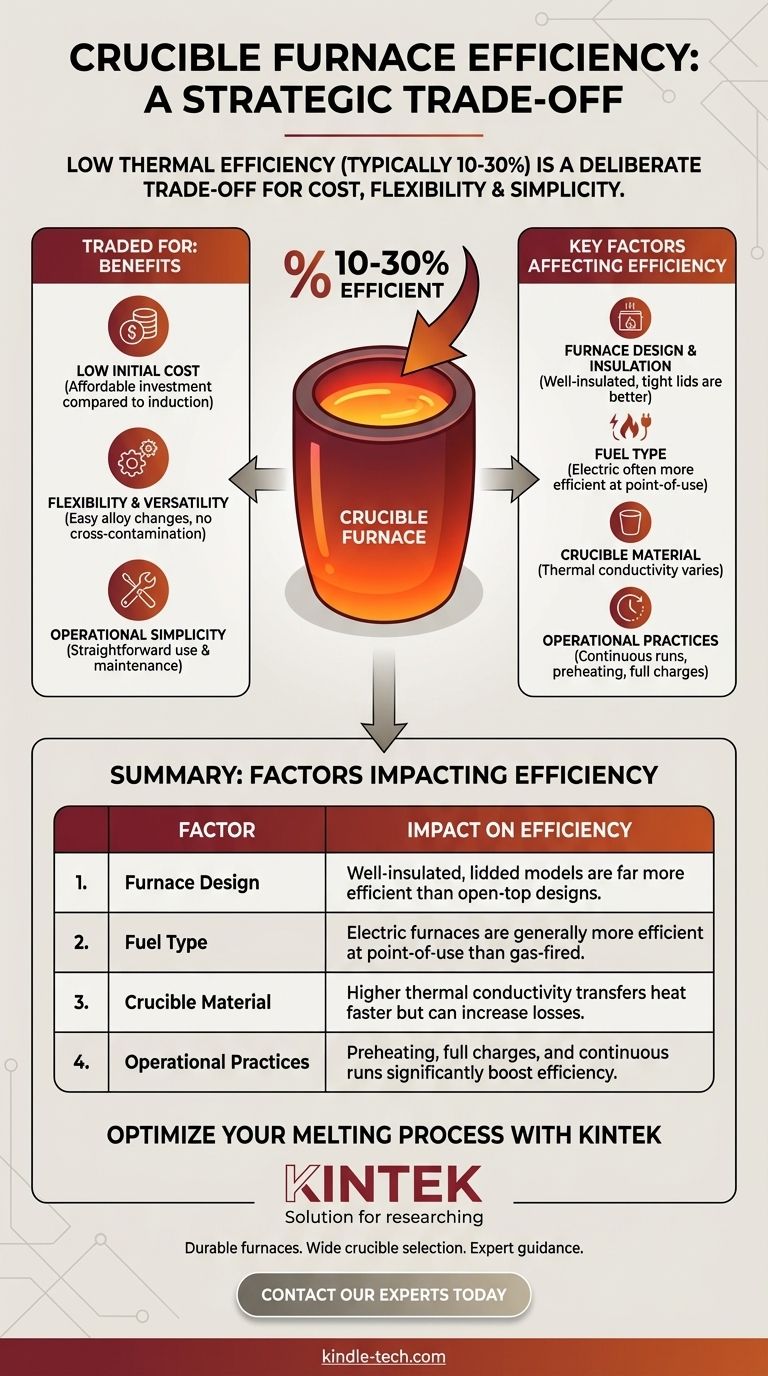

The thermal efficiency of a crucible furnace is not a single number, but rather a highly variable metric that is often quite low. While precise figures depend entirely on the specific design, fuel type, and application, many simple crucible furnaces operate in the 10-30% efficiency range. This low efficiency is a direct trade-off for their primary benefits: low initial cost, operational simplicity, and versatility.

The core issue is not the low numerical efficiency of a crucible furnace, but understanding that you are deliberately trading higher energy consumption for significant advantages in cost, flexibility, and ease of use, especially for small-scale operations.

Why Direct Efficiency Numbers are Misleading

A crucible furnace's primary function is to transfer heat from a source (gas flame or electric element) through the crucible walls and into the material charge. Inefficiency arises from heat escaping this system. Several key factors determine how much heat is lost versus how much is used productively.

The Role of Furnace Design and Fuel

The construction of the furnace itself is the largest factor. An electric resistance furnace is generally more efficient at the point of use than a gas-fired furnace, as more of the energy is converted directly to heat around the crucible.

However, heat loss through the furnace walls and lid (or lack thereof) is a massive variable. A well-insulated furnace with a tight-fitting lid will always be significantly more efficient than a basic, open-top design.

Impact of the Crucible Material

Crucibles are made from materials like graphite, silicon carbide, or clay, chosen for their ability to withstand extreme temperatures. These materials also have different thermal conductivities.

A material with higher conductivity transfers heat to the metal charge faster, but it also radiates heat outward more quickly, potentially lowering overall efficiency if the furnace body isn't well-insulated.

The Material Being Melted

Different metals require different amounts of energy to melt. The specific heat (energy to raise the temperature) and latent heat of fusion (energy to transition from solid to liquid) are unique for each material.

Melting a full crucible of aluminum, for instance, requires a different total energy input than melting the same volume of brass, directly affecting the practical efficiency of a given melt cycle.

Critical Operational Factors

How you operate the furnace dramatically impacts its real-world efficiency. A furnace running continuous melts will be far more efficient than one that is started from cold for a single melt.

Factors like preheating the crucible, ensuring a full charge, and minimizing the time the lid is open all prevent heat from being wasted and contribute to better overall performance.

Understanding the Trade-offs

The low thermal efficiency of a crucible furnace is not necessarily a flaw, but a characteristic that must be weighed against its benefits.

Efficiency vs. Initial Cost

Crucible furnaces are among the most affordable types of melting furnaces available. This low capital cost is a primary reason for their popularity. More efficient systems, such as induction furnaces, can cost many times more to purchase and install. You are trading higher operational (energy) costs for lower initial investment.

Flexibility vs. Specialization

A key advantage of a crucible furnace is its versatility. You can melt different alloys in the same furnace simply by changing the crucible, preventing cross-contamination.

Specialized, high-efficiency furnaces are often optimized for a single alloy and high-throughput production, lacking the flexibility needed for labs, artisan workshops, or small foundries.

Simplicity vs. Complexity

Crucible furnaces are straightforward to operate and maintain. The primary consumable is the crucible itself, which wears out over time. More complex systems require specialized knowledge for operation and repair, increasing overhead.

Making the Right Choice for Your Goal

Your decision should be based on your primary objective, not a single efficiency number.

- If your primary focus is low initial cost and material flexibility (e.g., for a lab, artist, or hobbyist): The low thermal efficiency is an acceptable trade-off for the furnace's affordability and versatility.

- If your primary focus is running a small foundry with varied products: The crucible furnace is an excellent choice, but invest in a well-insulated model with a good lid and temperature controls to manage energy costs.

- If your primary focus is high-volume, single-alloy production with the lowest possible cost-per-part: A crucible furnace is likely the wrong tool, and you should investigate more specialized, high-efficiency systems like induction or reverberatory furnaces.

Ultimately, choosing a crucible furnace is a strategic decision where you trade thermal efficiency for unmatched versatility and accessibility.

Summary Table:

| Factor | Impact on Efficiency |

|---|---|

| Furnace Design | Well-insulated, lidded models are far more efficient than open-top designs. |

| Fuel Type | Electric furnaces are generally more efficient at point-of-use than gas-fired. |

| Crucible Material | Higher thermal conductivity transfers heat faster but can increase losses. |

| Operational Practices | Preheating, full charges, and continuous runs significantly boost efficiency. |

Optimize Your Melting Process with KINTEK

Understanding the trade-offs of crucible furnace efficiency is the first step. The next is selecting the right equipment for your specific needs. Whether you're in a research lab, a jewelry workshop, or a small foundry, KINTEK's range of high-quality crucible furnaces and consumables is designed to balance performance, cost, and flexibility.

We provide:

- Durable, well-insulated furnaces to maximize thermal efficiency.

- A wide selection of crucibles (graphite, silicon carbide) for different materials and applications.

- Expert guidance to help you choose the perfect setup for your goals and budget.

Ready to find the ideal melting solution for your operation? Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis