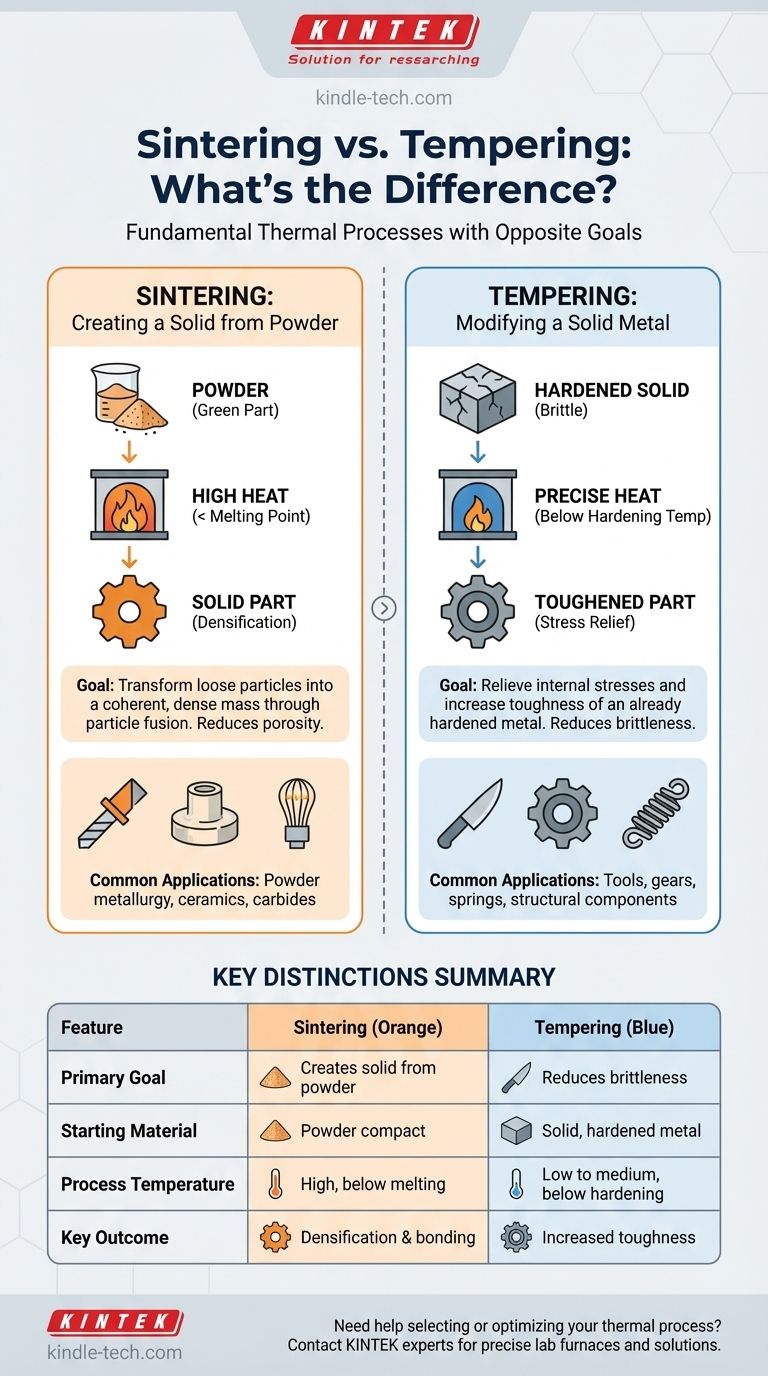

At their core, tempering and sintering are fundamentally different thermal processes with opposite goals. Sintering is a manufacturing method that uses heat to fuse powders into a solid object, while tempering is a finishing step that uses heat to reduce the brittleness of an already solid, hardened metal part. They are not interchangeable and apply to entirely different stages of a material's life cycle.

The critical distinction is the starting material and the final objective. Sintering creates a solid, dense part from a powder. Tempering modifies an existing solid part to make it less brittle and more durable.

The Goal of Sintering: Creating a Solid from Powder

Sintering is a primary manufacturing process, particularly in the fields of powder metallurgy and ceramics. Its entire purpose is to transform a collection of loose particles into a coherent, solid mass.

What is Sintering?

Sintering involves taking a compacted powder, often called a "green part," and heating it to a high temperature that is below the material's melting point.

This process reduces the porosity between the starting particles, causing the object to shrink and increase in density. As noted in hot pressing, a form of sintering, this can be an "activated" process where pressure is also applied to accelerate densification.

The Mechanism: Fusing Particles

Instead of melting the material, sintering encourages atoms to diffuse across the boundaries of the particles, creating strong bonds between them.

The goal is to eliminate the empty spaces (pores) and fuse the powder into a single, dense piece. The environment, such as the presence of gases like hydrogen or nitrogen, can be critical for achieving full density in specific materials like nitrides or metals.

Common Applications

Sintering is essential for creating parts from materials with extremely high melting points that are difficult or impossible to cast, such as tungsten filaments, carbide cutting tools, and advanced ceramics.

The Goal of Tempering: Modifying a Solid Metal

Tempering is a secondary heat treatment process. It is never used to create an object but rather to refine the properties of one that has already been formed and hardened.

What is Tempering?

Tempering is almost always performed on ferrous metals like steel after they have been subjected to a hardening process (quenching). Hardening makes steel very hard but also extremely brittle and internally stressed.

The process involves reheating the hardened part to a precise temperature well below its hardening temperature, holding it for a specific time, and then cooling it.

The Mechanism: Relieving Internal Stress

The heat from tempering allows the carbon atoms within the steel's crystal structure (microstructure) to rearrange slightly. This relieves the immense internal stresses created during quenching.

This microstructural change decreases hardness and brittleness while significantly increasing the material's toughness—its ability to deform and absorb energy without fracturing.

Common Applications

Tempering is critical for creating tools and machine parts that need to be both hard enough to hold an edge or resist wear, but also tough enough to withstand impact and shock. Examples include knife blades, axes, gears, and structural steel components.

Understanding the Key Distinctions

The confusion between these two processes stems from their shared use of heat. However, a direct comparison reveals their fundamental differences.

Starting Material: Powder vs. Solid

This is the clearest distinction. Sintering begins with a powder. Tempering begins with a fully formed, solid metal part that has already been hardened.

Process Temperature: Below Melting vs. Below Critical Point

Sintering heats a material to just under its melting point to encourage particle diffusion. Tempering heats a hardened metal to a much lower temperature, specifically below its lower critical temperature, to avoid undoing the previous hardening treatment.

Primary Outcome: Densification vs. Toughness

The end goal of sintering is densification—turning a porous powder compact into a solid object. The end goal of tempering is to improve toughness by reducing the brittleness of an already hard material.

Making the Right Choice for Your Goal

The correct process depends entirely on what you are starting with and what you need to achieve.

- If your primary focus is creating a solid part from metal or ceramic powder: You need sintering to fuse the particles and achieve the desired density and shape.

- If your primary focus is making a hardened steel part less brittle: You need tempering to relieve internal stresses and increase its toughness and durability.

- If your primary focus is joining two separate components: Neither process is correct; you should consider welding, brazing, or soldering, which use a molten filler material to create a bond.

Understanding the fundamental purpose of each process—creating a part versus modifying a property—is the key to mastering these material treatments.

Summary Table:

| Feature | Sintering | Tempering |

|---|---|---|

| Primary Goal | Creates a solid part from powder | Reduces brittleness in a hardened solid part |

| Starting Material | Powder compact ("green part") | Solid, hardened metal (e.g., quenched steel) |

| Process Temperature | High, but below the material's melting point | Low to medium, well below the hardening temperature |

| Key Outcome | Densification and particle bonding | Increased toughness and stress relief |

| Common Applications | Powder metallurgy parts, ceramics, carbide tools | Knife blades, gears, springs, structural components |

Need help selecting or optimizing your thermal process?

Whether you are developing new materials via sintering or improving the durability of metal components with tempering, KINTEK's expertise in lab furnaces and thermal processing equipment is here to support you. We provide the precise, reliable tools you need to achieve perfect results.

Contact our experts today to discuss how KINTEK's solutions can enhance your laboratory's capabilities in material science and heat treatment.

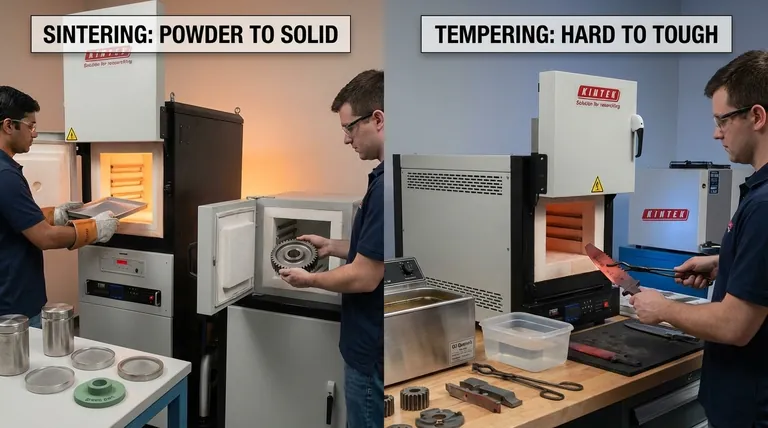

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- What is sintering reaction? Transform Powders into Dense Solids Without Melting

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- Why is a high vacuum environment necessary in sintering equipment for TiAl alloys? Ensure High-Purity Metal Bonding