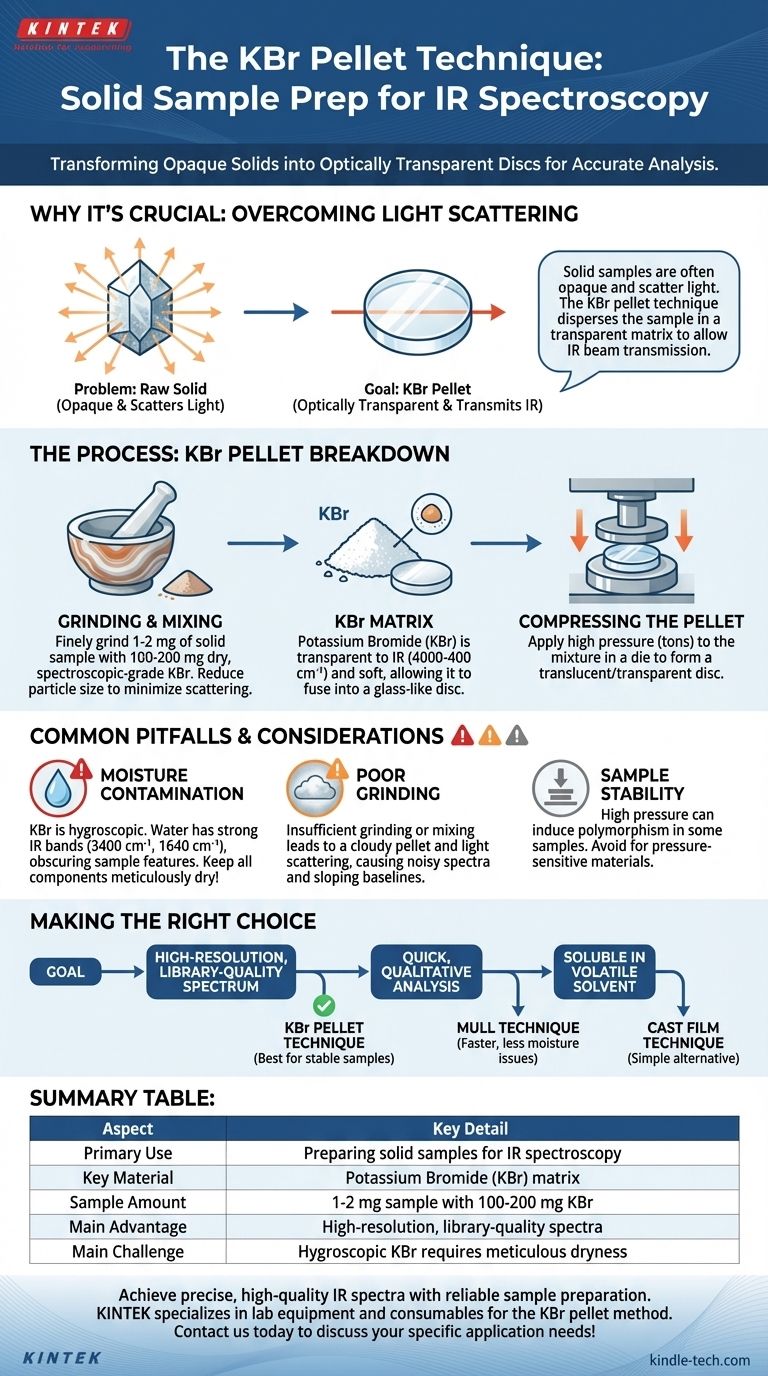

In the context of IR spectroscopy, the pellet technique is a common method for preparing solid samples for analysis. It involves finely grinding a small amount of the sample with an infrared-transparent salt, most commonly potassium bromide (KBr), and then compressing the mixture under high pressure to form a small, transparent disc.

The core challenge with solid samples is that they are typically opaque and scatter light, preventing analysis. The KBr pellet technique overcomes this by dispersing the sample within an optically clear matrix, allowing the infrared beam to pass through for measurement.

Why Solid Sample Preparation is Crucial for IR

Infrared spectroscopy works by passing a beam of IR light through a sample and measuring what light is absorbed. This fundamental requirement presents a significant challenge when dealing with solid materials.

The Problem with Raw Solids

Most solid samples, especially crystalline powders, are opaque. They scatter light in all directions rather than allowing it to pass through cleanly.

This scattering effect, known as the Christiansen effect, severely distorts the resulting spectrum, making it noisy and often uninterpretable.

The Goal: Achieving Optical Transparency

The primary objective of any solid sampling technique in IR is to reduce or eliminate light scattering.

The pellet technique achieves this by embedding the finely ground sample particles into a matrix (KBr) that has a similar refractive index, creating a homogenous medium for the light to travel through.

The KBr Pellet Technique: A Breakdown

Creating a high-quality KBr pellet is a precise process that requires careful attention to detail to avoid common issues like moisture contamination.

Step 1: Grinding and Mixing

The first step is to thoroughly grind a very small amount of your solid sample (typically 1-2 mg) with about 100-200 mg of very dry, spectroscopic-grade KBr powder.

The goal is to reduce the particle size of your sample to be smaller than the wavelength of the IR light, which minimizes scattering. This is usually done with an agate mortar and pestle.

Step 2: The KBr Matrix

Potassium bromide (KBr) is the standard choice for this technique for two key reasons.

First, it is transparent to infrared radiation across most of the useful mid-IR range (4000-400 cm⁻¹), meaning it won't contribute its own absorption bands to the spectrum. Second, it is a soft salt that flows under pressure, allowing it to form a solid, glass-like disc.

Step 3: Compressing the Pellet

The finely ground KBr/sample mixture is placed into a special pellet die.

The die is then subjected to very high pressure (several tons) using a hydraulic press. This immense pressure causes the KBr to fuse together into a translucent or transparent disc, trapping the sample material within it.

Common Pitfalls and Considerations

While powerful, the pellet technique is not foolproof. The quality of the spectrum is highly dependent on the quality of the pellet.

Pitfall: Moisture Contamination

KBr is hygroscopic, meaning it readily absorbs water from the atmosphere. This is the most common problem with this technique.

Water has very broad, strong absorption bands in the IR spectrum (around 3400 cm⁻¹ and 1640 cm⁻¹), which can easily obscure important features of your actual sample. All equipment and KBr powder must be kept meticulously dry.

Pitfall: Poor Grinding

If the sample is not ground finely enough or mixed uniformly with the KBr, the resulting pellet will be cloudy.

This cloudiness is a sign of light scattering, which will lead to a sloping baseline and a poor-quality, noisy spectrum.

Consideration: Sample Stability

The high pressure used to form the pellet can sometimes induce changes in the crystalline structure (polymorphism) of a sample, which may alter its IR spectrum. It is not suitable for materials that are unstable under pressure.

Making the Right Choice for Your Goal

The KBr pellet is often considered the gold standard for high-quality spectra, but it is not the only option. Choosing the correct technique depends on your sample and your analytical goal.

- If your primary focus is obtaining a high-resolution, library-quality spectrum: The KBr pellet technique is the best choice, provided your sample is stable and not sensitive to moisture.

- If your primary focus is a quick, qualitative analysis: The mull technique, where the solid is ground with a drop of mineral oil (Nujol), is often faster and less susceptible to moisture issues.

- If your sample can be dissolved in a volatile solvent: The cast film technique, where a solution is evaporated on a salt plate, can be an excellent and simple alternative.

Ultimately, understanding the principles behind the KBr pellet technique empowers you to produce higher quality data and correctly interpret your results.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Use | Preparing solid samples for IR spectroscopy |

| Key Material | Potassium Bromide (KBr) matrix |

| Sample Amount | 1-2 mg sample mixed with 100-200 mg KBr |

| Main Advantage | Produces high-resolution, library-quality spectra |

| Main Challenge | Hygroscopic KBr requires meticulous dryness to avoid water peaks |

Achieve precise, high-quality IR spectra with reliable sample preparation. KINTEK specializes in the lab equipment and consumables you need for techniques like the KBr pellet method. From durable pellet dies and hydraulic presses to high-purity KBr salt, we support your laboratory's success. Let our experts help you optimize your workflow. Contact us today to discuss your specific application needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy