In the world of metallurgy, annealing and quenching are two fundamental heat treatment processes that produce nearly opposite results. While both begin by heating a metal to a specific temperature, the crucial difference lies in the cooling method. Annealing involves slow, controlled cooling to make a metal softer, more ductile, and to relieve internal stress. Quenching, by contrast, uses rapid, drastic cooling to make certain steels exceptionally hard and brittle.

The core difference is not the heating, but the cooling. Your choice between annealing and quenching is a choice between two distinct goals: making a metal easy to work with (annealing) or making it extremely hard and wear-resistant (quenching).

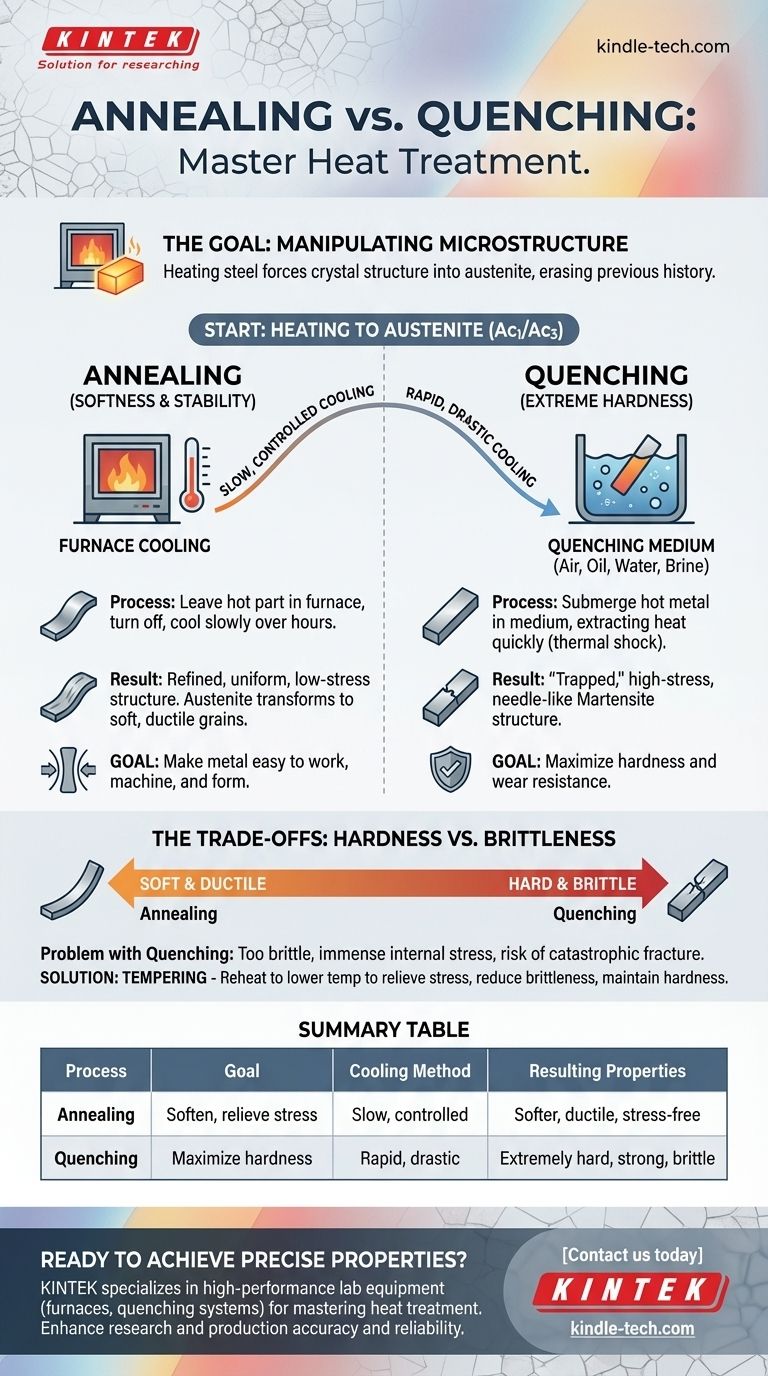

The Goal of Heat Treatment: Manipulating Microstructure

To understand these processes, you must first understand why metal is heated at all. The goal is to deliberately change its internal crystal structure, or microstructure, to achieve a desired set of physical properties.

Why Heat Metal in the First Place?

Heating steel above a critical temperature (often referred to as Ac1 or Ac3) forces its crystal structure into a state called austenite. This austenitic state is the necessary starting point for both annealing and quenching. It is a uniform structure that effectively erases the metal's previous microstructural history.

The Critical Role of the Cooling Rate

Once the metal is in its austenitic state, the speed at which it is cooled dictates the final microstructure and, therefore, its hardness, ductility, and strength. This cooling rate is the single most important variable separating annealing from quenching.

Annealing: The Path to Softness and Stability

Annealing is a process designed to put a metal into its softest, most stable, and lowest-stress state. It is often used to make a material easier to machine or to undo the effects of work-hardening.

The Process: Slow and Controlled Cooling

As noted in various annealing methods, the defining step is always slow cooling. This is often achieved by leaving the hot part inside the furnace and turning the furnace off, allowing both to cool down together over many hours. In other cases, the part may be buried in an insulating material like sand or ash.

The Result: A Refined, Stress-Free Structure

This slow cooling allows the austenite crystals to transform into a soft and ductile microstructure. The process relieves internal stresses that may have been introduced during previous manufacturing steps like forging, casting, or heavy machining. The final product is uniform, soft, and easy to form.

Quenching: The Path to Extreme Hardness

Quenching is the exact opposite of annealing. Its purpose is to create the hardest possible structure that a steel can achieve, prioritizing hardness and wear resistance above all else.

The Process: Rapid and Drastic Cooling

Instead of slow cooling, quenching involves submerging the hot metal in a medium that extracts heat as quickly as possible. Common quenching mediums, in order of increasing severity, include air, oil, water, and brine (salt water). This sudden temperature drop is a thermal shock.

The Result: A "Trapped," High-Stress Structure

The rapid cooling does not give the austenite time to transform into the soft structures of an annealed part. Instead, it "traps" the carbon atoms in a highly strained, needle-like crystal structure called martensite. Martensite is extremely hard, very strong, and exceptionally brittle.

Understanding the Trade-offs: Hardness vs. Brittleness

Neither process is inherently "better"; they are tools used to achieve specific, often opposing, engineering goals. Understanding their trade-offs is key to using them correctly.

The Hardness-Ductility Spectrum

You cannot have maximum hardness and maximum ductility at the same time. Annealing moves a metal toward the soft and ductile end of the spectrum. Quenching moves it to the hard and brittle end.

The Problem with Quenching: Brittleness and Stress

While a quenched part is extremely hard, it is often too brittle for practical use. The martensitic structure is under immense internal stress, and a sharp impact could cause it to shatter like glass. No engineer wants a gear tooth or a bearing to fracture catastrophically.

The Solution: Tempering

Because of this brittleness, a quenched part is almost always tempered. Tempering is a secondary heat treatment where the part is reheated to a much lower temperature (below the critical Ac1 point) and held for a time. This process relieves the internal stresses and reduces brittleness, albeit with a slight reduction in peak hardness. The final result is a part that is both very hard and tough enough for its intended service.

Making the Right Choice for Your Application

Your choice of heat treatment must be directly aligned with the final performance requirements of the component.

- If your primary focus is workability and stress relief: Annealing is the correct process to soften the material for machining, forming, or to reset its properties before another treatment.

- If your primary focus is maximum hardness and wear resistance: Quenching (followed by tempering) is the necessary path to create a durable component like a knife edge, gear, or cutting tool.

- If your primary focus is improving strength without extreme brittleness: Other related processes like normalizing or different tempering cycles exist to produce results that fall between the extremes of annealing and quenching.

Ultimately, mastering heat treatment means selecting the precise cooling rate that engineers the exact material properties your project demands.

Summary Table:

| Process | Goal | Cooling Method | Resulting Properties |

|---|---|---|---|

| Annealing | Soften metal, relieve stress | Slow, controlled (e.g., furnace cooling) | Softer, more ductile, stress-free |

| Quenching | Maximize hardness | Rapid, drastic (e.g., oil or water) | Extremely hard, strong, but brittle |

Ready to achieve precise material properties in your lab? KINTEK specializes in high-performance lab equipment, including furnaces and quenching systems, to help you master heat treatment processes like annealing and quenching. Whether you're developing durable components or refining material workability, our solutions ensure accuracy and reliability. Contact us today to discuss your laboratory needs and discover how KINTEK can enhance your research and production outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What are the four types of heat treating processes? Master Annealing, Normalizing, Hardening, and Tempering

- How does heat treatment process work? Tailor Material Properties for Your Application