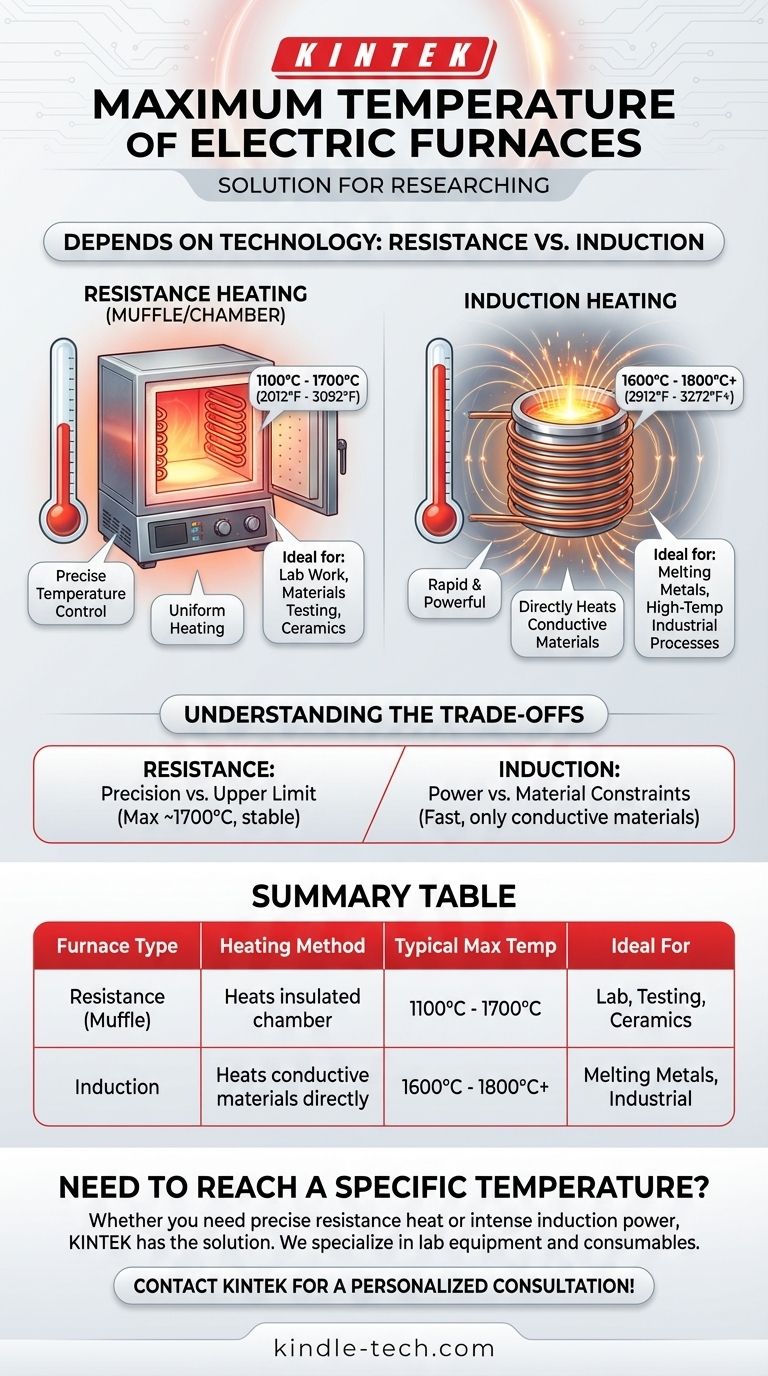

The maximum temperature of an electric furnace is not a single value, as it depends entirely on the furnace's design and heating technology. While basic electric resistance furnaces operate in the 1100°C to 1700°C (2012°F to 3092°F) range, specialized electric induction furnaces can exceed 1800°C (3272°F) for demanding industrial applications like melting metals.

The critical takeaway is that the term "electric furnace" describes two fundamentally different technologies: resistance heating and induction heating. Your required maximum temperature will dictate which technology is appropriate for your task.

The Two Core Types of Electric Furnaces

The term "electric furnace" is a broad category. The furnace's maximum temperature and ideal use case are determined by its core heating method.

Resistance Heating Furnaces (Muffle/Chamber)

This is the most common type of electric furnace for laboratory and workshop applications. It functions much like a conventional oven, but on a far more powerful scale.

An insulated chamber is lined with high-temperature heating elements. When electricity passes through these elements, they glow hot and radiate heat, uniformly raising the temperature of the entire chamber and anything inside it.

These furnaces are known for their precise temperature control and uniform heating. They are the standard for applications like chemical analysis, materials testing, and dental ceramic processing. The maximum temperature for these units typically falls between 1100°C and 1700°C.

Induction Heating Furnaces

Induction furnaces operate on a completely different principle. They do not heat the chamber; they heat the material directly.

A powerful alternating current is passed through a copper coil, which generates a strong, rapidly changing magnetic field. When a conductive material (like metal) is placed inside this coil, the magnetic field induces electrical currents within the material itself. These internal currents generate immense heat very quickly.

Because the heat is generated within the workpiece, induction furnaces can reach extremely high temperatures with great speed. They are the workhorses of the metallurgical industry, capable of reaching 1600°C to over 1800°C to melt steel and other alloys.

Understanding the Trade-offs

Choosing a furnace is not just about hitting a target temperature; it's about understanding the compromises inherent in each technology.

Resistance Furnaces: Precision vs. Upper Limit

The strength of a resistance furnace is its ability to create a stable, uniform, and precisely controlled thermal environment. However, the heating elements themselves have a melting point, which creates a practical ceiling on the furnace's maximum temperature, typically topping out around 1700°C.

Induction Furnaces: Power vs. Material Constraints

Induction heating is incredibly fast and powerful, making it unmatched for melting conductive materials. Its primary limitation is that it only works on materials that conduct electricity. It cannot be used to heat ceramics, glass, or other non-conductive materials directly.

Application Defines the Technology

A dental lab processing zirconium oxide at 1530°C requires the precise, uniform heat of a resistance muffle furnace. Conversely, a foundry melting scrap steel needs the raw, direct power of an induction furnace to reach temperatures above 1600°C.

Making the Right Choice for Your Goal

To select the correct furnace, you must first define your application and temperature requirements.

- If your primary focus is laboratory work, heat treating, or processing ceramics: A resistance (muffle) furnace is the standard choice, providing excellent control within a typical 1100°C to 1700°C range.

- If your primary focus is melting metals or achieving temperatures above 1700°C: An induction furnace is the necessary technology, delivering rapid, high-intensity heat directly to conductive materials.

By matching the heating technology to your specific task, you ensure you have the right tool for the job.

Summary Table:

| Furnace Type | Heating Method | Typical Max Temperature | Ideal For |

|---|---|---|---|

| Resistance (Muffle) Furnace | Heats an insulated chamber | 1100°C - 1700°C (2012°F - 3092°F) | Laboratory work, materials testing, ceramics processing |

| Induction Furnace | Heats conductive materials directly | 1600°C - 1800°C+ (2912°F - 3272°F+) | Melting metals, high-temperature industrial processes |

Need to Reach a Specific Temperature?

Choosing the right electric furnace is critical for your results. Whether you need the precise, uniform heat of a resistance furnace for lab work or the intense power of an induction furnace for metal melting, KINTEK has the solution.

We specialize in lab equipment and consumables, providing reliable furnaces tailored to your exact temperature and application requirements. Let our experts help you select the perfect furnace for your needs.

Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System