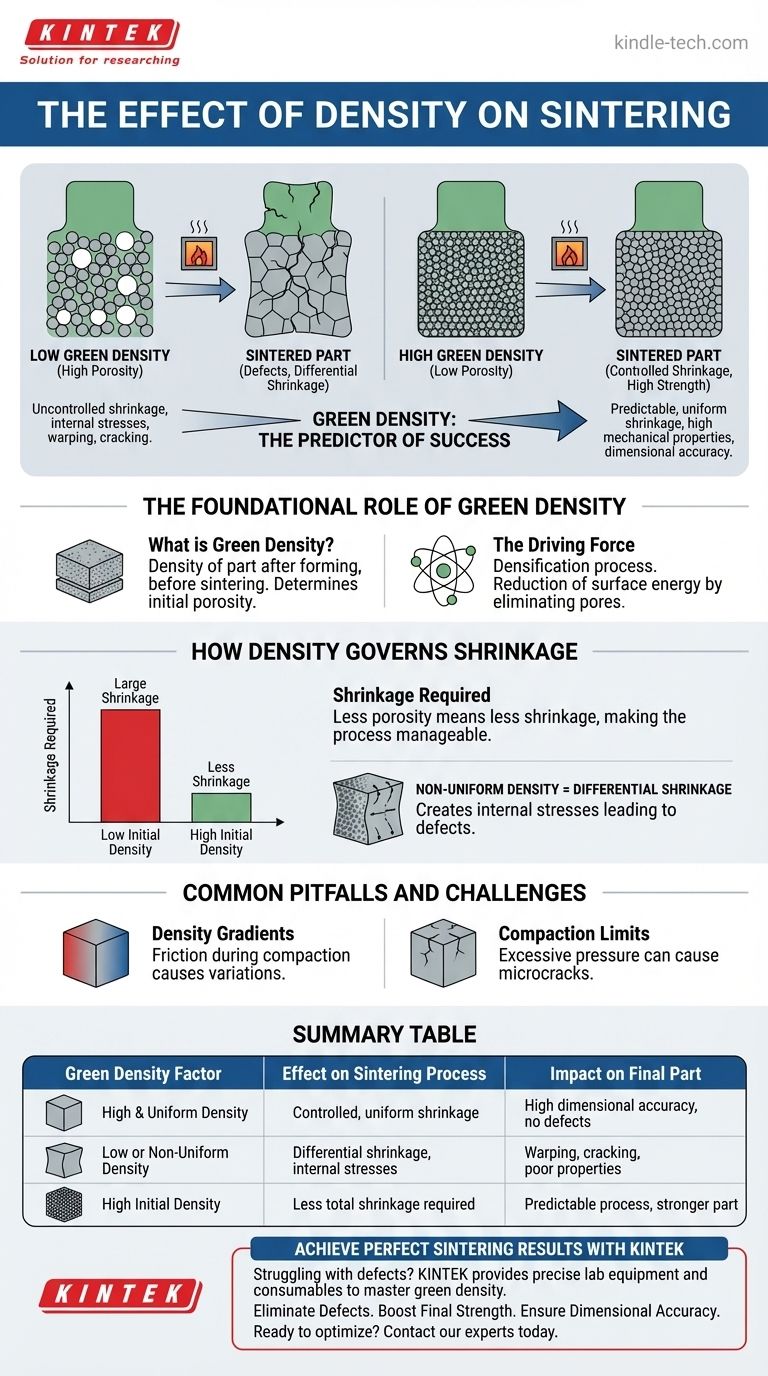

In short, green density is the single most critical predictor of sintering success. A higher and more uniform initial density of the compacted powder (the "green" part) directly leads to more controlled, uniform shrinkage during heating. This minimizes the risk of defects like warping and cracking, resulting in a stronger, more dimensionally accurate final component.

The core principle is straightforward: sintering works by eliminating the empty space (porosity) between powder particles. The initial density of your part simply defines the starting amount of that empty space, which in turn dictates how much the part must shrink to become solid.

The Foundational Role of Green Density

To understand the effect of density on sintering, we must first distinguish between the state of the material before and after heating. The initial density is the key variable you can control.

What is Green Density?

