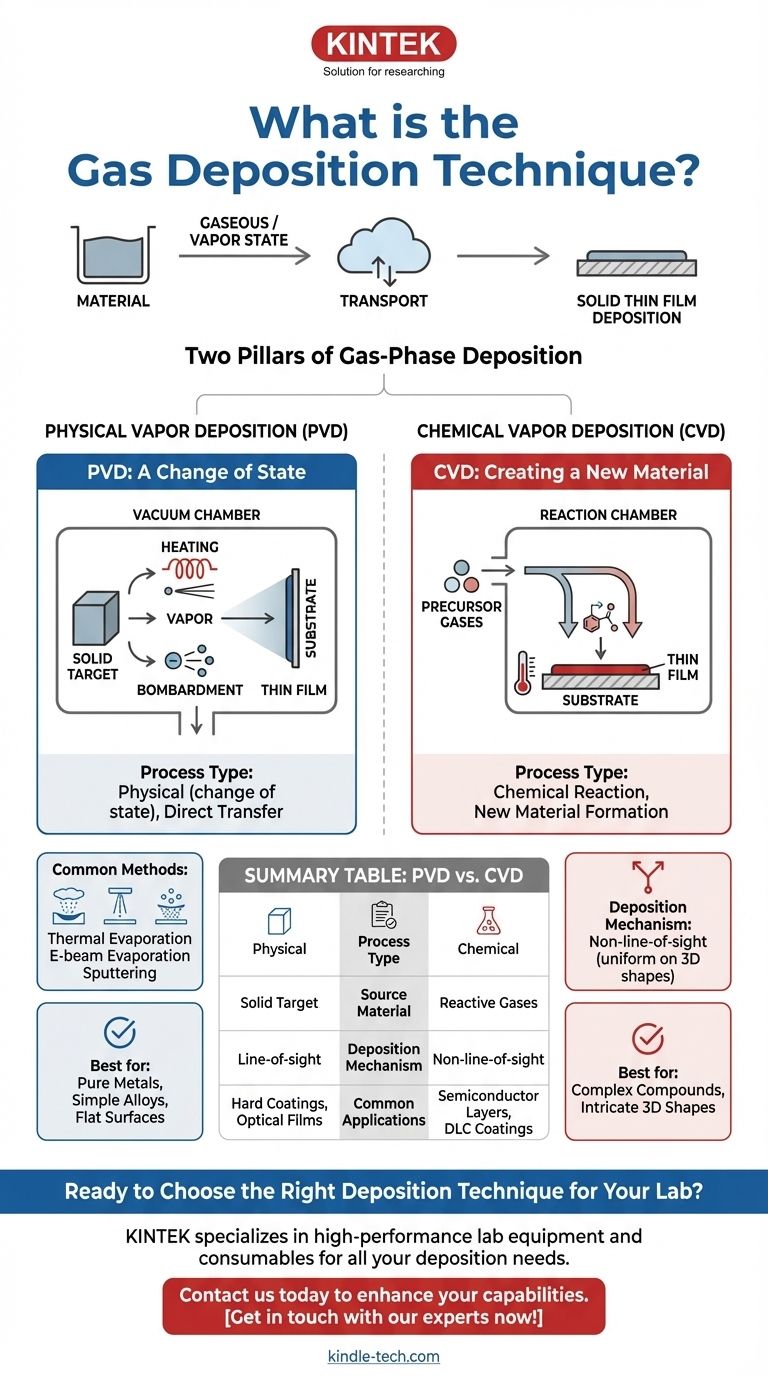

At its core, a "gas deposition technique" is any process where a material is transported in a gaseous or vapor state before being deposited as a solid thin film onto a surface. This general term is not a formal industry classification but accurately describes the two dominant families of thin-film deposition used today: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD).

The fundamental difference lies in how the material is delivered to the surface. Physical Vapor Deposition (PVD) physically transforms a solid source material into a vapor for deposition, while Chemical Vapor Deposition (CVD) uses chemical reactions between precursor gases to create a new solid material on the substrate.

