In essence, a CVD diamond is a lab-grown diamond created through a process called Chemical Vapor Deposition. This technique doesn't imitate a diamond; it grows a real one, atom by atom, by exposing a diamond "seed" to a carbon-rich gas in a high-temperature vacuum chamber. The resulting material is chemically, physically, and optically identical to a mined diamond, possessing the same exceptional hardness and thermal conductivity.

The core concept behind the CVD process is control. By growing a diamond layer by layer in a highly controlled environment, we can produce a material with exceptional purity and specific properties tailored for advanced applications where natural diamonds are either too expensive or inconsistent.

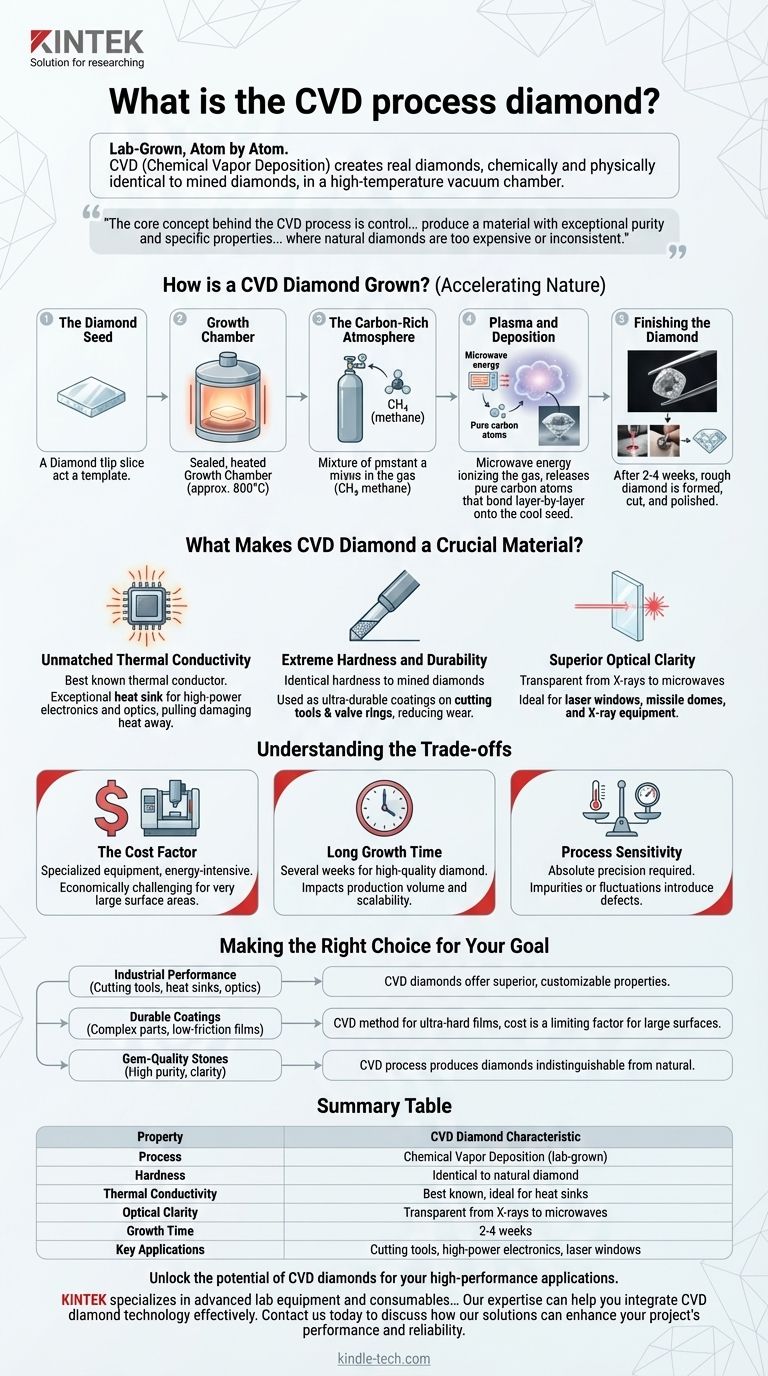

How is a CVD Diamond Grown?

The CVD process mimics natural diamond formation, but accelerates it from millions of years to a matter of weeks. The entire operation hinges on creating the perfect conditions for carbon atoms to crystallize.

The Diamond Seed

The process begins with a thin, flat slice of a previously grown diamond, known as a seed. This seed acts as the template or foundation upon which the new diamond crystal will form.

The Growth Chamber

This diamond seed is placed inside a sealed vacuum chamber. The chamber is heated to an extreme temperature, typically around 800°C, to prepare the environment for crystal growth.

The Carbon-Rich Atmosphere

The chamber is then flooded with a precise mixture of carbon-containing gases, such as methane. This gas serves as the source for the carbon atoms that will build the new diamond.

Plasma and Deposition

Next, energy (often from microwaves) is introduced into the chamber, ionizing the gas and turning it into a plasma. This breaks the gas molecules apart, freeing the carbon atoms. These pure carbon atoms are then drawn down to the cooler diamond seed, bonding to its surface and replicating its crystal structure, layer by layer.

Finishing the Diamond

After two to four weeks, a rough diamond has formed. This rough stone is then removed from the chamber and can be cut with high-precision lasers and polished using traditional techniques to create the final product, whether for industrial use or as a gemstone.

What Makes CVD Diamond a Crucial Material?

The value of CVD diamonds lies in their ability to harness the superlative properties of natural diamond in a repeatable and often more practical way. This opens the door to applications that would otherwise be impossible.

Unmatched Thermal Conductivity

Diamond is the best known thermal conductor. This property makes CVD diamond an exceptional heat sink for high-power electronics, transistors, and optical devices, efficiently pulling damaging heat away from sensitive components.

Extreme Hardness and Durability

With a hardness identical to mined diamonds, CVD films are used as ultra-durable coatings on cutting tools, valve rings, and other mechanical parts. This significantly reduces wear and tear, extending the life and performance of machinery.

Superior Optical Clarity

CVD diamond is transparent across an incredibly broad spectrum of light, from X-rays to microwaves. This makes it the ideal material for creating high-performance windows for lasers, missile domes, and X-ray equipment, where it can withstand extreme conditions without degrading.

Understanding the Trade-offs

While the CVD process is revolutionary, it's essential to recognize its practical limitations. These factors often determine its suitability for a given application.

The Cost Factor

The equipment required for CVD is highly specialized, and the process is energy-intensive. While ideal for high-value components, coating very large surface areas—such as for consumer non-stick cookware—can still be economically challenging.

Long Growth Time

Growing a high-quality diamond takes several weeks. This long cycle time is a fundamental constraint on production volume and can impact the scalability of certain applications.

Process Sensitivity

The quality of the final diamond is entirely dependent on maintaining absolute precision within the growth chamber. Any impurities in the gas or fluctuations in temperature and pressure can introduce defects into the crystal structure.

Making the Right Choice for Your Goal

Deciding between natural, CVD, or another type of diamond depends entirely on the specific demands of your application.

- If your primary focus is industrial performance: CVD diamonds offer superior and customizable properties like thermal conductivity and hardness for cutting tools, heat sinks, and high-end optics.

- If your primary focus is creating durable coatings: The CVD method allows for the application of ultra-hard, low-friction films on complex parts, though cost can be a limiting factor for large surfaces.

- If your primary focus is gem-quality stones: The CVD process produces diamonds with high purity and clarity that are physically and chemically indistinguishable from their natural counterparts.

Ultimately, the CVD process unlocks the remarkable properties of diamond for a new generation of technological and industrial applications.

Summary Table:

| Property | CVD Diamond Characteristic |

|---|---|

| Process | Chemical Vapor Deposition (lab-grown) |

| Hardness | Identical to natural diamond |

| Thermal Conductivity | Best known, ideal for heat sinks |

| Optical Clarity | Transparent from X-rays to microwaves |

| Growth Time | 2-4 weeks |

| Key Applications | Cutting tools, high-power electronics, laser windows |

Unlock the potential of CVD diamonds for your high-performance applications.

KINTEK specializes in advanced lab equipment and consumables, serving the precise needs of laboratories and industrial R&D. Whether you're developing next-generation electronics, durable coatings, or precision optics, our expertise can help you integrate CVD diamond technology effectively.

Contact us today to discuss how our solutions can enhance your project's performance and reliability.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- Can I buy lab diamonds? Your Guide to Modern, Ethical, and Affordable Diamonds

- How plasma is used in diamond coating films? Unlock the Power of MPCVD for Superior Coatings

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What are the cons of lab diamonds? Understanding the Financial and Perceptual Drawbacks

- What is microwave plasma chemical vapor deposition? A Guide to High-Purity Diamond Film Growth

- What factors determine the price of a diamond? A Guide to the 4Cs and Smart Buying

- What is the difference between CVD diamond and natural diamond? A Guide to Making an Informed Choice

- What are the raw materials for CVD diamonds? A seed, a gas, and the science of crystal growth.