Green density is the density of a part after it has been formed or pressed from a powder, but before it undergoes the high-temperature sintering process. It represents how tightly the individual powder particles are packed together.

A part with low green density has a large amount of void space, or porosity, between its particles. A part with high green density has much less porosity and more particle-to-particle contact.

The Driving Force of Sintering

Sintering is fundamentally a process of densification. At high temperatures, atoms diffuse across the boundaries of particles, effectively fusing them together and closing the pores between them.

This process is driven by the reduction of surface energy. A porous powder compact has a massive amount of surface area, which is energetically unfavorable. Sintering reduces this energy by transforming those surfaces into solid grain boundaries, causing the entire part to shrink and densify.

How Density Directly Governs Shrinkage

The connection between initial density and final outcome is a direct consequence of this densification process. Advanced ceramics, for example, often shrink by as much as 20-25% to reach their final density.

Less Porosity Means Less Shrinkage

The most direct effect is on the total amount of shrinkage required. A part that starts at 50% of its theoretical maximum density must shrink significantly more to reach a final density of 99% than a part that starts at 65% green density.

By starting with a higher green density, you reduce the total volumetric change the part must undergo, making the entire process more predictable and manageable.

Uniform Density Prevents Warping and Cracking

Uniformity of green density is even more critical than its absolute value. If one section of a part is denser than another, it will shrink at a different rate during sintering.

This differential shrinkage creates immense internal stresses within the component. These stresses are the primary cause of common sintering defects such as warping, distortion, and cracking. A uniform green density ensures the entire part shrinks cohesively.

The Impact on Final Microstructure

A higher and more uniform green density typically leads to a more homogenous final microstructure. This means smaller, more uniform grain sizes and fewer isolated, hard-to-remove pores in the final part, which directly translates to improved mechanical properties like strength and fracture toughness.

Common Pitfalls and Challenges

While aiming for high, uniform density is the goal, achieving it presents its own set of practical challenges.

The Problem of Density Gradients

Achieving perfectly uniform density, especially in complex shapes, is difficult. Friction between the powder and the die walls during compaction can cause some areas (like corners or thin walls) to be less dense than others. These built-in density gradients are a primary source of failure.

The Limits of Compaction

Simply increasing compaction pressure to boost density has its limits. Extremely high pressures can introduce microcracks or laminations in the green part that worsen during sintering. The characteristics of the powder itself, such as particle size distribution and shape, also play a huge role in how well it can be packed.

Making the Right Choice for Your Process

Controlling your green density is not just a preliminary step; it is the foundational action for a successful sintering outcome. Your specific goals will determine where you focus your efforts.

- If your primary focus is dimensional accuracy: Aim for the highest and most uniform green density possible to minimize total shrinkage and make it highly predictable.

- If you are struggling with cracking or warping: Your first step should be to diagnose and eliminate density gradients in your green parts.

- If you need to maximize final part strength: Focus on achieving a high green density to minimize residual porosity, which acts as a stress concentrator in the final ceramic.

Ultimately, mastering your forming process to control green density gives you direct control over the integrity and quality of your final sintered component.

Summary Table:

| Green Density Factor | Effect on Sintering Process | Impact on Final Part |

|---|---|---|

| High & Uniform Density | Controlled, uniform shrinkage | High dimensional accuracy, no warping/cracking |

| Low or Non-Uniform Density | Differential shrinkage, internal stresses | Warping, cracking, poor mechanical properties |

| High Initial Density | Less total shrinkage required | Predictable process, stronger part |

Achieve Perfect Sintering Results with KINTEK

Struggling with warping, cracking, or inconsistent shrinkage in your sintered components? The root cause often lies in uncontrolled green density. KINTEK specializes in providing the precise lab equipment and consumables you need to master your forming process.

We help you:

- Eliminate Defects: Achieve uniform green density to prevent differential shrinkage and internal stresses.

- Boost Final Strength: Maximize part integrity by minimizing residual porosity.

- Ensure Dimensional Accuracy: Gain predictable, controlled shrinkage for highly accurate components.

Ready to transform your sintering outcomes? Contact our experts today to discuss how KINTEK's solutions can optimize your process and deliver superior quality parts.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics