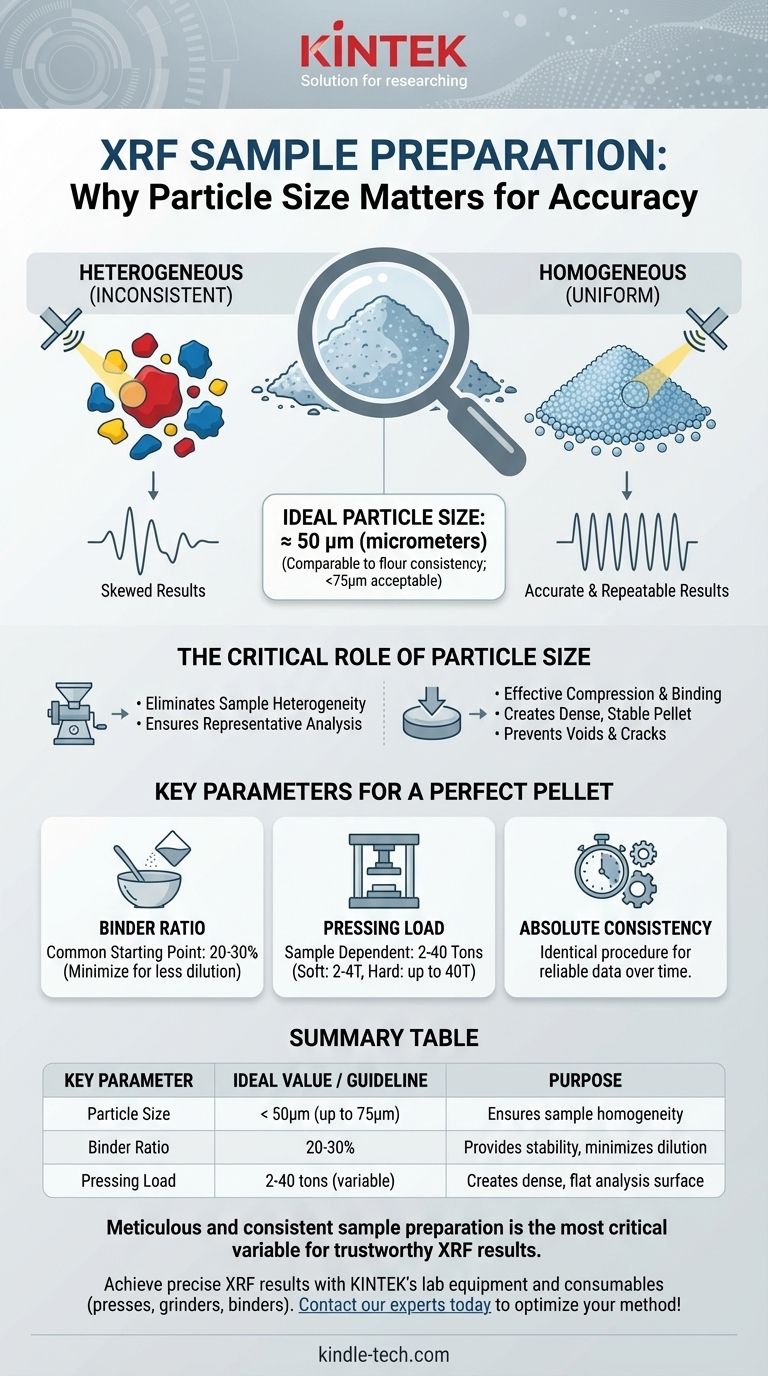

For effective X-Ray Fluorescence (XRF) analysis, the ideal sample particle size is approximately 50 micrometers (µm), which is comparable to the consistency of flour. While sizes up to 75µm can be acceptable, grinding a sample to a fine, uniform powder is a foundational step for achieving accurate and repeatable measurements.

The core principle is simple: an X-ray beam analyzes a very small surface area. If that surface contains large, inconsistent particles, the analysis will reflect that random inconsistency. A fine, homogeneous powder ensures the beam measures a true and representative average of the entire sample.

The Critical Role of Particle Size in XRF Accuracy

Preparing a sample for XRF is not just about getting it into the machine; it's about eliminating physical variables that can distort the chemical data. Particle size is arguably the most important of these variables.

Eliminating Sample Heterogeneity

XRF analysis relies on the principle of homogeneity. Large or variable particle sizes mean the sample is not uniform, or heterogeneous.

When the X-ray beam hits a heterogeneous sample, it may disproportionately excite a single large particle, skewing the results for that element. This leads to analysis errors and poor repeatability.

Ensuring Effective Compression and Binding

When creating a pressed pellet, the goal is a dense, solid disc with a perfectly flat analysis surface.

Fine, uniform particles (ideally <50µm) pack together much more effectively under pressure. This eliminates voids and creates a stable pellet that won't crumble and can withstand the vacuum conditions in some spectrometers.

Beyond Particle Size: Key Factors for a Perfect Pellet

Achieving the right particle size is necessary, but not sufficient. True analytical success requires controlling a few other key parameters to create a robust and representative sample.

The Importance of a Binder

A binder is an additive mixed with the sample powder that helps the particles adhere to one another during pressing.

A 20-30% binder-to-sample ratio is a common starting point. This provides enough strength for easy handling, but it's often possible to use less binder with experimentation to minimize sample dilution.

Applying the Correct Pressing Load

There is no universal pressing force; the ideal load depends entirely on the sample's physical properties.

A soft organic material like a food sample might only require 2-4 tons of pressure. In contrast, a hard mineral ore may need up to 40 tons to form a stable pellet.

The Ultimate Goal: Absolute Consistency

For results to be comparable over time, the preparation procedure must be identical for every sample.

This means using the same grinding time, the same binder and ratio, and the same pressing force. Consistency in preparation is the key to achieving reliable and repeatable analytical data.

Common Pitfalls to Avoid

Even with the best intentions, it's easy to introduce errors during sample preparation. Understanding the trade-offs is crucial for developing a robust method.

Inadequate Homogenization

For complex materials like ores or soils, simply grinding the sample is not enough.

These samples often require a preliminary homogenization step, such as using a jaw crusher, to break down large components before the final grinding process can create a representative powder.

Ignoring Sample Dilution

While binders are essential, they do dilute the sample, which can be an issue when measuring trace elements.

It is critical to precisely weigh both the sample and the binder for every pellet. This allows you to accurately correct for the dilution factor in your final calculations.

Making the Right Choice for Your Analysis

Your sample preparation strategy should align directly with your analytical goals and sample type.

- If your primary focus is routine quality control: Prioritize absolute consistency in grinding time, binder ratio, and pressing force to ensure your results are comparable day-to-day.

- If your primary focus is high-accuracy elemental analysis: Strive to get particles below 50µm and carefully optimize your binder ratio to minimize dilution while maintaining pellet stability.

- If you are working with complex geological materials: Acknowledge that simple grinding may not be enough; pre-crushing for homogenization is likely necessary, and the fusion method may be a more robust alternative to pressed pellets.

Ultimately, meticulous and consistent sample preparation is the most critical variable you can control to achieve trustworthy XRF results.

Summary Table:

| Key Parameter | Ideal Value / Guideline | Purpose |

|---|---|---|

| Particle Size | < 50µm (up to 75µm acceptable) | Ensures sample homogeneity for accurate analysis |

| Binder Ratio | 20-30% (common starting point) | Provides pellet stability while minimizing dilution |

| Pressing Load | 2-40 tons (sample dependent) | Creates a dense, flat pellet for analysis |

Achieve precise and reliable XRF results with KINTEK's expertise in lab equipment and consumables.

Proper sample preparation is the foundation of accurate analysis. Whether your focus is routine quality control or high-accuracy elemental measurement, having the right tools and consumables is essential. KINTEK specializes in supplying reliable laboratory equipment, including presses, grinders, and binders, to help you achieve the perfect pellet every time.

Let us help you optimize your XRF sample preparation for superior data quality. Contact our experts today to discuss your specific application and needs!

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the function of a high-energy ball mill in Fe3Al alloy prep? Achieve 7-8nm Nanocrystalline Grain Refinement

- What is the role of a ball milling system in the physical synthesis of wüstite nanoparticles? Key Mechanisms Explained

- What is the function of a Wiley grinding mill in the processing of elephant grass? Optimize Your Chemical Analysis

- What is a mixer used in a laboratory? A Guide to Vortex Mixers vs. Mixer Mills

- How do laboratory ball mills facilitate the mechanochemical synthesis of ZIF-8? Solvent-Free Synthesis Explained

- Why Use a Ball Mill for Ethanol-Based Wet Mixing of Fe-Ni/Zr2P2WO12? Achieve Homogeneous Material Dispersion

- What is the function of grinding equipment in LLZO synthesis? Maximize Conductivity via Mechanical Activation

- Does milling reduce particle size? Achieve Precise Control Over Your Material's Properties