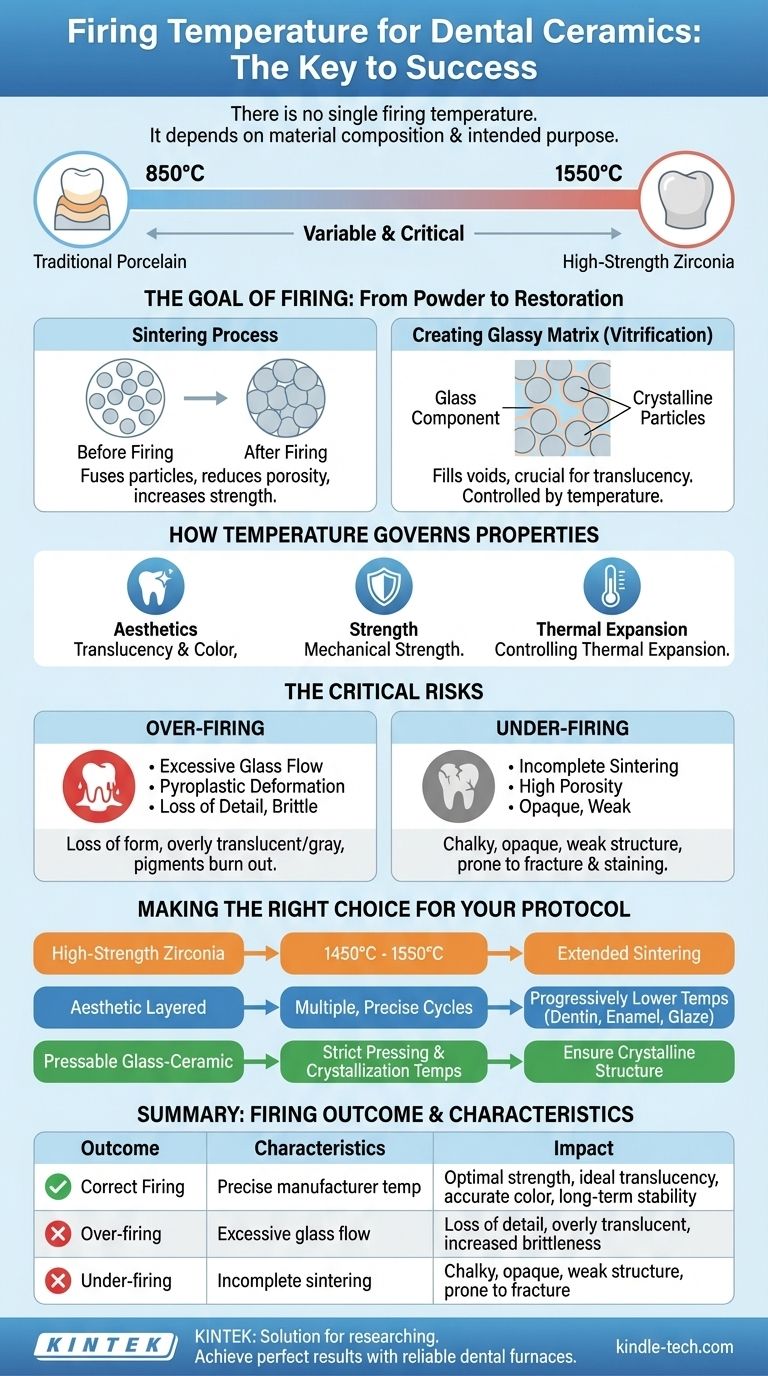

There is no single firing temperature for dental ceramics. Instead, the correct temperature is dictated entirely by the specific material's composition and intended purpose. For example, traditional feldspathic porcelains may be fired between 850°C and 1350°C, while modern high-strength zirconia requires much higher sintering temperatures, often between 1450°C and 1550°C.

The firing temperature is not a static number but a critical variable in a complex process. Achieving the precise manufacturer-recommended temperature is the determining factor in transforming ceramic powder into a restoration with the right strength, color, and translucency, directly preventing clinical failure.

The Goal of Firing: From Powder to Restoration

The purpose of firing is to convert loose ceramic particles into a dense, solid, and stable structure. This process, known as sintering, is what gives the final restoration its functional properties.

The Sintering Process

Sintering is a thermal process where ceramic particles are heated below their melting point. At these high temperatures, the particles begin to fuse at their contact points, reducing the empty space (porosity) between them and causing the material to shrink and densify.

