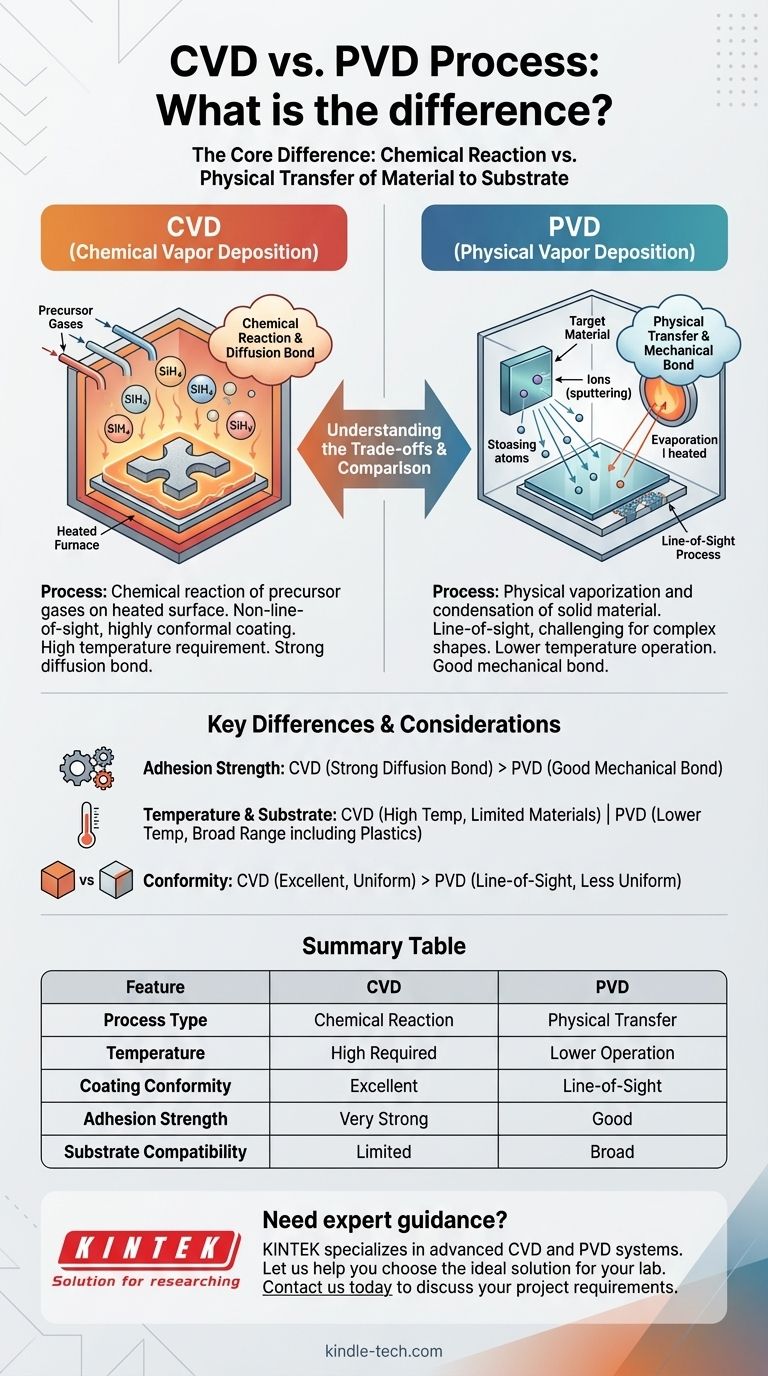

At their core, the difference between Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) lies in how the coating material reaches the substrate. CVD uses a chemical reaction between precursor gases on the substrate's surface to grow a film, while PVD physically transfers material from a solid source to the substrate through a vacuum.

The central decision between CVD and PVD hinges on a fundamental trade-off: CVD provides a highly conformal and strongly bonded coating but requires high temperatures, while PVD operates at lower temperatures suitable for more materials but is a line-of-sight process.

The Fundamental Process: Chemical vs. Physical

Understanding how each method deposits a thin film is the first step in selecting the right process for your application. The names themselves reveal the core distinction.

How CVD Works: A Chemical Reaction

In Chemical Vapor Deposition, volatile precursor gases are introduced into a reaction chamber. These gases decompose and react on the surface of the heated substrate, forming a solid, thin film.

The key is the chemical reaction itself. This process creates a diffusion-type bond between the coating and the substrate, resulting in exceptionally strong adhesion.

How PVD Works: A Physical Transfer

Physical Vapor Deposition is a mechanical process. A solid source material (the "target") is vaporized inside a vacuum chamber, typically through methods like sputtering or evaporation.

These vaporized atoms then travel in a straight line through the vacuum and condense onto the substrate, forming the coating. It is a physical transfer, not a chemical one.

Key Differences in Application and Outcome

The differences in the underlying processes lead to significant variations in performance, application, and material compatibility.

Coating Conformity

CVD is not a line-of-sight process. The precursor gases can flow around and into complex geometries, resulting in a highly uniform and consistent coating thickness, even on intricate shapes.

PVD is a line-of-sight process. The vaporized material travels in a straight path, which can make it challenging to evenly coat complex surfaces with undercuts or hidden areas.

Temperature Requirements

CVD generally requires very high processing temperatures to drive the necessary chemical reactions. This can limit its use to substrates that can withstand significant heat without deforming or degrading.

PVD operates at much lower temperatures under a vacuum. This makes it a far more versatile option for temperature-sensitive materials like plastics, certain alloys, and other advanced substrates.

Adhesion and Bond Strength

The chemical bonding inherent in the CVD process typically creates a stronger, more durable bond with the substrate compared to PVD.

While PVD provides excellent adhesion, the bond is primarily mechanical and can be less robust than the diffusion bond formed by CVD.

Understanding the Trade-offs

Neither process is universally superior. The optimal choice depends entirely on the priorities of your specific project.

Substrate Compatibility

The most significant limitation of CVD is its high heat requirement, which immediately disqualifies many temperature-sensitive materials.

PVD's lower temperature operation gives it a much broader range of compatible substrates, making it the default choice for many modern applications.

Process Complexity and Safety

CVD can be a complex process involving toxic, corrosive, or flammable chemicals. This requires significant safety protocols and specialized handling.

PVD is generally considered a safer process as it doesn't typically involve harmful precursor gases, though proper handling of the vacuum chamber is still critical.

Cost and Automation

PVD systems often require more specialized and expensive equipment, which can lead to higher initial costs than some CVD setups.

However, the PVD process can often be more easily automated, which can be an advantage for high-volume production environments.

Making the Right Choice for Your Goal

To select the correct method, you must align the process characteristics with your operational needs and desired coating properties.

- If your primary focus is maximum adhesion and uniform coating on complex shapes: CVD is the superior choice, but only if your substrate can tolerate the high processing temperatures.

- If your primary focus is coating a temperature-sensitive material: PVD is the necessary and more versatile option due to its significantly lower temperature requirements.

- If your primary focus is process safety and simpler workflow: PVD generally offers a safer and more straightforward process by avoiding hazardous chemical precursors.

Ultimately, choosing the right deposition method requires a clear understanding of both your material's limitations and your performance goals.

Summary Table:

| Feature | CVD (Chemical Vapor Deposition) | PVD (Physical Vapor Deposition) |

|---|---|---|

| Process Type | Chemical reaction of gases | Physical transfer of material |

| Temperature | High temperature required | Lower temperature operation |

| Coating Conformity | Excellent, non-line-of-sight | Line-of-sight, less uniform on complex shapes |

| Adhesion Strength | Very strong (diffusion bond) | Good (mechanical bond) |

| Substrate Compatibility | Limited to high-temperature materials | Broad, including temperature-sensitive materials |

Need expert guidance on selecting the right deposition process for your laboratory's specific application? KINTEK specializes in providing high-quality lab equipment and consumables, including advanced CVD and PVD systems. Our team can help you choose the ideal solution to enhance coating performance, improve efficiency, and ensure compatibility with your materials. Contact us today to discuss your project requirements and discover how our expertise can benefit your research or production workflow!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method