact and very low tensile and flexural strength (strength against bending). Any design must carefully avoid exposing the component to sharp impacts, bending forces, or tensile loads.

Sensitivity to Fabrication

The final strength of a part is highly dependent on its processing. Cutting, grinding, and even handling can introduce new surface flaws that weaken the component. This is why specifications often call for features like fire-polished edges, which can heal microscopic cracks and improve overall strength.

Making the Right Choice for Your Application

Use this framework to decide if fused quartz is the correct material for your project.

- If your primary focus is performance in extreme thermal or optical environments: Fused quartz is an exceptional choice, purpose-built for stability under heat and for high-purity light transmission.

- If your primary focus is withstanding high compressive loads: Fused quartz is highly capable, but your design must rigorously control for any tensile or bending forces and protect against impact.

- If your primary focus is resisting impact, vibration, or bending: Fused quartz is likely the wrong choice. You should consider more ductile materials or tougher ceramics like alumina or zirconia.

Choosing the right material requires understanding its complete profile, not just a single data point.

Summary Table:

| Property | Value / Key Characteristic |

|---|---|

| Compressive Strength | > 1.1 GPa (160,000 psi) |

| Key Limitation | Brittle; low tensile/flexural strength |

| Primary Value | Extreme thermal shock resistance, high optical purity, chemical inertness |

| Ideal For | High-temperature viewports, semiconductor components, UV/IR optics, corrosive environments |

Need a material that performs under extreme conditions? Fused quartz from KINTEK offers unparalleled thermal stability, optical clarity, and chemical purity for your most demanding laboratory and industrial applications. Our experts can help you determine if it's the right solution for your project's unique challenges. Contact our team today to discuss your specific requirements and explore how KINTEK's high-performance lab materials can drive your success.

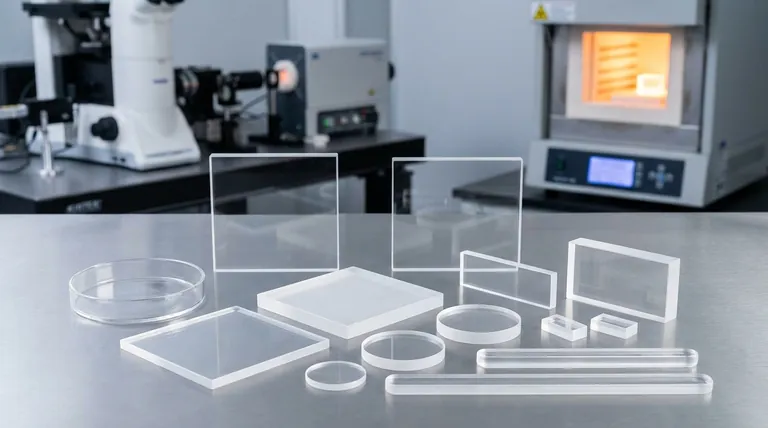

Visual Guide

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Zinc Selenide ZnSe Optical Window Glass Substrate Wafer and Lens

- CF Ultra-High Vacuum Observation Window Window Flange High Borosilicate Glass Sight Glass

People Also Ask

- Does quartz have a high melting point? Discover Its Superior High-Temperature Performance

- What is optical quartz? The Ultimate Material for UV and High-Temp Optics

- What is the working temperature of quartz glass? Master Its High-Temp Limits & Applications

- How does quartz differ from glass? A Guide to Material Selection for Performance

- What temperature does quartz glass melt at? Understanding Its Softening Point and Practical Limits