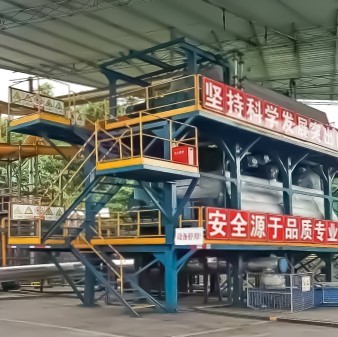

Electric Rotary Kiln

Sludge treatment pyrolysis plant

Item Number : KSTE

Price varies based on specs and customizations

- Host volume

- 31.8-49.2 cubic meters

- Daily throughput

- 9-20 ton

- Operating power

- 20-30 kW/h

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Introductions

The Sludge Treatment Pyrolysis Plant is a new type of technical method commonly used in the harmless treatment of oil sludge. It can effectively recover the oil resources in the oil sludge, and it is not easy to produce secondary pollutants, so that Realize the recycling of oil sludge and the recycling of waste. The final pyrolysis temperature of oil sludge is 550°C, and the oil yield is about 15-50% depending on the type of oil sludge. The chemical composition of the obtained pyrolysis oil is similar to that of diesel oil and can be recycled use.

Applications

Pyrolysis technology is widely used in the treatment of oil sludge. It is a new type of technical method commonly used in the harmless treatment of oil sludge. It can effectively recover the oil resources in the oil sludge, and it is not easy to produce secondary pollutants, so that Realize the recycling of oil sludge and the recycling of waste. The final pyrolysis temperature of oil sludge is 550°C, and the oil yield is about 15-50% depending on the type of oil sludge. The chemical composition of the obtained pyrolysis oil is similar to that of diesel oil and can be recycled use. The oil sludge pyrolysis equipment produced by our company has overcome the previous technical difficulties of oil sludge sticking to the wall.

In addition, the equipment is equipped with a tail gas combustion and reuse device, which is environmentally friendly and saves fuel. And ensure that there is no discharge of three wastes. The equipment takes natural gas as fuel as an example (pyrolysis oil can also be used), the equipment is equipped with a dust collector, the gas discharge is guaranteed to meet the standard, the entire cooling system circulates water, and no waste water is discharged. In terms of product quality and value, the pyrolysis equipment is a good solution. The problem of garbage pollution will not cause secondary pollution, and it will also create huge economic benefits while solving the problem.

The main application areas of this product are:

- Oil sludge treatment

- Waste oil treatment

- Waste plastic treatment

- Waste rubber treatment

- Waste tire treatment

- Medical waste treatment

System composition and process principle

The system takes the heating host as the core, including the host system smoke and dust purification system, cooling system, oil collection system, and combustible waste gas recovery system.

- Firstly, the sludge to be processed is transported to the inside of the main engine through a shaftless screw conveyor or a pump body (depending on the flow state of the sludge), and the furnace door is sealed. With the heating of the furnace, the sludge is gradually decomposed inside the main engine. In view of the sludge has High viscosity, easy to coke and stick to the wall, the main engine is designed with an anti-coking device, which uses the sliding friction of the inner wall structure of the scraper to solve the problem of sticking to the wall, preventing the equipment from manually cleaning coke every few days.

- After the petroleum hydrocarbon components in the oil sludge are decomposed by pyrolysis, high-temperature steam is formed and enters the gas distribution drum, and part of the heavy oil components and mechanical impurities are decondensed, and then enter the cooling system. Inside, the combustible waste gas generated in this process that cannot be liquefied under normal temperature and pressure is recycled to the furnace through the combustible waste gas recovery system, and is supplied to the main engine for heating.

- The soot generated during the combustion process is processed by the soot treatment system. The soot treatment system includes alkaline water, high-pressure atomizing nozzles, and Ball magnetic rings and other materials. The gas that meets the standard is discharged through the smoke pipe to meet the environmental protection emission standard.

- Through high-temperature pyrolysis in a closed environment, the effective oil in the sludge is separated and recycled. Then, under a high-temperature and oxygen-free environment, the oil content of the residue is controlled below 3‰ (actually 63ppm), which fully meets the environmental protection requirements.

Process flow

| Step 1: Feeding | According to the cause of sludge or the state of existence, liquid or solid-liquid mixed sludge can be injected into the heating host using a suction pump, and solid can be injected into the heating host using a shaftless screw feeder , close the loading door after loading. | |

| Step 2: Heating | Use natural gas and non-condensable gas to heat the reactor evenly, and the temperature will gradually rise to about 260 degrees after heating for about 2 hours. The oil goes into the intermediate tank. | |

| Step 3: Non-condensable gas treatment | Non-condensable gas (C1-C4 components) flows into the oil tank together with the oil, and this part of non-condensable gas passes through 2 water-sealed fire arresting devices and 1 fire arresting device Finally, it goes into the furnace and is fully burned by the burner, which can also save a large part of fuel. | |

| Step 4: Smoke and dust treatment | All the smoke and dust produced by combustion are pumped into the general dust removal system by a special induced draft fan for treatment. The treated smoke and dust are white water vapor without black particles, and then the water vapor will enter industrial purification The device carries out standard emission treatment to ensure that the emitted smoke and dust emissions meet the emission standards required by Huanbai. | |

| Step 5: Slag discharge | After the temperature of the reaction kettle drops below 80 degrees, open the slag discharge door, connect the automatic slag discharge machine to start slag discharge, and the discharged slag is transported to the slag storage bin by the negative pressure air conveying equipment through the pipeline , to ensure that the slag discharge process is dust-free. | |

Reference process flow chart

Features

- High oil yield: The oil yield of the pyrolysis equipment is about 15-50% depending on the type of oil sludge.

- Environmentally friendly: The equipment is equipped with a tail gas combustion and reuse device, which is environmentally friendly and saves fuel.

- No secondary pollution: The equipment ensures that there is no discharge of three wastes.

- Easy to operate: The equipment is easy to operate and maintain.

- Cost-effective: The equipment is cost-effective and can help you save money in the long run.

Technical Parameters

| Model | Host volume | Daily throughput | total operating power |

| 2600*6000 | 31.8 cubic meters | 9-10 tons | 20 kW/h |

| 2600*6600 | 35 cubic meters | 10-12 tons | 20 kW/h |

| 2800*6600 | 40.6 cubic meters | 12-14 tons | 20 kW/h |

| 2800*7500 | 46.2 cubic meters | 15-18 tons | 26 kW/h |

| 2800*8000 | 49.2 cubic meters | 18-20 tons | 30 kW/h |

Advantages

- Integrated design, compact structure, complete integrity and guaranteed safety. The main body of the equipment adopts the standard Q345R special boiler steel plate (high temperature and oxidation resistant alloy steel) resistant to oxidation, corrosion, long life and safety.

- The equipment adopts a special anti-coking structure, which greatly solves the current situation that the sludge is coked and inconvenient to clean during the pyrolysis process.

- The main engine adopts the outer ring gear to rotate. In addition, the ring gear is formed once, which is strong and durable. It is more stable than the pin-pin sleeve transmission on the market. In case of damage, protect the host motor and reducer and prolong its service life.

- The welding of the main engine is (automatic submerged arc machine welding), and the welding is formed once, even and full.

- The cooling system includes: cooling pipes, air distribution bag, cooling pool, etc. It has the characteristics of large cooling area, good cooling effect and high oil collection rate.

- The waste residue after pyrolysis can meet the emission standard required by environmental protection the oil content of 2%.

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

FAQ

What is a pyrolysis plant?

What is a pyrolysis furnace?

How does a pyrolysis plant work?

How does a pyrolysis furnace work?

What are the main applications of pyrolysis plants?

What are the applications of pyrolysis furnaces?

What are the advantages of using pyrolysis furnaces?

What factors should be considered when selecting a pyrolysis furnace?

What safety precautions should be followed when using a pyrolysis furnace?

4.7

out of

5

This plant is a game changer in sludge management. It reduces waste and creates a valuable resource from what was once a liability.

4.9

out of

5

Investing in this plant was one of the best decisions we've made. The efficiency and cost-effectiveness are remarkable, resulting in significant profits.

4.8

out of

5

The plant's technological advancements are impressive. It minimizes emissions and ensures environmental compliance, making it a sustainable solution for sludge treatment.

4.7

out of

5

The quality of the oil produced by this plant is excellent. It meets industry standards and can be directly sold or further refined for higher returns.

4.9

out of

5

The plant's durability is exceptional. It withstands demanding conditions and operates seamlessly, ensuring long-term performance and reliability.

4.8

out of

5

The speed of delivery was commendable. The plant arrived promptly, allowing us to commence operations without delay.

4.7

out of

5

The plant's value for money is unbeatable. Its efficiency and profitability make it a worthwhile investment with a rapid return on investment.

4.9

out of

5

The customer service provided by KINTEK SOLUTION is outstanding. They are always responsive, knowledgeable, and go above and beyond to ensure customer satisfaction.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

The waste tire refining pyrolysis plant produced by our company adopts a new type of pyrolysis technology, which makes tires heated under the condition of complete anoxic or limited oxygen supply so that high molecular polymers and organic additives are degraded into low molecular or small molecules compounds, thereby recovering tire oil.

This device is heated by a horizontal rotary heating furnace, which can be used for continuous production and processing capacity; 20-30 tons/day can process tire oil to produce diesel and by-products.

rotary biomass pyrolysis furnace plant

Learn about Rotary Biomass Pyrolysis Furnaces & how they decompose organic material at high temps without oxygen. Use for biofuels, waste processing, chemicals & more.

Continuous working electric heating pyrolysis furnace plant

Efficiently calcine and dry bulk powder and lump fluid materials with an electric heating rotary furnace. Ideal for processing lithium ion battery materials and more.

Electric rotary kiln pyrolysis furnace plant pyrolysis machine electric rotary calciner

Electric rotary kiln - precisely controlled, it's ideal for calcination and drying of materials like lithium cobalate, rare earths, and non-ferrous metals.

Spark plasma sintering furnace SPS furnace

Discover the benefits of Spark Plasma Sintering Furnaces for rapid, low-temperature material preparation. Uniform heating, low cost & eco-friendly.

Slide PECVD tube furnace with liquid gasifier PECVD machine

KT-PE12 Slide PECVD System: Wide power range, programmable temp control, fast heating/cooling with sliding system, MFC mass flow control & vacuum pump.

Bottom discharge graphitization furnace for carbon materials

Bottom-out graphitization furnace for carbon materials, ultra-high temperature furnace up to 3100°C, suitable for graphitization and sintering of carbon rods and carbon blocks. Vertical design, bottom discharging, convenient feeding and discharging, high temperature uniformity, low energy consumption, good stability, hydraulic lifting system, convenient loading and unloading.

Hydrothermal Synthesis Reactor

Discover the applications of Hydrothermal Synthesis Reactor - a small, corrosion-resistant reactor for chemical labs. Achieve rapid digestion of insoluble substances in a safe and reliable way. Learn more now.

Electric activated carbon regeneration furnace

Revitalize your activated carbon with KinTek's Electric Regeneration Furnace. Achieve efficient and cost-effective regeneration with our highly automated rotary kiln and intelligent thermal controller.

Negative Material Graphitization Furnace

Graphitization furnace for battery production has uniform temperature and low energy consumption. Graphitization furnace for negative electrode materials: an efficient graphitization solution for battery production and advanced functions to enhance battery performance.

PTFE bottle oil fume sampling tube

PTFE products are generally called "non-stick coating", which is a synthetic polymer material that replaces all hydrogen atoms in polyethylene with fluorine.

Large Vertical Graphitization Furnace

A large vertical high-temperature graphitization furnace is a type of industrial furnace used for the graphitization of carbon materials, such as carbon fiber and carbon black. It is a high-temperature furnace that can reach temperatures of up to 3100°C.

Explosive Proof Hydrothermal Synthesis Reactor

Enhance your lab reactions with Explosive Proof Hydrothermal Synthesis Reactor. Corrosion-resistant, safe, and reliable. Order now for faster analysis!

Split multi heating zone rotary tube furnace

Multi zone rotary furnace for high-precision temperature control with 2-8 independent heating zones. Ideal for lithium ion battery electrode materials and high-temperature reactions. Can work under vacuum and controlled atmosphere.

Continuous graphitization furnace

High-temperature graphitization furnace is a professional equipment for graphitization treatment of carbon materials. It is a key equipment for the production of high-quality graphite products. It has high temperature, high efficiency and uniform heating. It is suitable for various high-temperature treatments and graphitization treatments. It is widely used in metallurgy, electronics, aerospace, etc. industry.

High Thermal Conductivity Film Graphitization Furnace

The high thermal conductivity film graphitization furnace has uniform temperature, low energy consumption and can operate continuously.

Purify and concentrate natural products with ease using our molecular distillation process. With high vacuum pressure, low operating temperatures, and short heating times, preserve the natural quality of your materials while achieving excellent separation. Discover the advantages today!

Inclined rotary plasma enhanced chemical deposition (PECVD) tube furnace machine

Introducing our inclined rotary PECVD furnace for precise thin film deposition. Enjoy automatic matching source, PID programmable temperature control, and high accuracy MFC mass flowmeter control. Built-in safety features for peace of mind.

Efficiently separate low-boiling solvents with the 5-50L Rotary Evaporator. Ideal for chemical labs, it offers precise and safe evaporating processes.

KT-AH Hydrogen atmosphere furnace - induction gas furnace for sintering/annealing with built-in safety features, dual housing design, and energy-saving efficiency. Ideal for lab and industrial use.

Efficiently separate "low boiling" solvents with the 20L Rotary Evaporator, ideal for chemical labs in pharmaceutical and other industries. Guarantees working performance with selected materials and advanced safety features.

Efficiently separate low boiling solvents with KT Rotary Evaporator. Guaranteed performance with high-grade materials and flexible modular design.

Related Articles

Electric Rotary Kiln Pyrolysis Furnace: A Comprehensive Guide to Pyrolysis Technology

Discover the principles, applications, and advantages of electric rotary kiln pyrolysis furnaces. Explore various heating methods, factors affecting efficiency, and the environmental benefits of this technology.

Biomass Pyrolysis Equipment A Sustainable Solution for Waste Management

Biomass pyrolysis has gained increased attention as a sustainable solution for waste management and renewable energy generation.

Biomass Pyrolysis An Effective Means of Producing Biofuels

Biomass pyrolysis is a process that involves heating organic matter in the absence of oxygen to break it down into smaller molecules. This technology has gained popularity due to its potential to produce biofuels.

How Biomass Pyrolysis Machines Work A Comprehensive Overview

Biomass pyrolysis machines are designed to convert biomass materials into useful products such as biochar, bio-oil, and syngas.

The Advantages and Disadvantages of Different Biomass Feedstocks for Pyrolysis

Different feedstocks have their own unique advantages and disadvantages for pyrolysis, which must be carefully considered when selecting the most suitable feedstock for a particular application.

markdown to html 用

How Biomass Pyrolysis Can Help Meet Growing Energy Demands

Biomass pyrolysis is a process that converts organic material into energy-rich biofuels through heating in the absence of oxygen. This renewable energy source is becoming increasingly popular due to its environmental and economic benefits.

6 Ways To activated carbon regeneration

Activated Carbon Regeneration: Thermal Regeneration Method, Biological Regeneration Method, Wet Oxidation Regeneration Method, Solvent Regeneration Method, Electrochemical Regeneration Method, Catalytic Wet Oxidation Method

Comprehensive Guide to Hydraulic Hot Press: Function, Features and Applications

Hydraulic hot press is equipped with advanced electronic controls that allow for precise temperature selection and technical control. This enables the machine to automatically carry out processes such as stage temperature adjustment and film pressure control.