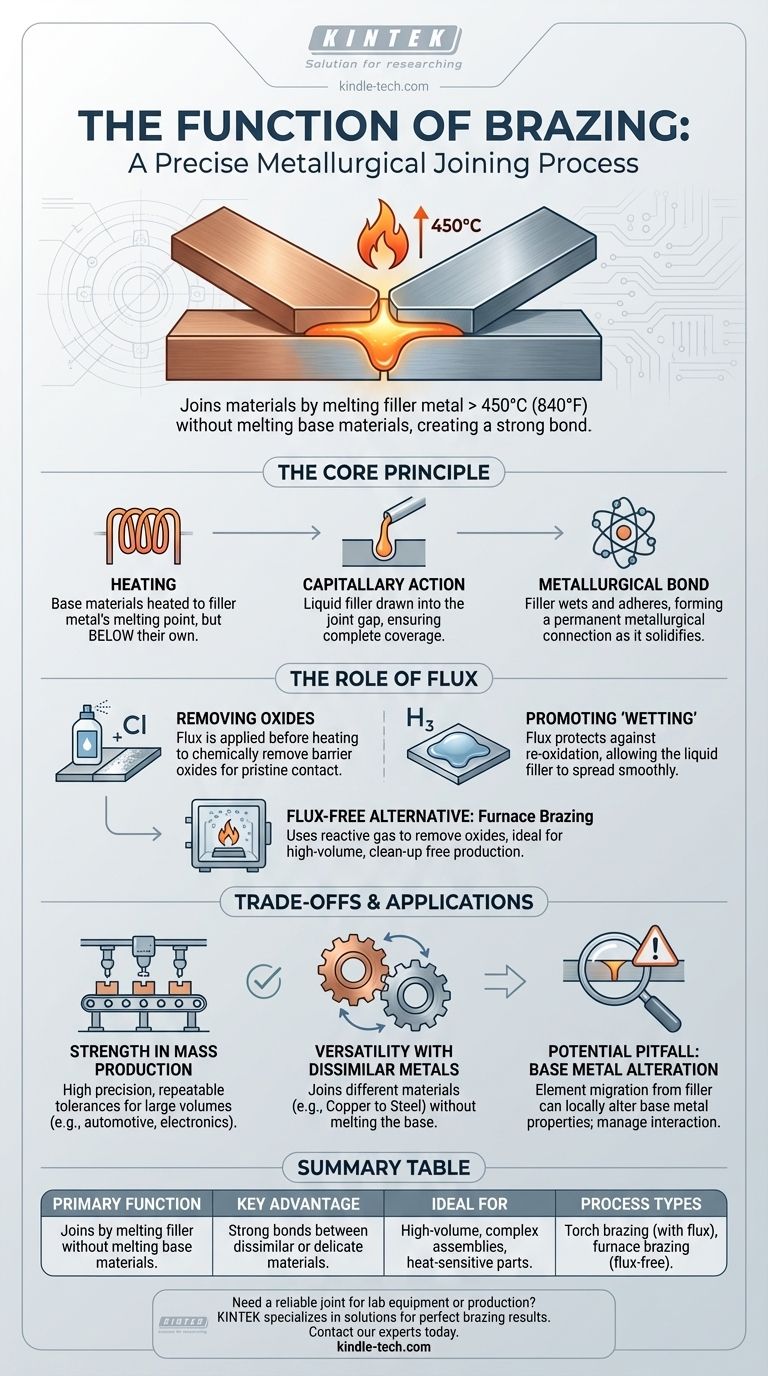

The primary function of brazing is to join two or more metal or ceramic components by heating them and melting a filler metal that flows into the joint. Unlike welding, the base materials are not melted, allowing for a strong, clean bond between dissimilar materials or delicate parts. The filler metal must have a melting point above 450°C (840°F); processes below this temperature are defined as soldering.

Brazing is not simply gluing metals together with a melted alloy; it is a metallurgical joining process that creates a permanent bond by leveraging heat, a specialized filler metal, and careful surface preparation to form a joint that is often as strong as the base materials themselves.

The Core Principle: How Brazing Works

Brazing relies on a precise interplay of heat, materials, and surface chemistry to create a robust connection between parts. Understanding these elements is key to appreciating its function.

The Role of Temperature

The entire process is defined by temperature. The base materials are heated to a temperature high enough to melt the filler metal, but always below their own melting point.

This distinction is critical. By not melting the parent materials, brazing preserves their original metallurgical properties and avoids the thermal distortion and stresses common in welding.

The Filler Metal

A specialized filler metal, or brazing alloy, is introduced to the heated joint. Because it has a lower melting point, it becomes liquid while the base metals remain solid.

Through a phenomenon called capillary action, this liquid filler is drawn into the narrow gap between the closely fitted parts, ensuring complete coverage and a void-free joint.