The Two Pillars of Gas-Phase Deposition

While other methods like plating or spin coating exist, PVD and CVD have become the go-to techniques for high-performance applications due to their precision and versatility. Understanding them means understanding the vast majority of advanced coating technology.

Physical Vapor Deposition (PVD): A Change of State

PVD is fundamentally a physical process. A solid or liquid source material, known as the "target," is converted into a vapor within a vacuum chamber, travels across the chamber, and condenses on the substrate as a thin film.

The composition of the final film is essentially the same as the source material. It is a direct transfer, simply changing its state from solid to gas and back to solid.

There are several methods to achieve this, including:

- Thermal Evaporation: A resistive heat source heats the material until it evaporates.

- Electron-Beam Evaporation (E-beam): A high-energy electron beam is focused on the target, causing it to melt and evaporate. This is common for dense, temperature-resistant coatings in aerospace.

- Sputtering: (Not in references, but a key PVD type) High-energy ions bombard the target, physically knocking atoms off its surface.

Chemical Vapor Deposition (CVD): Creating a New Material

CVD is a chemical process. One or more volatile precursor gases are introduced into a reaction chamber. These gases decompose and react on or near a heated substrate, forming a completely new solid material that deposits onto the surface.

Unlike PVD, the deposited film is the product of a chemical reaction, not the source material itself. For example, you might react silane gas (SiH₄) and ammonia gas (NH₃) to create a silicon nitride (Si₃N₄) film, a hard ceramic material.

Understanding the Core Differences

The choice between PVD and CVD depends entirely on the desired material, the geometry of the part being coated, and the required properties of the film.

The Source Material

In PVD, the source is a solid target of the exact material you want to deposit (e.g., a block of pure titanium).

In CVD, the sources are reactive precursor gases that contain the atomic elements needed to synthesize the desired film on the surface.

The Deposition Mechanism

PVD is a line-of-sight process. The vaporized atoms travel in a relatively straight line from the source to the substrate.

CVD is generally not a line-of-sight process. The precursor gases can flow around complex objects, allowing for highly uniform coatings on intricate 3D surfaces.

Common Applications

PVD is widely used for applying hard, corrosion-resistant coatings on cutting tools, optical films for solar panels and semiconductors, and metallic decorative finishes.

CVD is a cornerstone of the semiconductor industry for creating the high-purity insulating and semiconducting layers that form transistors. It is also used for creating ultra-hard diamond-like carbon (DLC) coatings.

Making the Right Choice for Your Goal

Selecting the correct method requires understanding your end goal, as the fundamental principles of each technique lead to different strengths and weaknesses.

- If your primary focus is depositing a pure metal or a simple alloy onto a relatively flat surface: PVD is the most direct, efficient, and controllable method.

- If your primary focus is creating a complex compound film (like a nitride or oxide) or uniformly coating an intricate 3D shape: CVD's reactive, non-line-of-sight nature is superior.

Understanding the distinction between a physical transfer and a chemical reaction is the key to mastering deposition technology.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (change of state) | Chemical (reaction-based) |

| Source Material | Solid target (e.g., pure metal) | Reactive precursor gases |

| Deposition Mechanism | Line-of-sight | Non-line-of-sight (uniform on 3D shapes) |

| Common Applications | Hard coatings for tools, optical films, decorative finishes | Semiconductor layers, complex compound films (e.g., DLC) |

Ready to Choose the Right Deposition Technique for Your Lab?

Whether you're developing semiconductor components, creating hard coatings for tools, or need precise thin films for research, selecting the correct PVD or CVD equipment is critical for your success.

KINTEK specializes in high-performance lab equipment and consumables, providing reliable solutions for all your deposition needs. Our experts can help you navigate the complexities of PVD and CVD to find the perfect system for your application, ensuring superior film quality, process efficiency, and long-term reliability.

Contact us today to discuss your specific requirements and discover how KINTEK can enhance your laboratory's capabilities.

Get in touch with our experts now!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition