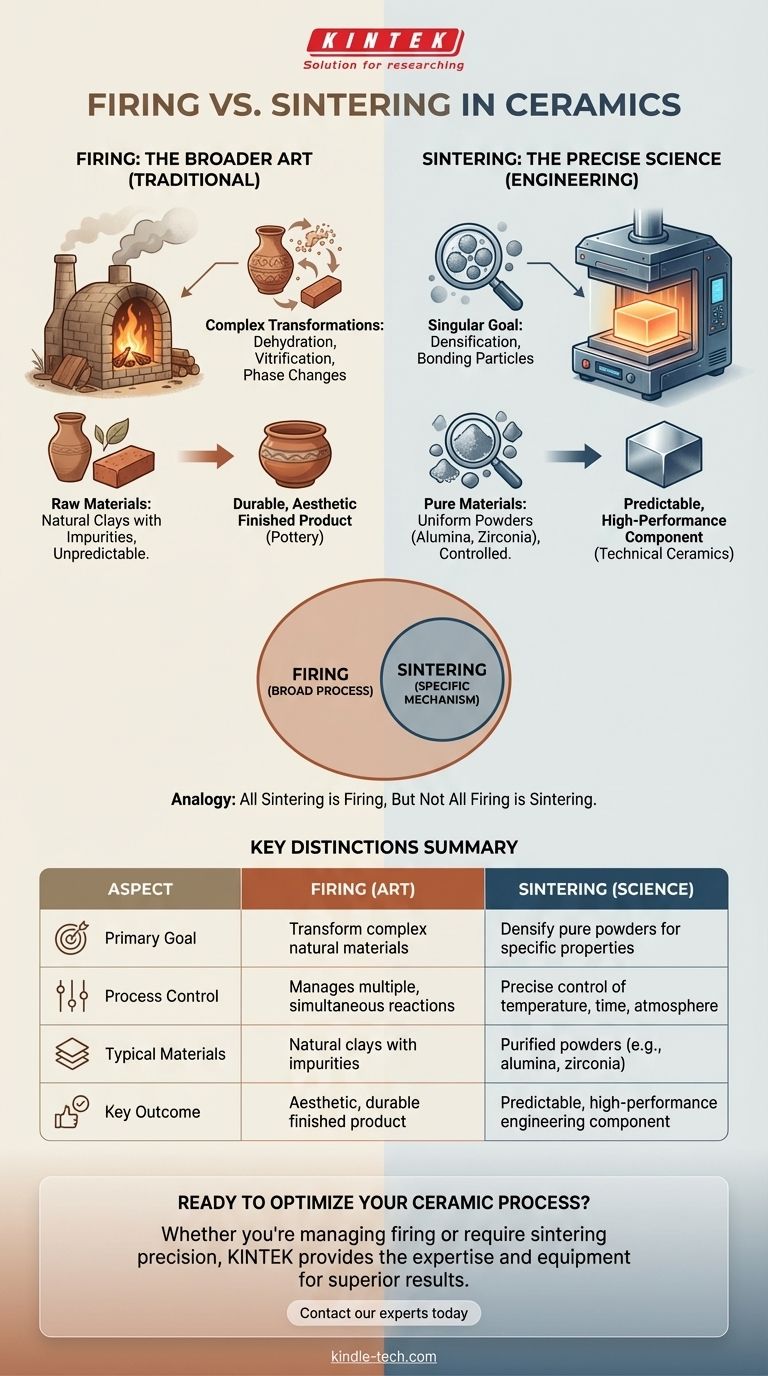

In the world of ceramics, the terms firing and sintering are often used interchangeably, but they represent a critical distinction in process control and intent. Firing is a broad, traditional term for heating ceramic materials, especially complex natural clays. Sintering, in contrast, is a specific, scientifically-defined process of densifying a powder compact under tightly controlled conditions, and is technically a type of firing.

The core difference lies in complexity and control. Think of firing as the broad art of heating a complex material like natural clay, where many chemical and physical changes happen at once. Sintering is the precise science of engineering a pure material by fusing particles together to achieve specific, repeatable properties.

What is Firing? The Broader Art

Firing is best understood as a general term for the heat treatment that transforms a raw ceramic body into a durable, finished product. It encompasses a whole series of changes, not just a single mechanism.

A Process of Transformation

When a traditional ceramic piece is fired, it undergoes multiple simultaneous reactions. These can include water removal (dehydration), the burning off of organic matter, phase transformations of minerals, and the formation of glass (vitrification).

The Complexity of Natural Materials

The term "firing" is most common in pottery and traditional ceramics precisely because the raw materials, like natural clays, are chemically complex. They contain a mix of different minerals and impurities that react unpredictably. Firing is the process of managing this entire complex transformation.

What is Sintering? The Precise Science

Sintering is the specific mechanism of using thermal energy to bond particles together, reducing the empty space (porosity) between them and increasing the material's density. This is the dominant process in manufacturing advanced and technical ceramics.

The Goal is Pure Densification

Unlike the multifaceted process of firing clay, the primary goal of sintering is singular: densification. The process involves atoms moving across the boundaries of adjacent particles, forming "necks" that grow until the individual particles fuse into a solid, coherent mass.

Control is Paramount

Sintering is associated with materials science and engineering. It starts with highly purified, uniform powders (like alumina or zirconia) and uses precisely controlled parameters—temperature, time, and atmosphere—to achieve a predictable outcome and specific engineering properties like exceptional hardness or electrical resistance.

Understanding the Key Distinction

While related, the two terms describe different levels of scientific understanding and control over the process. A simple analogy helps clarify the relationship.

All Sintering is Firing, But Not All Firing is Sintering

Sintering is a specific, definable mechanism that occurs during a firing process. However, a firing process can involve many other mechanisms besides sintering. It's like how a square is a type of rectangle, but not all rectangles are squares.

Traditional vs. Technical Ceramics

This distinction often follows the type of ceramic being made. Potters fire their clay to create art. Materials engineers sinter zirconium oxide powder to create a high-performance blade. The language reflects the difference between managing a complex natural system and engineering a purified one.

Common Pitfalls to Avoid

Confusing these terms can lead to a misunderstanding of your material and process, resulting in failed outcomes.

Applying Sintering Principles to Clay

One cannot simply take a sintering temperature profile for pure alumina and apply it to a natural earthenware clay. The clay's complex composition, including fluxes and impurities, means it will melt or deform at temperatures where a technical ceramic is just beginning to densify.

Ignoring the "Firing" Aspects of Sintering

Even in a highly controlled sintering process, other firing-related phenomena can occur. Unwanted chemical reactions with the furnace atmosphere or the burn-off of binder agents are part of the overall thermal process that must be managed for success.

How to Apply This to Your Process

Choosing the right mental model—firing or sintering—depends entirely on your material and your final goal.

- If your primary focus is artistic pottery or traditional ceramics: Think in terms of firing. Your goal is to skillfully manage a complex series of reactions in a natural material to achieve a desired aesthetic.

- If your primary focus is creating a high-performance engineering component: Think in terms of sintering. Your goal is to use precise control over pure materials to achieve specific, repeatable, and measurable physical properties.

Ultimately, understanding whether you are practicing the broad art of firing or the precise science of sintering is the first step toward mastering your ceramic material.

Summary Table:

| Aspect | Firing (Art) | Sintering (Science) |

|---|---|---|

| Primary Goal | Transform complex natural materials (e.g., clay) | Densify pure powders for specific properties |

| Process Control | Manages multiple, simultaneous reactions | Precise control of temperature, time, atmosphere |

| Typical Materials | Natural clays with impurities | Purified powders (e.g., alumina, zirconia) |

| Key Outcome | Aesthetic, durable finished product | Predictable, high-performance engineering component |

Ready to optimize your ceramic process? Whether you're managing the complex reactions of firing natural clays or require the precision of sintering for advanced materials, KINTEK has the expertise and equipment to ensure your success. As your specialized partner in lab equipment and consumables, we provide the precise thermal solutions and expert support your laboratory needs. Contact our experts today to discuss how we can help you achieve superior results!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the effects of sintering on the powder compact produced by pressing? Achieve Strong, Dense Parts

- What is regeneration gas? A Key to Efficient and Continuous Industrial Purification

- What is the requirement of heat treatment? Unlock Your Material's Full Potential

- What is the temperature of the arc melting furnace? Achieve 3000°C for Refractory Metals

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What materials are used in high temperature furnace? Uncover the Key Components for Extreme Heat

- What is sintered metal? A Complete Guide to Its Process and Benefits

- What is the pressure on a vacuum furnace? Mastering the Key to Process Purity and Quality