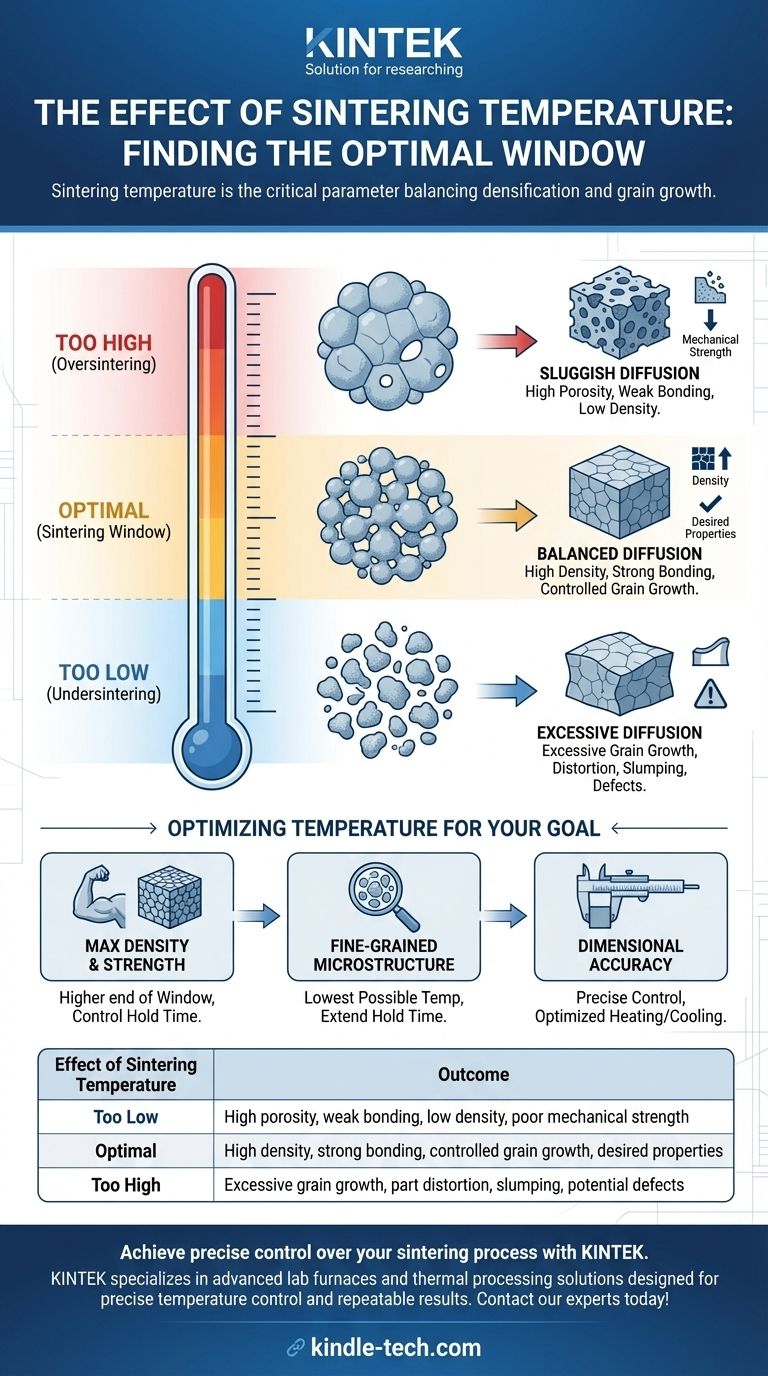

In short, sintering temperature is the single most critical parameter that controls the transformation of a loose powder compact into a dense, solid object. It provides the thermal energy needed for atoms to move and bond between particles, a process known as diffusion. The correct temperature dictates the final density, strength, and microstructure of the component.

The core challenge of sintering is that temperature has competing effects. While higher temperatures increase densification and strength, they also risk excessive grain growth, distortion, and defects. The key is to operate within an optimal "sintering window" that balances these outcomes.

The Fundamental Role of Temperature: Driving Diffusion

Sintering works by heating a material to a temperature below its melting point. This energy input activates atomic movement, causing individual particles to bond and the overall part to densify.

Activating Atomic Movement

At room temperature, atoms in a powder compact are largely static. As temperature increases, it provides the necessary kinetic energy for atoms to migrate from one particle to another. This atomic transport is the fundamental mechanism behind sintering.

The Diffusion Process

This atomic movement, or diffusion, is heavily dependent on temperature. The two primary mechanisms are bulk diffusion (atoms moving through the crystal lattice) and grain boundary diffusion (atoms moving along the boundaries between crystals). Both accelerate exponentially as temperature rises.

The Goal: Neck Growth and Densification

Diffusion causes "necks" to form and grow at the contact points between powder particles. As these necks expand, the pores (empty spaces) between particles shrink and are gradually eliminated. This process, known as densification, increases the part's density and, consequently, its mechanical strength.

How Temperature Shapes the Final Microstructure

The temperature profile—including the peak temperature and how long it is held—directly determines the final characteristics of the sintered part.

Controlling Density and Porosity

Higher sintering temperatures lead to faster diffusion rates. This results in more complete pore removal, yielding a part with higher final density and lower residual porosity. For most structural applications, achieving near-full density is the primary goal.

The Unwanted Effect: Grain Growth

Simultaneously, the thermal energy that drives densification also drives grain growth. As particles fuse, the small crystalline grains tend to coalesce into larger ones. Excessive grain growth can be detrimental, often reducing the material's hardness and toughness.

Understanding the Trade-offs: The Sintering Window

The success of a sintering process hinges on balancing the positive effect of densification against the negative effects of excessive temperature.

The Risk of Undersintering

If the temperature is too low, diffusion is sluggish and insufficient. The result is poor bonding between particles, high porosity, and a mechanically weak component that has not achieved its target density or properties.

The Danger of Oversintering

If the temperature is too high or held for too long, several problems arise.

- Excessive Grain Growth: As noted, this can degrade mechanical properties.

- Distortion and Slumping: As the temperature approaches the material's melting point, the part can lose its structural integrity and begin to sag or warp under its own weight, a major source of defects.

- Friction Effects: High temperatures can also exacerbate friction between the part and its support surface, leading to cracks or distortion upon cooling.

Finding the "Sintering Window"

The sintering window is the ideal temperature range for a specific material. It is high enough to achieve the desired densification in a reasonable time but low enough to prevent excessive grain growth, slumping, and other heat-related defects.

Optimizing Temperature for Your Goal

The ideal sintering temperature is not a single value but is determined by the desired properties of the final component.

- If your primary focus is maximum density and strength: You will likely operate at the higher end of the material's sintering window, carefully controlling the heating rate and hold time to prevent distortion.

- If your primary focus is a fine-grained microstructure: You should aim for the lowest possible temperature that still achieves your target density, often by extending the hold time or using finer starting powders.

- If your primary focus is dimensional accuracy and avoiding defects: You must precisely control the temperature to avoid slumping and use a well-designed heating and cooling cycle to minimize thermal stress.

Mastering temperature control is the essential skill for converting the potential of a powder material into a high-performance, reliable component.

Summary Table:

| Effect of Sintering Temperature | Outcome |

|---|---|

| Too Low (Undersintering) | High porosity, weak bonding, low density, poor mechanical strength |

| Optimal (Sintering Window) | High density, strong bonding, controlled grain growth, desired properties |

| Too High (Oversintering) | Excessive grain growth, part distortion, slumping, potential defects |

Achieve precise control over your sintering process with KINTEK.

Mastering the sintering window is critical for producing high-performance components with the right density, strength, and microstructure. Whether your goal is maximum strength, a fine-grained structure, or perfect dimensional accuracy, the right equipment is essential.

KINTEK specializes in advanced lab furnaces and thermal processing solutions designed for precise temperature control and repeatable results. Our expertise helps you optimize your sintering cycle to avoid defects and achieve your material goals.

Contact our thermal processing experts today to discuss how our solutions can enhance your sintering outcomes. Let us help you find the perfect balance for your materials.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What are laser sintering methods? Unlock Complex 3D Printing with Powder Bed Fusion

- What is the pressureless sintering process? A Guide to Simpler, Cost-Effective Material Consolidation

- What are the technical requirements for vacuum chambers in desalination? Boost Efficiency with Graphene Technology

- Why is a magnetic stirrer considered essential during PdLa/ATO catalyst preparation? Ensure Uniform Particle Dispersion

- What is the temperature dependence of graphite? Balancing Strength and Oxidation for High-Temp Use

- What are the different types of ovens in the lab? A Guide to Choosing the Right Heating Equipment

- How is an electric constant temperature drying oven utilized in the curing process of Pd/G-SS electrodes?

- When using a rotavap Why should you avoid bumping? Prevent Catastrophic Sample Loss and Contamination