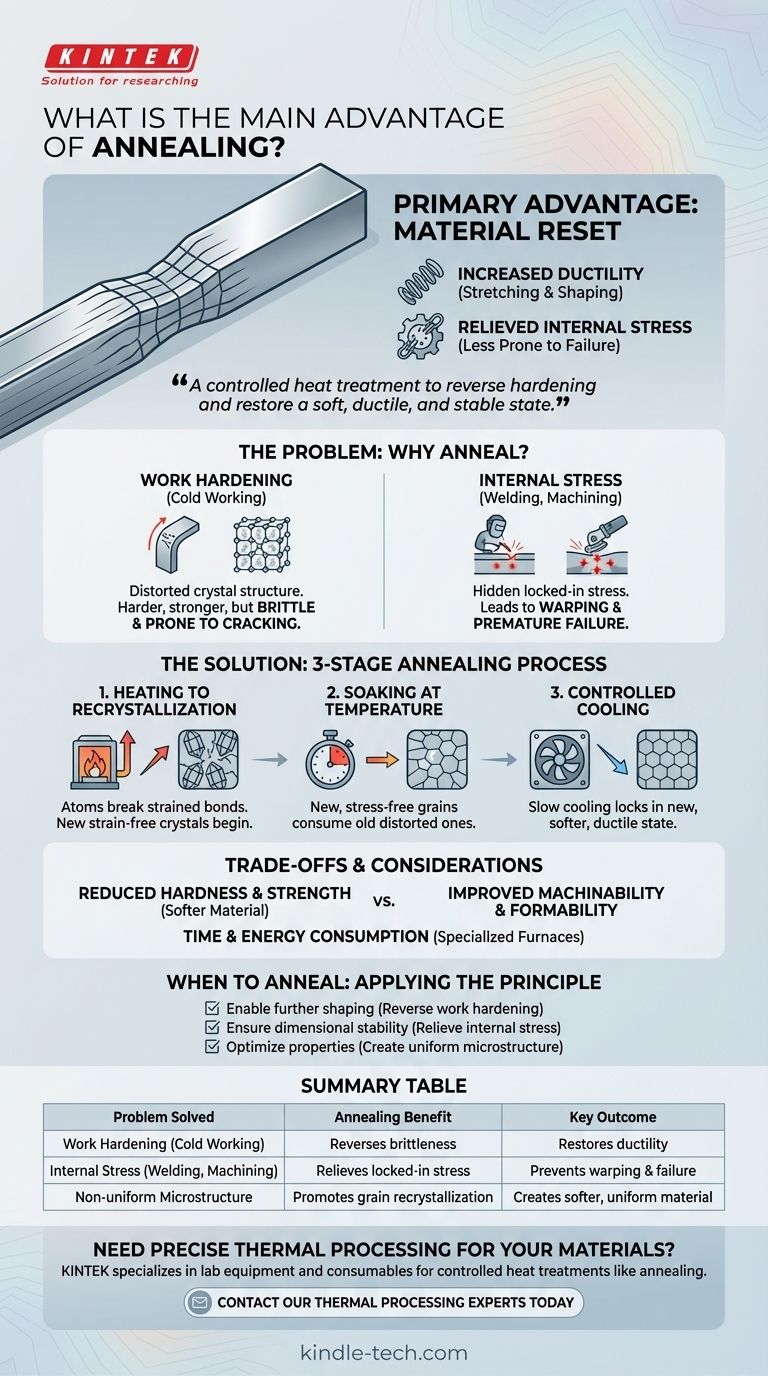

The primary advantage of annealing is to make a material more workable and less prone to failure. It achieves this by increasing its ductility (the ability to be stretched or shaped) and relieving the internal stresses that build up during manufacturing processes. This fundamental "reset" makes the material softer, more uniform, and ready for further processing.

In essence, processes like bending, machining, or welding leave a material hardened, brittle, and full of hidden stress. Annealing is the controlled heat treatment that reverses these effects, restoring the material to a soft, ductile, and stable state.

The Core Problem: Why Materials Need Annealing

Before understanding the solution, it's critical to recognize the problems that annealing solves. Manufacturing processes, while necessary, inherently alter a material's internal structure in ways that can be detrimental.

The Impact of Work Hardening

When a metal is bent, rolled, drawn, or shaped at room temperature (a process called cold working), its internal crystal structure becomes distorted and strained.

This makes the material harder and stronger, but it also significantly reduces its ductility. If you continue to work the material, it will eventually crack and fail.

The Danger of Internal Stress

Processes like machining, grinding, and welding introduce immense localized heat and mechanical force. This creates residual internal stresses locked within the material.

These hidden stresses are a significant risk. They can cause the part to warp or distort unexpectedly over time or during subsequent heat treatments, and they can lead to premature failure when the part is put into service.

How Annealing Provides the Solution

Annealing is a precise, three-stage process designed to systematically erase the damage of work hardening and internal stress by allowing the material's microstructure to reform.

Step 1: Heating to Recrystallization

The material is heated to a specific temperature, known as its recrystallization temperature. At this point, the atoms have enough energy to break their strained, distorted bonds.

This energy allows new, strain-free crystals (or grains) to begin forming within the existing stressed structure.

Step 2: Soaking at Temperature

The material is held at this temperature for a predetermined amount of time. This "soaking" period allows the new, stress-free grains to grow and consume the old, distorted ones.

The result is a more uniform and homogeneous internal structure, free from the locked-in stress introduced by prior manufacturing steps.

Step 3: Controlled Cooling

Finally, the material is cooled at a very slow and controlled rate. This slow cooling is critical to prevent new stresses from being introduced.

It allows the reformed microstructure to lock into its new, softer, and more ductile state, completing the material's "reset."

Understanding the Trade-offs

While highly effective, annealing is not a universal solution and involves important considerations. It is a deliberate engineering choice with specific consequences.

Reduced Hardness and Strength

The primary outcome of annealing is a softer material. While this improves machinability and formability, it also reduces the material's tensile strength and hardness.

If the final application requires high strength, the part may need to undergo a different heat treatment process, like hardening and tempering, after the annealing and forming steps are complete.

Time and Energy Consumption

Annealing is not an instantaneous process. Heating, soaking, and especially the slow cooling cycle can take many hours.

This requires specialized furnaces and consumes significant energy, adding both time and cost to the overall manufacturing workflow.

When to Anneal: Applying the Principle

Choosing to anneal depends entirely on the material's history and its future processing steps. Your decision should be based on a clear objective.

- If your primary focus is enabling further shaping: Use annealing to reverse the effects of work hardening, restoring ductility so the material can be bent, drawn, or formed again without cracking.

- If your primary focus is dimensional stability: Use annealing to relieve internal stresses from welding or heavy machining, preventing the part from warping during subsequent operations or in final use.

- If your primary focus is optimizing certain properties: Use annealing to create a uniform microstructure, which can improve a material's machinability or electrical conductivity.

Ultimately, annealing gives you deliberate control over a material's internal state, ensuring it is perfectly conditioned for the next step.

Summary Table:

| Problem Solved | Annealing Benefit | Key Outcome |

|---|---|---|

| Work Hardening (Cold Working) | Reverses brittleness | Restores ductility for further shaping |

| Internal Stress (Welding, Machining) | Relieves locked-in stress | Prevents warping and premature failure |

| Non-uniform Microstructure | Promotes grain recrystallization | Creates a softer, more homogeneous material |

Need precise thermal processing for your materials?

Annealing is a critical step for ensuring your materials are workable and stable. KINTEK specializes in providing the lab equipment and consumables necessary for controlled heat treatments like annealing. Our reliable furnaces and expertise help you achieve the perfect material properties for your specific application, whether you're in R&D, manufacturing, or quality control.

Contact our thermal processing experts today to discuss how we can support your laboratory's annealing needs and enhance your material processing workflow.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout