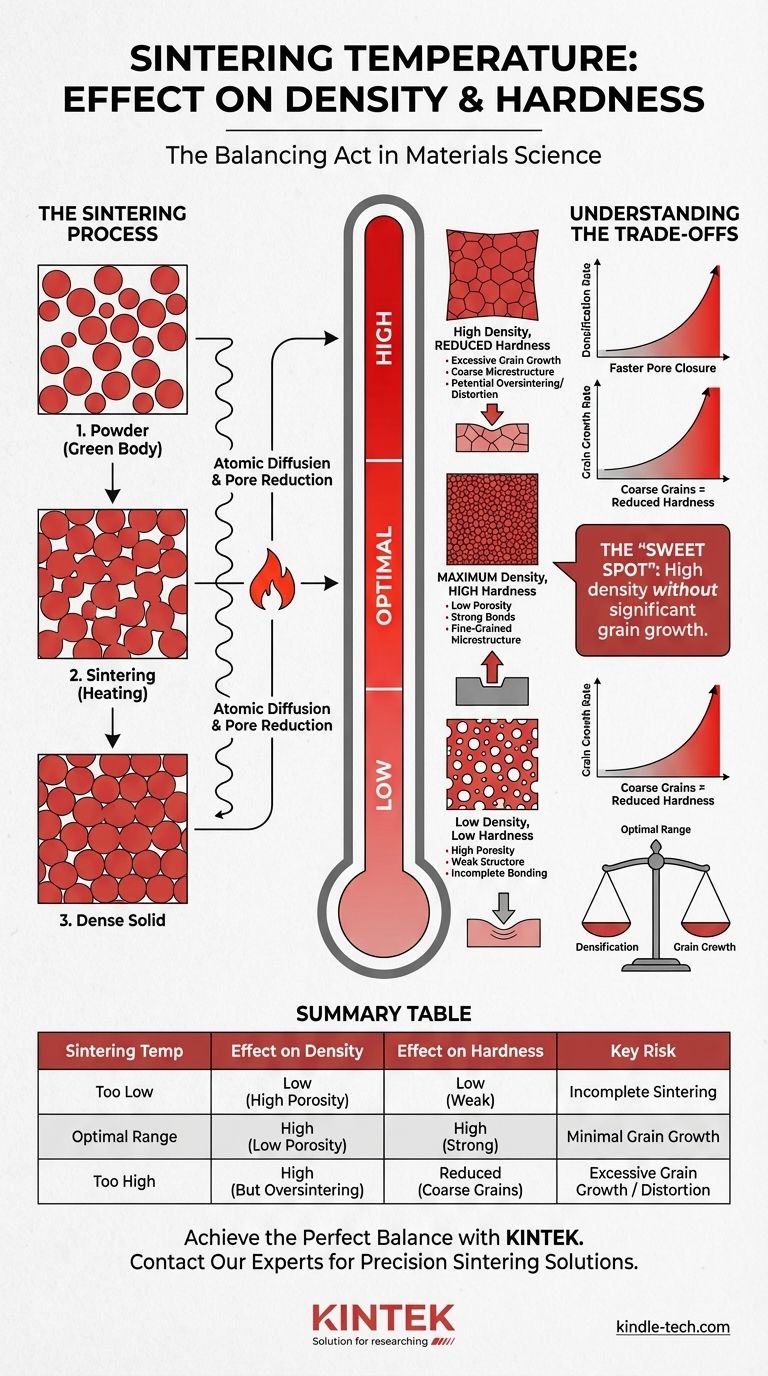

In the field of materials science, increasing the sintering temperature directly and significantly increases both the density and hardness of a material, but only up to an optimal point. This process involves heating a compacted powder (a "green body") to a temperature below its melting point, which allows atoms to diffuse, bond the particles together, and reduce the empty space, or porosity, between them.

Sintering is a balancing act. While higher temperatures are necessary to drive the diffusion that increases density and hardness, excessive heat can trigger undesirable grain growth, which can ultimately compromise the material's mechanical properties.

The Core Mechanism: How Sintering Works

Sintering transforms a loosely packed collection of particles into a dense, solid object. Temperature is the primary lever you control to manage this transformation.

From Powder to Solid

The starting point for sintering is typically a "green body"—a component formed by compressing powder. This body has significant internal porosity, which makes it weak and unsuitable for most engineering applications. The goal of sintering is to eliminate this porosity.

Temperature as the Driving Force

Heat provides the thermal energy necessary for atomic diffusion. Think of it as giving the atoms enough energy to move from the bulk of the particles to the points of contact between them. This movement builds "necks" that grow and eventually close the pores.

The Stages of Densification

This process occurs in stages. First, necks form and grow between adjacent particles. Next, these necks merge, forming a network of interconnected pore channels. In the final stage, these channels break up into isolated, spherical pores, which then slowly shrink and, ideally, disappear entirely, leading to a fully dense material.

The Direct Link: Temperature, Density, and Hardness

The relationship between sintering temperature and final material properties is direct and predictable, governed by the rate of atomic diffusion.

The Impact on Density

As you increase the sintering temperature, the rate of atomic diffusion increases exponentially. This accelerated movement of atoms allows voids to be filled more quickly and completely. The result is a reduction in porosity and a corresponding increase in the overall density of the component. A material sintered at a higher temperature will almost always be denser than one sintered at a lower temperature, assuming all other factors are equal.

The Consequent Effect on Hardness

Hardness is a material's resistance to localized surface indentation or scratching. This property is directly tied to density. Pores are essentially structural defects; they are weak points where cracks can initiate.

By eliminating these pores, sintering creates a more uniform and structurally sound material. The strong, continuous bonds formed between the particles provide a robust structure that effectively resists deformation, thus increasing the material's hardness.

Understanding the Trade-offs: The Dangers of Excessive Temperature

Pushing the temperature too high in search of maximum density can be counterproductive. The key is to find the optimal processing window.

The Onset of Grain Growth

Once the majority of pores have been eliminated and the material is nearing full density, a different phenomenon takes over: grain growth (or coarsening). At elevated temperatures, larger grains begin to consume smaller, neighboring grains. This process reduces the total grain boundary area in the material.

Why Large Grains Can Reduce Hardness

For many crystalline materials, hardness is dictated by the Hall-Petch relationship, which states that hardness increases as grain size decreases. Grain boundaries act as obstacles that impede the movement of dislocations—the primary mechanism of plastic deformation.

More boundaries (smaller grains) mean a harder, stronger material. Uncontrolled grain growth leads to a coarser microstructure with fewer boundaries, which can actually reduce the material's hardness and strength, even if the density is high.

The Risk of Oversintering

Beyond grain growth, excessively high temperatures can lead to oversintering, where localized melting, slumping, or distortion of the component can occur. This ruins the dimensional accuracy and structural integrity of the final part.

Finding the Optimal Sintering Window

Your choice of sintering temperature depends entirely on the specific properties you need to achieve. You must balance the positive effect of densification against the negative effect of grain growth.

- If your primary focus is achieving maximum density: You must increase the temperature to the point where pore closure is maximized, which is often just below the temperature where rapid grain growth begins.

- If your primary focus is maximizing hardness and strength: You need to find the "sweet spot" that yields high density without causing significant grain growth, as a fine-grained microstructure is generally harder.

- If your primary focus is process efficiency and cost: You may opt for the lowest temperature that achieves the minimum acceptable density and hardness for your application, thereby saving energy and time.

Ultimately, controlling sintering temperature is the most powerful tool for engineering the final microstructure and, therefore, the performance of your material.

Summary Table:

| Sintering Temperature | Effect on Density | Effect on Hardness | Key Risk |

|---|---|---|---|

| Too Low | Low (High Porosity) | Low (Weak) | Incomplete Sintering |

| Optimal Range | High (Low Porosity) | High (Strong) | Minimal Grain Growth |

| Too High | High (But Oversintering) | Reduced (Coarse Grains) | Excessive Grain Growth / Distortion |

Achieve the perfect balance of density and hardness in your sintered materials.

At KINTEK, we specialize in providing the advanced lab equipment and expert support you need to precisely control your sintering processes. Our furnaces and consumables are designed to help you find the optimal sintering window for your specific materials, ensuring superior mechanical properties and consistent results.

Don't let improper temperature control compromise your product's performance. Contact our experts today to discuss how KINTEK solutions can enhance your laboratory's capabilities and drive your materials science projects to success.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is environmental control within a vacuum furnace important for diffusion bonding? Master Titanium Alloy Laminates

- What is the sintering time? A Critical Process Variable for Material Density and Strength

- What are the defects in sintered parts? Avoid Warping, Cracking, and Porosity Issues

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- What is sintering reaction? Transform Powders into Dense Solids Without Melting