At its core, induction heating is a non-contact method that uses electromagnetic principles to generate heat directly inside an electrically conductive material. An alternating current is passed through a coil, creating a changing magnetic field that induces electrical currents—known as eddy currents—within the workpiece, causing it to rapidly heat up due to its own electrical resistance.

The fundamental advantage of induction is that the object heats itself from the inside out. This makes the process exceptionally fast, clean, and precise, as it eliminates the need for an external flame or heating element to transfer heat.

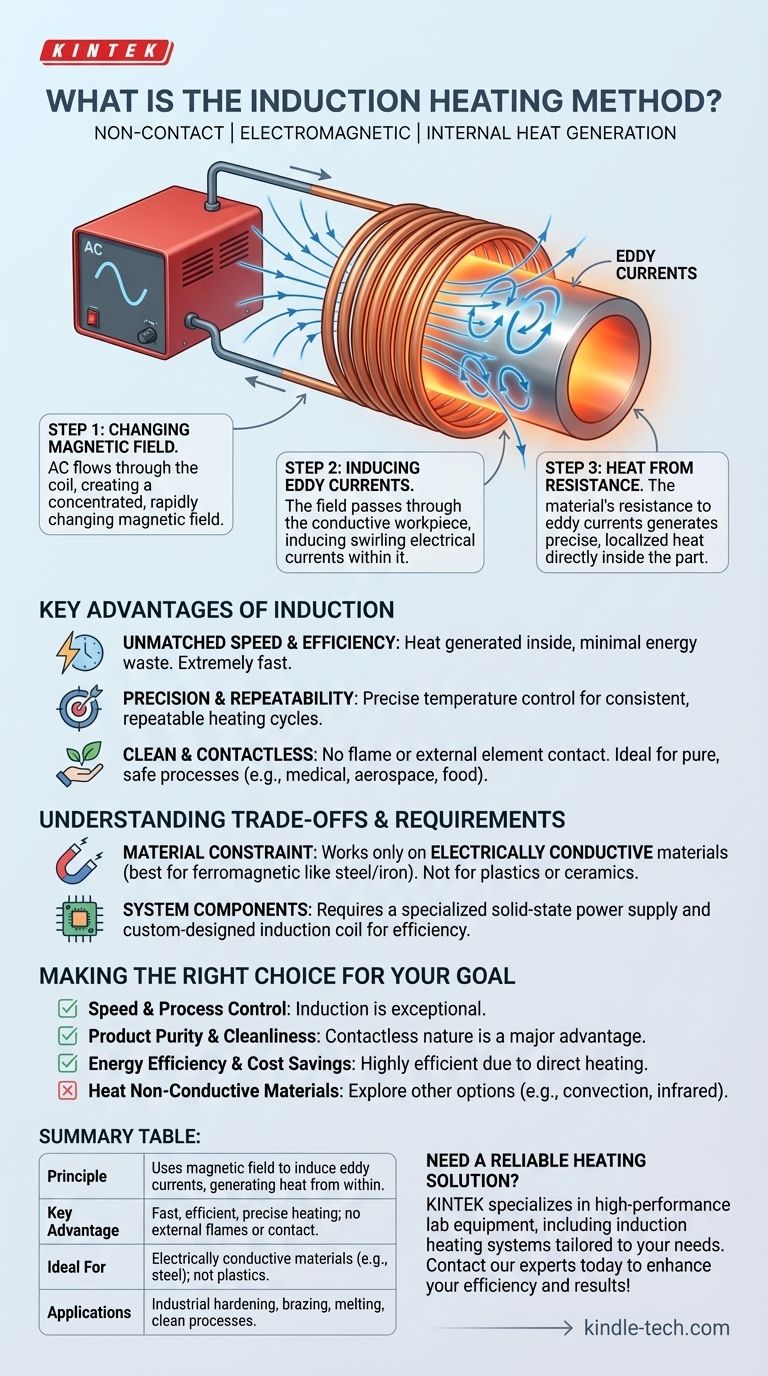

How Induction Heating Works: A Principle Breakdown

Induction heating operates on the same basic principles as a transformer. It is a clean, efficient, and highly controllable heating method that relies on a few key components and physical laws.

Step 1: The Changing Magnetic Field

The process begins with an induction heating system, which includes a high-frequency power supply and an inductor, typically a copper coil.

When an alternating current (AC) flows through this coil, it generates a concentrated and rapidly changing magnetic field around it, in accordance with Maxwell’s equations.

Step 2: Inducing Eddy Currents

An electrically conductive part, or "workpiece," is placed inside the coil without touching it. The magnetic field passes through the workpiece, inducing swirling electrical currents within it.

These induced currents are called eddy currents. They are the critical mechanism for transferring energy from the coil to the part.

Step 3: Heat from Resistance

The material of the workpiece has a natural resistance to the flow of these eddy currents. This resistance creates friction and generates precise, localized heat directly inside the part.

In essence, the workpiece becomes its own heating element, allowing it to reach high temperatures very quickly.

The Key Advantages of Induction

The unique nature of induction—generating heat internally—gives it several distinct advantages over traditional heating methods like ovens or torches.

Unmatched Speed and Efficiency

Because heat is generated inside the object itself, energy is not wasted heating the surrounding air or an external element. This direct energy transfer makes induction heating remarkably fast and energy-efficient.

Precision and Repeatability

The process is controlled by the power supply's output and frequency. This allows for extremely precise temperature control and perfectly repeatable heating cycles, which is essential for industrial automation and quality control.

A Clean and Contactless Process

The part never comes into contact with a flame or external heating tool. This contactless nature eliminates product contamination, making it ideal for applications in medicine, aerospace, and food processing. It also improves workplace safety.

Understanding the Trade-offs and Requirements

While powerful, induction heating is not a universal solution. Its effectiveness is governed by specific physical requirements that create important limitations.

The Material Constraint

Induction heating only works on materials that are electrically conductive. It is most effective on ferromagnetic materials like iron and certain steels because they have high magnetic permeability.

Materials with lower conductivity or that are non-ferrous, such as aluminum or copper, can be heated but often require different frequencies and more power. Non-conductive materials like glass, plastic, or ceramics cannot be heated directly by induction.

System Components and Coil Design

An induction system requires a specialized solid-state power supply to generate the high-frequency alternating current. The design of the induction coil is also critical.

The coil's shape and its proximity to the workpiece determine the efficiency and pattern of the heating. This often requires custom engineering for specific applications, adding to the initial system complexity and cost.

Making the Right Choice for Your Goal

Understanding the core principles of induction allows you to determine if it is the correct tool for your specific application, whether in a kitchen or a high-tech factory.

- If your primary focus is speed and process control: Induction is an exceptional choice, as the heating is nearly instantaneous and can be managed with high precision for consistent results.

- If your primary focus is product purity and cleanliness: The contactless nature of induction is a major advantage, eliminating any risk of contamination from a heat source.

- If your primary focus is energy efficiency and cost savings: Induction is highly efficient because it heats only the target part, significantly reducing wasted energy compared to ovens or furnaces.

- If you need to heat non-conductive materials: Induction is not the correct method and you should explore other options like convection, infrared, or dielectric heating.

By leveraging electromagnetism to make an object its own heat source, induction provides a level of control and efficiency that few other methods can match.

Summary Table:

| Key Aspect | Description |

|---|---|

| Principle | Uses a magnetic field to induce eddy currents, generating heat from within the material. |

| Key Advantage | Fast, efficient, and precise heating without external flames or contact. |

| Ideal For | Electrically conductive materials like steel; not suitable for plastics or ceramics. |

| Common Applications | Industrial hardening, brazing, melting, and clean processes in food/medical sectors. |

Need a reliable heating solution for your lab or production line?

Induction heating offers unmatched speed, precision, and cleanliness for conductive materials. At KINTEK, we specialize in high-performance lab equipment, including induction heating systems tailored to your specific needs—whether for research, quality control, or industrial processing.

Contact our experts today to discuss how we can enhance your efficiency and results with the right induction heating solution!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How do vacuum and heating coordinate for degassing in SiC/Al composites? Optimize Density and Interface Quality

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?

- How does vacuum hot-pressing sintering equipment solve W-Si composition segregation? Achieve Material Homogeneity

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?