The cost of a biomass pellet project involves significant investment and operational expenses.

The total investment costs for installation, fume gas purifier, and infrastructure amount to €1,450,000.

Operational costs per year are €961,000, but these can be offset by profits from the sale of produced heat, energy, and bio-oils, which in the example provided amount to €1.8 million.

7 Key Factors to Consider

1. Investment Costs

Installation: The initial cost for setting up the biomass pellet production facility is €1,000,000. This includes the cost of machinery, equipment, and the physical structure of the plant.

Fume Gas Purifier: An additional €250,000 is required for the installation of a fume gas purifier. This equipment is crucial for environmental compliance and safety, ensuring that emissions meet regulatory standards.

Infrastructure: The infrastructure costs, which include necessary site improvements and support systems, amount to €200,000.

2. Operational Costs

The annual operational costs are €961,000. These costs cover expenses such as labor, maintenance, utilities, and raw materials.

However, the profitability of the project can be significantly influenced by the revenue generated from the sale of heat, energy, and bio-oils. In the example given, these sales can potentially offset the operational costs, resulting in a net profit.

3. Profitability and Economic Viability

The economic viability of a biomass pellet project depends on several factors including the cost of feedstock, the selling price of the end products, and the availability of local support and incentives.

The project can be economically attractive if the feedstock is low-cost and the products can be sold at a high price.

Additionally, the regulatory and legal framework in the region can significantly impact the feasibility and profitability of the project.

4. Environmental Impact and Sustainability

Biomass pyrolysis can produce environmentally friendly products like biochar, bio-oil, and syngas, which can be used as renewable energy sources.

This process can help reduce dependence on fossil fuels and contribute to environmental sustainability.

However, the environmental impact varies based on the type of biomass used and the technology employed.

5. Starting a Biomass Pellet Production Line

To start a biomass pellet production line, one must ensure the availability of sufficient raw materials such as wood, sawdust, and other organic materials.

Understanding the characteristics of these materials, including their shape, size, and moisture content, is crucial for setting up an effective pelletizing plan.

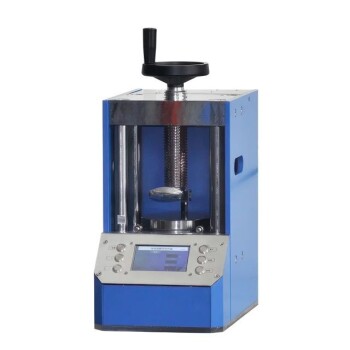

The choice of equipment, such as a flat die pellet mill, is also important for converting biomass into pellets efficiently.

6. Regulatory and Legal Framework

The regulatory and legal framework in the region can significantly impact the feasibility and profitability of the project.

Ensuring compliance with local regulations can help avoid costly penalties and ensure the smooth operation of the biomass pellet project.

7. Strategic Sales and Marketing

Strategic sales and marketing can help maximize the revenue generated from the sale of heat, energy, and bio-oils.

Identifying potential markets and establishing strong distribution channels can enhance the profitability of the biomass pellet project.

Continue exploring, consult our experts

Embark on a sustainable and profitable future with KINTEK SOLUTION. Discover how our advanced biomass pellet production solutions can optimize your investment and operational costs, making your biomass project more economically viable and environmentally friendly.

Trust us to supply the high-quality equipment and expertise needed to transform raw materials into valuable biomass pellets. Take the first step towards a greener tomorrow – contact us today for a custom-tailored solution that fits your unique needs.