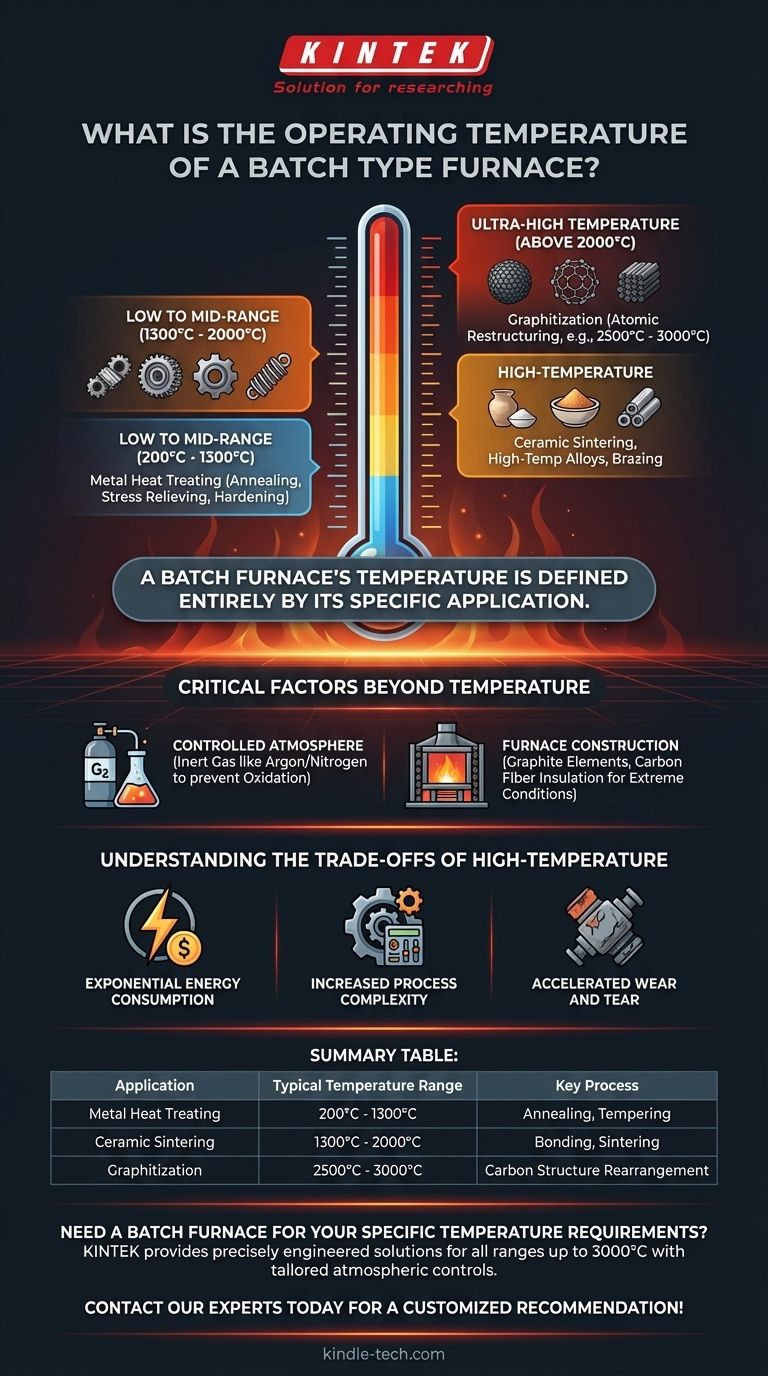

The operating temperature of a batch-type furnace is defined entirely by its specific application, ranging from a few hundred degrees for simple tempering to over 3000°C for advanced material synthesis. For example, specialized batch furnaces used for graphitization must operate at extreme temperatures, typically between 2500°C and 3000°C (4532°F and 5432°F), to restructure carbon at an atomic level.

A batch furnace has no single operating temperature. Instead, its temperature range is a critical design specification dictated by the material being processed and the desired physical or chemical transformation, from simple metal annealing to ultra-high temperature graphitization.

The Role of Temperature in Material Transformation

The purpose of a furnace is to use thermal energy to change a material's properties. The required temperature is therefore directly linked to the specific transformation needed.

Low to Mid-Range Processes (200°C - 1300°C)

Many common heat-treating processes for metals like steel and aluminum occur in this range. These temperatures are sufficient to alter the crystalline structure to achieve goals like softening (annealing), stress relieving, or hardening.

High-Temperature Processes (1300°C - 2000°C)

This range is often used for sintering ceramics, processing high-temperature alloys, and certain types of brazing. The higher energy input is needed to bond particles together or to achieve more significant changes in material structure.

Ultra-High Temperature Processes (Above 2000°C)

Processes like graphitization demand extreme temperatures. At 2500°C to 3000°C, the intense thermal energy forces the disordered atoms in a carbonaceous material to rearrange themselves into the highly ordered, layered structure of graphite.

Critical Factors Beyond Temperature

Achieving a target temperature is only one part of the equation. For a process like graphitization to succeed, other environmental factors are just as critical.

The Controlled Atmosphere

At temperatures approaching 3000°C, materials become highly reactive with oxygen. Operating in ambient air would cause the carbon material to simply burn away (oxidize).

To prevent this, these furnaces are filled with a controlled inert atmosphere, typically using argon or nitrogen gas. This non-reactive environment protects the material from oxidation and other unwanted chemical reactions, ensuring the integrity of the final product.

Furnace Construction

A furnace capable of reaching 3000°C is fundamentally different from a standard heat-treating furnace. Its construction requires specialized materials that can withstand such extreme conditions.

Heating elements are often made of graphite, and insulation consists of carbon fiber composites, as traditional metal alloys and ceramic fibers would fail catastrophically at these temperatures.

Understanding the Trade-offs of High-Temperature Operation

Pushing a furnace to such extreme temperatures introduces significant challenges and costs that must be justified by the process outcome.

Exponential Energy Consumption

The energy required to increase and maintain furnace temperature rises exponentially. The cost and infrastructure needed to power a 3000°C furnace are orders of magnitude greater than for a 1200°C furnace.

Increased Process Complexity

Managing an inert atmosphere, ensuring precise temperature uniformity, and handling materials at these heat levels requires sophisticated control systems and highly trained operators. The risk of process failure is significantly higher.

Accelerated Wear and Tear

Even with specialized materials, components within an ultra-high temperature furnace degrade much faster. This leads to higher maintenance costs, more frequent downtime, and a shorter overall lifespan for the equipment.

Making the Right Choice for Your Goal

The correct furnace is the one that meets your process requirements without excessive capability. Choosing the right temperature range is the most fundamental step.

- If your primary focus is standard metal heat treating (e.g., annealing, tempering): A furnace operating up to 1300°C is more than sufficient and will be far more cost-effective.

- If your primary focus is sintering advanced ceramics or processing refractory metals: You will require a high-temperature furnace capable of reaching 1600°C to 2000°C.

- If your primary focus is graphitization or producing advanced carbon materials: You need a specialized, ultra-high temperature batch furnace designed to operate above 2200°C with precise atmospheric controls.

Ultimately, you must match the furnace's temperature capability to the specific material transformation your process demands.

Summary Table:

| Application | Typical Temperature Range | Key Process |

|---|---|---|

| Metal Heat Treating | 200°C - 1300°C | Annealing, Tempering |

| Ceramic Sintering | 1300°C - 2000°C | Bonding, Sintering |

| Graphitization | 2500°C - 3000°C | Carbon Structure Rearrangement |

Need a Batch Furnace for Your Specific Temperature Requirements?

Whether your lab processes require standard metal heat treating or ultra-high temperature graphitization up to 3000°C, KINTEK provides precisely engineered batch furnaces with the exact temperature range and atmospheric controls your application demands. Our expertise in lab equipment ensures you get a reliable, efficient solution tailored to your material transformation goals.

Contact our experts today to discuss your specific needs and receive a customized recommendation!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Is brazing cheaper than welding? Optimize Your Metal Joining Costs for Production

- What is the mechanism of a high-temperature reaction furnace in the thermal decomposition of nickel precursors?

- What are the applications of induction hardening? Boost Component Durability for Automotive & Industrial Parts

- What is the purpose of using a high-temperature vacuum degassing furnace? Ensure High-Density ODS FeCrAl Alloy Quality

- What are the three most important factors in material heat treatment? Master Temperature, Time, and Cooling for Superior Properties

- What are the advantages of vacuum firing? Achieve Ultimate Material Purity and Performance

- What are the factors that determine the strength of a brazed joint? Achieve Maximum Strength for Your Metal Assemblies

- What are the advantages of using a vacuum drying oven for rice husk? Preserve Biomass Quality and Purity