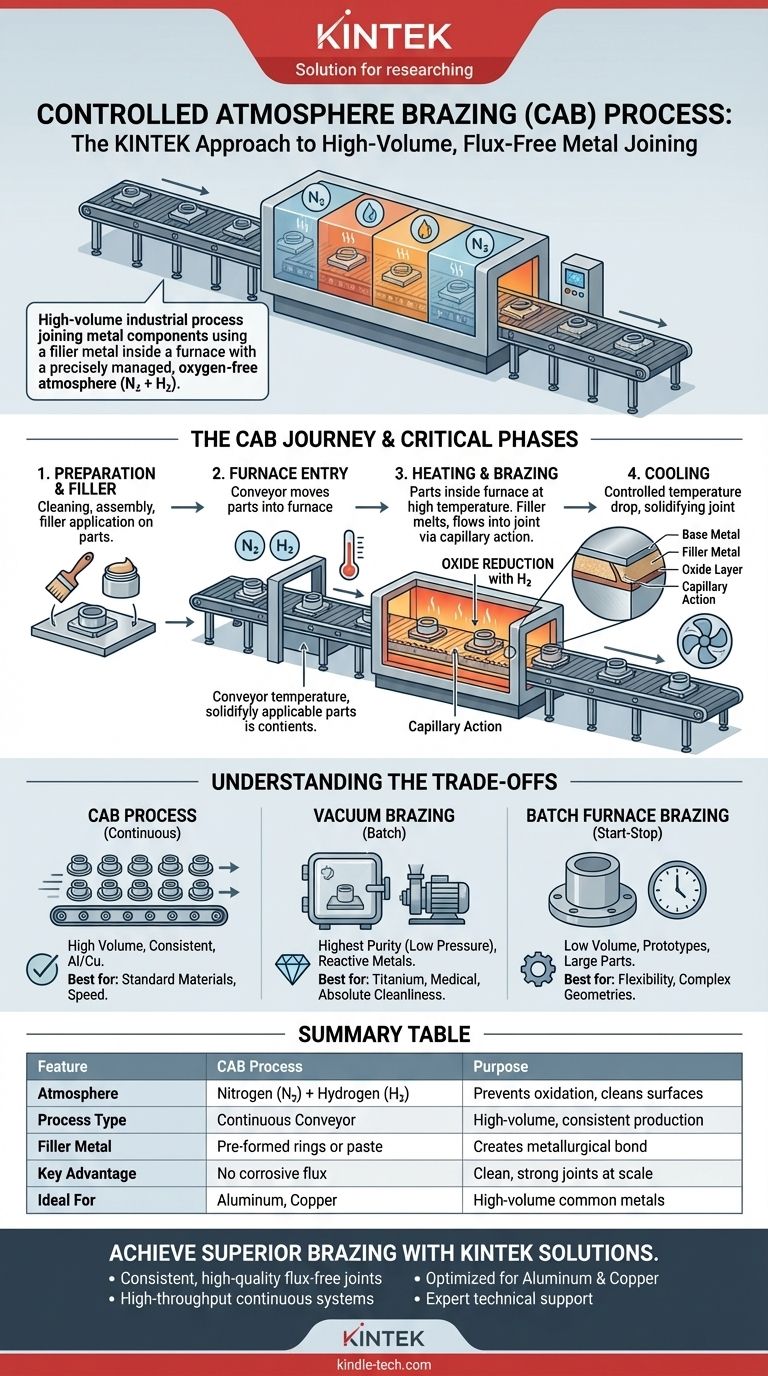

In short, Controlled Atmosphere Brazing (CAB) is a high-volume industrial process that joins metal components using a filler metal inside a furnace with a precisely managed, oxygen-free atmosphere. Parts move continuously on a conveyor belt through different heating and cooling zones, allowing for consistent, clean, and strong joints without the use of corrosive fluxes in many cases. This controlled environment prevents oxidation, which is the primary cause of weak or failed brazed joints.

The core principle of Controlled Atmosphere Brazing is not just about heating parts, but about creating a chemically ideal environment. By replacing oxygen with specific gases like nitrogen and hydrogen, the process ensures that the filler metal can flow cleanly and bond perfectly with the parent metals, resulting in superior joint integrity at an industrial scale.

How the CAB Process Works

To truly understand CAB, it's best to view it as a meticulously choreographed journey that each component takes. The furnace's atmosphere is the most critical element, dictating the quality of the final bond.

The Purpose of a Controlled Atmosphere

The primary goal is to prevent the formation of oxides on the surface of the metal parts as they are heated. Oxides act as a barrier, preventing the molten filler metal from properly wetting and bonding to the parent materials.

The atmosphere typically consists of oxygen-free nitrogen (N2), which is an inert gas used to displace all the air and oxygen from the furnace.

In some cases, a small percentage of hydrogen (H2) is added. Hydrogen acts as an active agent, chemically reducing any light surface oxides that may already be present on the parts, further cleaning them for a perfect braze.

A Step-by-Step Journey Through the Furnace

The CAB process is a continuous flow, ensuring high throughput and consistency.

- Preparation: Parts are cleaned and degreased. They are then assembled, often with a press fit or small tack weld to hold them in place.

- Filler Application: A filler metal, either as a pre-formed ring or a paste, is applied to the joint area.

- Furnace Entry: The assembled parts enter the furnace on a conveyor belt. The furnace is divided into several distinct zones.

- Heating and Brazing: The parts are heated to the specific brazing temperature. At this point, the filler metal melts and is drawn into the joint by capillary action.

- Cooling: The newly brazed parts move into a cooling zone, where the temperature is brought down in a controlled manner, still within the protective atmosphere, to solidify the joint without introducing thermal stress or oxidation.

The Critical Phases of the Joint Formation

Inside the furnace, a precise sequence of events occurs at the microscopic level. Using aluminum as an example:

- Initial Heating (below 565°C): The base metal, filler metal, and any flux (if used) are all in solid form. Differential thermal expansion begins to create micro-cracks in the tough, natural aluminum oxide layer.

- Flux Activation / Oxide Reduction (around 570°C): If a flux is used, it melts and chemically breaks down the remaining oxide layer. If no flux is used, the hydrogen in the atmosphere performs this cleaning function.

- Filler Metal Flow (around 580-600°C): The filler metal melts. Now that the parent metal is clean, the molten filler flows freely and is pulled into the gap, creating the metallurgical bond.

Understanding the Trade-offs: CAB vs. Other Methods

Controlled Atmosphere Brazing is not the only method for furnace brazing. Understanding its advantages and disadvantages compared to other processes is key to making an informed decision.

CAB vs. Batch Furnace Brazing

The primary difference is throughput. CAB uses a continuous conveyor belt, making it ideal for maintaining high-volume production with thousands of identical parts.

Batch brazing, by contrast, involves loading a set of parts into a furnace, sealing it, running the heat cycle, cooling, and then unloading. This start-stop process is inherently slower and better suited for smaller production runs, prototypes, or parts with very large or complex geometries.

CAB vs. Vacuum Brazing

This comparison is about the purity of the atmosphere. While CAB uses a controlled gas environment, vacuum brazing creates a low-pressure vacuum (around 10⁻⁵ Torr) to remove virtually all gases.

Vacuum brazing is a fluxless process that provides the absolute cleanest environment, making it essential for joining highly reactive metals like titanium or medical-grade stainless steel. However, it is typically a batch process and is significantly more expensive and time-consuming than CAB.

Making the Right Choice for Your Goal

Selecting the correct brazing process is a critical engineering decision that directly impacts cost, quality, and production speed. Your choice should be dictated by your specific application requirements.

- If your primary focus is high-volume production of common materials (like aluminum or copper): CAB is the industry standard for its excellent balance of quality, speed, and cost-effectiveness.

- If your primary focus is joining highly reactive metals or achieving the absolute highest purity joint: Vacuum brazing is the superior, albeit slower and more expensive, choice.

- If your primary focus is low-volume runs, prototyping, or handling very large parts: The slower, more flexible batch furnace process may be a more practical and economical option.

Ultimately, selecting the correct process hinges on a clear understanding of your material, production volume, and quality requirements.

Summary Table:

| Feature | CAB Process | Purpose |

|---|---|---|

| Atmosphere | Nitrogen (N₂) + Hydrogen (H₂) | Prevents oxidation, cleans metal surfaces |

| Process Type | Continuous conveyor belt | High-volume, consistent production |

| Filler Metal | Pre-formed rings or paste | Creates metallurgical bond via capillary action |

| Key Advantage | No corrosive flux required | Clean, strong joints at industrial scale |

| Ideal For | Aluminum, copper components | High-volume production of common metals |

Need reliable brazing solutions for your laboratory or production line?

At KINTEK, we specialize in advanced thermal processing equipment, including Controlled Atmosphere Brazing systems designed for precision and efficiency. Our expertise in lab equipment and consumables ensures you get the right solution for your specific metal joining challenges.

We help you achieve:

- Consistent, high-quality brazed joints without flux corrosion

- High-throughput production with continuous conveyor systems

- Optimized processes for materials like aluminum and copper

- Technical support from industry experts

Ready to enhance your brazing capabilities? Contact our team today to discuss how KINTEK's brazing solutions can improve your manufacturing outcomes.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- How does an atmosphere furnace facilitate the post-treatment of nickel-plated carbon fibers? Ensure Peak Bonding

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- What is an example of an inert atmosphere? Discover the Best Gas for Your Process

- How do you make an inert atmosphere? Master Safe, Pure Processes with Inerting