Creating the Metallurgical Bond

Once the filler metal flows into the joint, it begins to interact with the base materials on a molecular level. It wets and adheres to the surfaces, forming a strong, permanent metallurgical bond as it cools and solidifies.

In some cases, elements from the filler metal can migrate into the base metal. For example, silicon from a filler alloy can enrich the surface of the parent material, altering its properties locally.

The Critical Function of Flux

For a successful braze, the liquid filler metal must make direct contact with clean base metal. In most applications, this is achieved by using a chemical agent called flux.

Removing Oxides

Almost all metals form a layer of oxide on their surface when exposed to air, and this effect is accelerated by heat. Oxides act as a barrier, preventing the filler metal from bonding with the parent material.

Flux is applied to the joint area before heating. As its temperature rises, it becomes active, chemically removing these oxides and creating a pristine surface ready for bonding.

Promoting "Wetting"

Flux also protects the surface from re-oxidizing during the heating process. This allows the liquid filler metal to "wet" the surface, meaning it can spread smoothly and evenly across the entire joint.

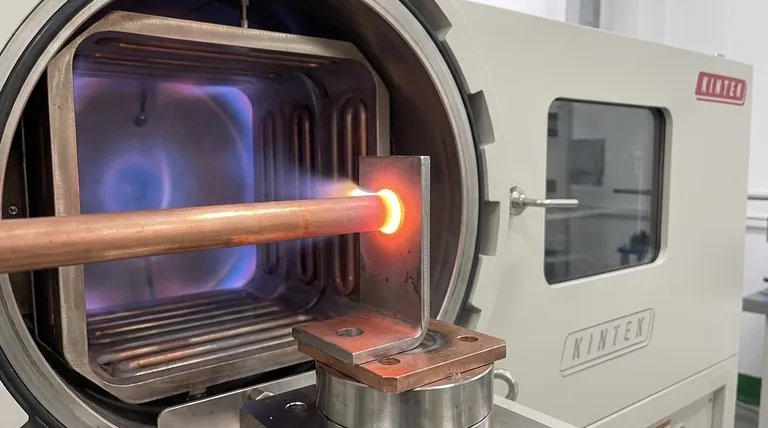

The Flux-Free Alternative: Furnace Brazing

In controlled-atmosphere furnace brazing, the role of flux is performed by the furnace environment itself. A reactive gas atmosphere removes oxides, making it an ideal process for high-volume production where flux residue cleanup is undesirable.

Understanding the Trade-offs and Applications

Brazing is a versatile and widely used process, but it's important to understand where it excels and what to watch for.

Strength in Mass Production

Automated brazing is exceptionally well-suited for mass production. Machines can be programmed to produce large volumes of parts with high precision and repeatable tolerances, making it a go-to method in automotive and electronics manufacturing.

Versatility with Different Metals

Because the base metals are not melted, brazing is an excellent method for joining dissimilar materials, such as copper to steel or aluminum to copper. This would be difficult or impossible to achieve with many conventional welding techniques.

Potential Pitfall: Base Metal Alteration

The interaction between the filler and base metal must be managed. The migration of elements, like silicon from the filler into the parent material, can locally decrease the base metal's melting point. This is a critical consideration, especially when brazing very thin parts.

Making the Right Choice for Your Application

Selecting the right joining process depends entirely on your project's goals. Brazing offers a unique set of advantages for specific challenges.

- If your primary focus is joining dissimilar or heat-sensitive materials: Brazing is a superior choice because it creates a strong bond without melting and compromising the base metals.

- If your primary focus is high-volume, precise production: Automated brazing provides the consistency, speed, and tight tolerances required for manufacturing at scale.

- If your primary focus is creating clean joints on complex assemblies: Furnace brazing offers a flux-free method that ensures thorough bonding even in intricate designs, with no post-process cleaning required.

Ultimately, brazing functions as a precise and reliable method for creating strong, permanent joints where welding is impractical or undesirable.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Joins metals/ceramics by melting a filler metal into the joint without melting the base materials. |

| Key Advantage | Creates strong bonds between dissimilar or delicate materials (e.g., copper to steel). |

| Ideal For | High-volume production, complex assemblies, and heat-sensitive applications. |

| Process Types | Torch brazing (with flux) and furnace brazing (flux-free in a controlled atmosphere). |

Need a reliable, high-quality joint for your lab equipment or production line?

Brazing is a precise solution for joining dissimilar metals and creating complex assemblies with high strength and repeatability. At KINTEK, we specialize in providing the lab equipment and consumables necessary for perfect brazing results, whether you're in R&D or manufacturing.

Contact our experts today to discuss how our solutions can enhance your brazing process and improve your product quality.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- What is the advantage of furnace brazing? Achieve Strong, Clean Joints with Minimal Distortion

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- What are the most commonly used metals in a vacuum furnace's hot zone? Discover the Key to High-Purity Processing

- Can an arc happen in a vacuum? Yes, and here's how to prevent it in your high-voltage design.