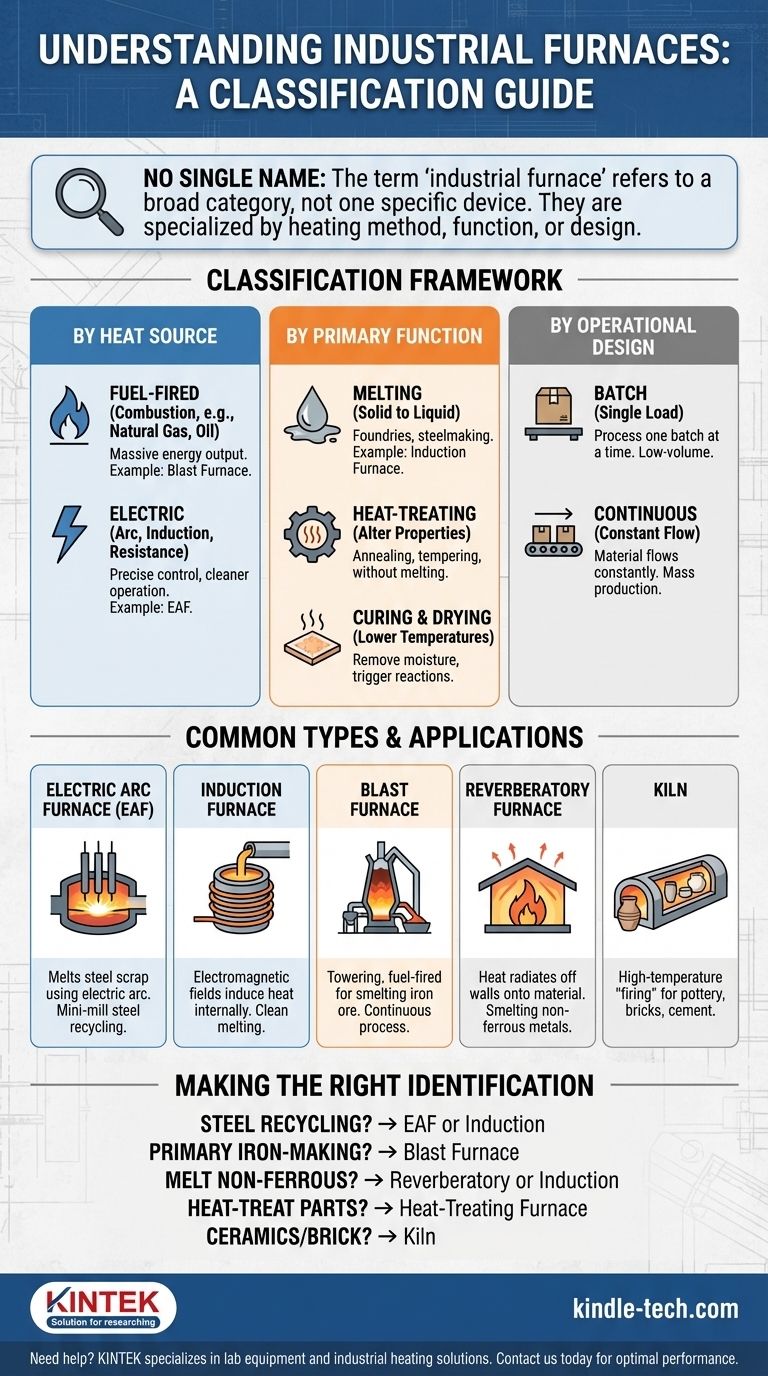

There is no single name for "the" industrial furnace because the term refers to a broad category of equipment, not one specific device. Industrial furnaces are highly specialized and are named based on their heating method, their function, or their physical design. To identify a specific furnace, you must first understand these classifications.

The key to identifying an industrial furnace is to understand its purpose and how it generates heat. Furnaces are primarily categorized by their energy source (electric vs. fuel-fired), their primary function (melting vs. heat treating), and their operational design (batch vs. continuous).

How Industrial Furnaces are Classified

To navigate the world of industrial heating, you must first understand the fundamental ways these powerful tools are categorized. This framework is essential for identifying the equipment you are looking at.

By Heat Source

The most fundamental distinction is how a furnace generates the immense heat required for industrial processes.

Fuel-Fired Furnaces use the combustion of materials like natural gas, oil, or coal. They are common in applications requiring massive energy output, like blast furnaces for iron production.

Electric Furnaces use electrical energy, often through methods like electrical arcs, induction, or resistance heating. These offer precise temperature control and cleaner operation, making them ideal for specialty metals and controlled atmospheres.

By Primary Function

A furnace's name is often directly tied to what it does to the material inside it.

Melting Furnaces, such as arc or induction furnaces, are designed to take solid materials and heat them past their melting point into a liquid state. This is fundamental to foundries and steelmaking.

Heat-Treating Furnaces are used to alter the physical and chemical properties of a material without melting it. Processes like annealing, tempering, and case hardening require this type of precise, below-melting-point heating.

Curing and Drying Ovens, which operate at lower temperatures, are used to remove moisture or trigger chemical reactions in coatings, composites, and ceramics.

By Operational Design

The way material moves through the furnace also defines its type.

Batch Furnaces process a single load or "batch" of material at a time. The material is loaded, heated through a cycle, and then removed. This is common for lower-volume or highly specialized jobs.

Continuous Furnaces process material in a constant flow. A conveyor or pusher system moves the material through different heat zones, making them highly efficient for mass production.

Common Furnace Types and Their Applications

With the classification framework in mind, we can examine some of the most common specific types you will encounter in industry.

Electric Arc Furnace (EAF)

An EAF melts steel scrap by passing an enormous electric current through graphite electrodes, creating an arc. This process is a cornerstone of modern "mini-mill" steel recycling.

Induction Furnace

This furnace uses powerful electromagnetic fields to induce eddy currents within the metal charge itself, generating heat from the inside out. It offers extremely clean and controlled melting, ideal for high-quality alloys and foundries.

Blast Furnace

A towering, fuel-fired furnace used for smelting iron ore into pig iron. It is a continuous process where coke, iron ore, and limestone are fed into the top, and molten iron and slag are tapped from the bottom.

Reverberatory Furnace

In this fuel-fired design, the flame and heat do not directly touch the material. Instead, heat radiates (reverberates) off the roof and walls onto the charge below. This is common for smelting non-ferrous metals like copper and aluminum.

Kiln

A kiln is a type of furnace used to "fire" materials like pottery, bricks, and cement. The high temperatures cause permanent chemical and physical changes, hardening the final product.

Making the Right Identification

To identify the furnace you are looking for, you need to ask the right questions about its context and purpose.

- If you are observing a steel recycling plant: You are likely looking at an Electric Arc Furnace (EAF) or an Induction Furnace.

- If you are at a primary iron-making facility: You are almost certainly looking at a massive Blast Furnace.

- If the goal is to melt aluminum, copper, or other non-ferrous metals: You may be observing a Reverberatory Furnace or a specialized Induction Furnace.

- If the purpose is to harden, soften, or stress-relieve metal parts without melting them: This is a Heat-Treating Furnace, which comes in many specific designs.

- If you are in a ceramics, brick, or cement manufacturing facility: The equipment you see is a Kiln.

Understanding these categories provides the framework needed to correctly identify and discuss any piece of industrial heating equipment.

Summary Table:

| Classification | Key Types | Primary Function |

|---|---|---|

| Heat Source | Electric, Fuel-Fired | Generate heat via electricity or combustion |

| Function | Melting, Heat-Treating, Curing | Melt materials, alter properties, or dry/cure |

| Design | Batch, Continuous | Process single loads or continuous material flow |

Need help identifying or sourcing the right industrial furnace for your application? KINTEK specializes in lab equipment and consumables, serving a wide range of laboratory and industrial heating needs. Whether you require precise heat-treating furnaces, efficient melting systems, or custom solutions, our expertise ensures you get the right equipment for optimal performance. Contact us today to discuss your specific requirements and discover how KINTEK can support your operational efficiency and success.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing