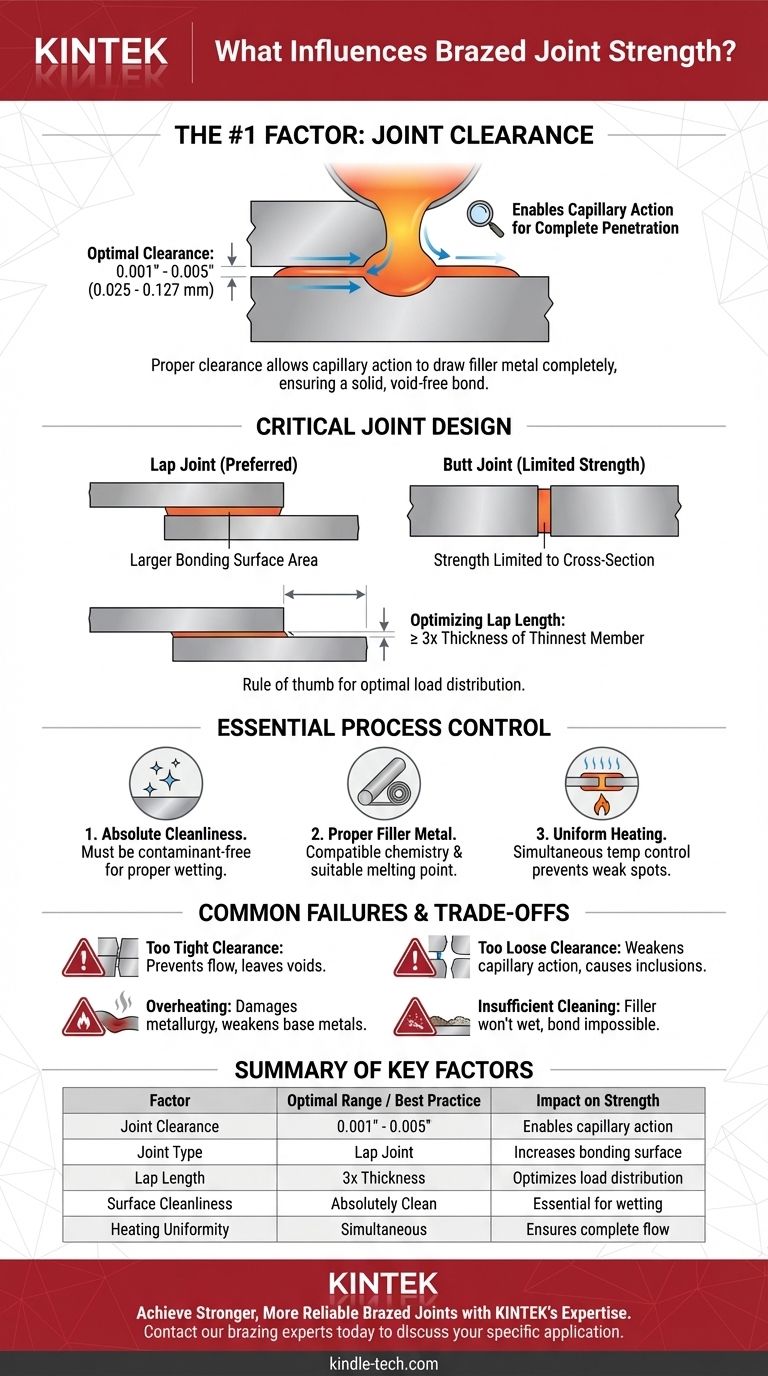

While several factors are critical, the single most important design factor influencing the strength of a brazed joint is the joint clearance. This is the physical gap between the two base materials being joined. Proper clearance is what allows capillary action to draw the molten filler metal completely into the joint, ensuring a solid, void-free bond upon cooling.

Achieving a strong brazed joint isn't about perfecting one variable, but about controlling a system of interdependent factors. Joint clearance is the foundation, but without pristine cleanliness and correct heating, even a perfect gap will result in a failed joint.

The Critical Role of Joint Design

The strength of a brazed assembly is determined before the torch is ever lit. The mechanical design of the joint itself sets the upper limit of its potential performance.

Joint Clearance: The Foundation of Strength

Joint clearance directly controls the effectiveness of capillary action. This force is responsible for pulling the liquid filler metal into the gap, even against the force of gravity.

An optimal clearance, typically between 0.001" and 0.005" (0.025 mm to 0.127 mm), ensures the filler metal can completely fill the void, creating a strong metallurgical bond with both surfaces.

Lap Joints vs. Butt Joints

For applications requiring maximum strength, a lap joint is strongly preferred over a butt joint. A butt joint's strength is limited to the cross-sectional area of the thinnest member.

A lap joint, however, creates a much larger bonding surface area. This allows the load to be distributed more effectively, ensuring the finished joint is stronger than the parent metals themselves.

Optimizing Lap Length

For a lap joint, a common rule of thumb is to make the overlap length at least three times the thickness of the thinnest member being joined.

Increasing the lap length beyond this point provides diminishing returns and can increase stress and cost without a significant gain in usable strength.

Essential Process Control Factors

A perfect design will fail if the brazing process itself is not meticulously controlled. Each of the following steps is critical to realizing the joint's designed strength.

The Principle of Cleanliness

The surfaces of the parent metals must be absolutely clean. Any contaminants—such as oils, grease, or oxides—will prevent the filler metal from "wetting" the surfaces.

If the filler metal cannot wet the material, it cannot form a metallurgical bond. This is a common and immediate cause of joint failure.

Proper Filler Metal Selection

The choice of filler metal is crucial. It must be chemically compatible with the parent metals and suitable for the intended service conditions (e.g., temperature, corrosive environment).

The filler metal's melting point must also be lower than that of the parent metals, and its flow characteristics must match the joint design.

Uniform Heating and Temperature Control

The goal is to bring both components of the assembly to the brazing temperature uniformly and simultaneously.

If one part is hotter than the other, the filler metal will flow only to the hotter side, resulting in an incomplete and weak joint. The temperature must be high enough to melt the filler but low enough to avoid damaging the parent metals.

Understanding the Trade-offs and Common Failures

Achieving a successful braze requires navigating a narrow window of ideal conditions. Deviating from these parameters is the primary source of joint weakness.

The Problem with Incorrect Clearance

A clearance that is too tight will prevent the molten filler metal from flowing into the joint, leaving voids and unbonded areas.

A clearance that is too loose weakens capillary action. This results in large voids, flux inclusions, and a finished joint made primarily of the weaker filler metal instead of a thin, strong bond line.

The Dangers of Overheating

Applying excessive heat or heating for too long can be highly destructive. It can damage the metallurgy of the parent metals, causing them to weaken or warp.

Overheating can also damage the filler metal itself, causing its constituent elements to vaporize and altering its performance characteristics.

The Impact of Insufficient Cleaning

This is an absolute failure point. If the surfaces are not clean, a metallurgical bond is impossible. The filler metal will simply ball up and refuse to flow across the joint surfaces.

Making the Right Choice for Your Application

The ideal approach depends on the specific goals of your assembly. Use these principles to guide your design and process decisions.

- If your primary focus is maximum strength: Prioritize a lap joint with an optimal overlap, maintain a precise joint clearance (0.001"-0.003"), and enforce rigorous cleaning protocols.

- If your primary focus is joining dissimilar metals: Pay special attention to filler metal selection to ensure metallurgical compatibility and consider how different rates of thermal expansion will affect joint clearance during heating.

- If your primary focus is high-volume production: Design the joint for self-location, use pre-formed filler metal rings or pastes, and develop a repeatable, automated heating process (like induction or furnace brazing).

Ultimately, a strong brazed joint is the direct product of deliberate design and disciplined process control.

Summary Table:

| Key Factor | Optimal Range / Best Practice | Impact on Joint Strength |

|---|---|---|

| Joint Clearance | 0.001" - 0.005" (0.025 - 0.127 mm) | Enables capillary action for complete filler metal penetration |

| Joint Type | Lap joint (vs. butt joint) | Increases bonding surface area for superior strength |

| Lap Length | 3x thickness of thinnest member | Optimizes load distribution without adding unnecessary stress |

| Surface Cleanliness | Absolutely contaminant-free | Essential for proper filler metal wetting and metallurgical bonding |

| Heating Uniformity | Simultaneous, uniform heating of both parts | Ensures complete filler metal flow and prevents weak spots |

Achieve stronger, more reliable brazed joints with KINTEK's expertise.

Whether you're joining dissimilar metals, optimizing for high-volume production, or seeking maximum strength, the right equipment and consumables are critical. KINTEK specializes in precision lab equipment and brazing solutions that deliver:

- Consistent, uniform heating for flawless filler metal flow

- Temperature control systems to prevent overheating and material damage

- Surface preparation tools to ensure absolute cleanliness for perfect bonding

Our team understands the delicate balance between joint design, material selection, and process control. Let us help you optimize your brazing operations for superior results.

Contact our brazing experts today to discuss your specific application and discover how KINTEK's solutions can strengthen your manufacturing process.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is a braze repair process? A Low-Heat Solution for Strong, Seamless Metal Joining

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is the basic of brazing? A Guide to Strong, Low-Heat Metal Joining