This densification is directly responsible for the final strength of the restoration. Incomplete sintering results in a porous, weak material prone to fracture.

Creating the Glassy Matrix

Most aesthetic dental ceramics contain a glass component. During firing, this glass flows and fills the remaining voids between the crystalline particles. This process, called vitrification, is crucial for creating translucency.

The amount and flow of this glass phase are controlled by temperature. Too little flow results in an opaque, chalky appearance, while too much can create an overly translucent, gray-looking restoration.

How Temperature Governs Final Properties

Even minor deviations from the ideal firing temperature can have significant and visible consequences for the final restoration, impacting both its aesthetics and its long-term durability.

Achieving Ideal Translucency and Color

The final appearance of a ceramic crown is directly tied to how it interacts with light. This is governed by the ratio of crystalline structures to the glassy matrix, which is set by the firing temperature.

Correct firing produces the intended level of translucency, allowing the restoration to blend naturally with adjacent teeth. As noted in clinical observations, improper temperatures can ruin this balance.

Ensuring Mechanical Strength

A properly fired ceramic has minimal internal porosity and strong bonds between its particles. This makes the material highly resistant to the forces of chewing.

Incorrect temperatures can leave the material under-sintered and weak or create internal stresses that lead to crack propagation and catastrophic failure in the patient's mouth.

Controlling Thermal Expansion

For restorations that involve layering different materials, like porcelain fused to metal (PFM), matching the coefficient of thermal expansion (CTE) is critical.

Firing temperature can alter a ceramic's CTE. A mismatch between the ceramic and the underlying substructure can cause stress upon cooling, leading to cracks or delamination.

The Critical Risks: Over-firing vs. Under-firing

Every dental ceramic has an ideal maturation temperature. Deviating above or below this point introduces distinct and predictable failures.

The Consequences of Over-firing

Heating a ceramic beyond its ideal temperature causes the glassy phase to become too fluid. This leads to a loss of form and surface detail, a phenomenon known as pyroplastic flow.

The restoration may appear overly glassy, too translucent, and often discolored as pigments can be "burned out." This excessive glass can also make the material more brittle.

The Consequences of Under-firing

Failing to reach the target temperature prevents the ceramic particles from adequately fusing. The sintering process is incomplete, leaving the material porous and weak.

An under-fired restoration will appear opaque, chalky, and lifeless because the light is scattered by the internal voids. It will also be more soluble in oral fluids and susceptible to staining and premature wear.

Making the Right Choice for Your Protocol

Your protocol must be guided by the material manufacturer's specific instructions. The goal is not to find a universal temperature but to execute the correct firing cycle for the chosen material with absolute precision.

- If your primary focus is a high-strength monolithic zirconia crown: You must use a high-temperature sintering furnace capable of reaching and holding temperatures around 1450°C to 1550°C for an extended period to achieve full densification.

- If your primary focus is a highly aesthetic layered restoration (e.g., PFM): You must execute multiple, precise firing cycles at progressively lower temperatures for dentin, enamel, and glaze layers, following the material data sheet without deviation.

- If your primary focus is a pressable glass-ceramic: You must adhere strictly to both the pressing temperature and the subsequent crystallization firing temperatures to ensure the correct crystalline structure forms, which provides the material's strength.

Mastering the firing cycle is a non-negotiable requirement for producing predictable, durable, and aesthetic dental restorations.

Summary Table:

| Firing Outcome | Key Characteristics | Impact on Restoration |

|---|---|---|

| Correct Firing | Precise manufacturer-recommended temperature | Optimal strength, ideal translucency, accurate color, long-term stability |

| Over-firing | Excessive glass flow, pyroplastic deformation | Loss of detail, overly translucent/gray appearance, increased brittleness |

| Under-firing | Incomplete sintering, high porosity | Chalky, opaque appearance, weak structure prone to fracture and staining |

Achieve Perfect Ceramic Results with Every Firing Cycle

Producing predictable, high-quality dental restorations requires absolute precision in your firing process. The right laboratory furnace is the foundation of this precision, ensuring you can consistently hit the exact temperatures required for everything from high-strength zirconia (1450-1550°C) to aesthetic layered porcelains.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. We provide reliable dental furnaces designed for accuracy and durability, helping you prevent clinical failures and achieve flawless aesthetics.

Let us help you enhance your lab's capabilities. Contact our experts today to find the perfect furnace for your specific ceramic materials and protocols.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Mesh belt controlled atmosphere furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste