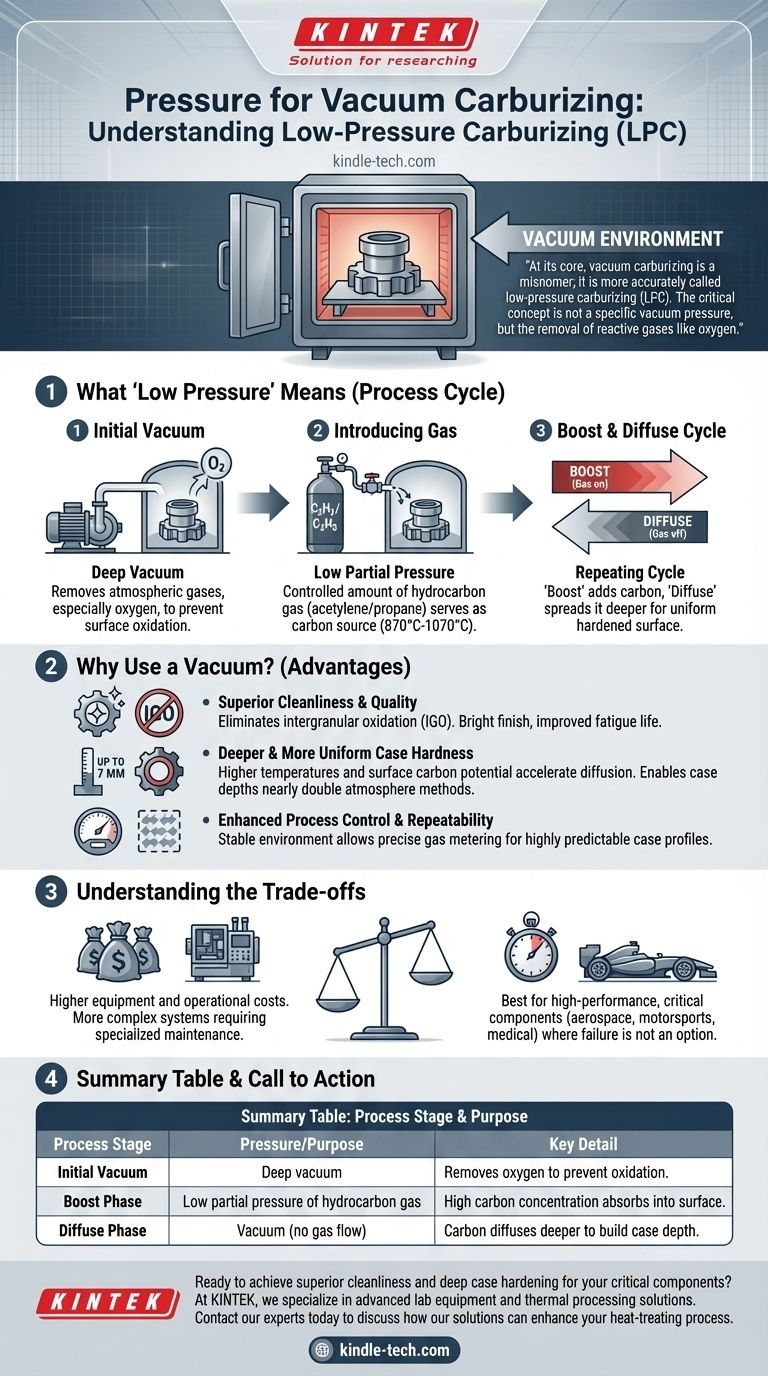

At its core, vacuum carburizing is a misnomer; it is more accurately called low-pressure carburizing (LPC). The process does not happen at a single, fixed pressure but operates in a cycle: first, a deep vacuum is established to remove atmospheric gases, and then a hydrocarbon gas is introduced at a controlled low partial pressure to serve as the carbon source.

The critical concept is not a specific vacuum pressure, but the removal of reactive gases like oxygen. This vacuum environment allows for the precise introduction of a carburizing gas at a low pressure, enabling exceptional control over the carbon diffusion process and resulting in a cleaner, more uniform hardened surface.

What "Low Pressure" Actually Means

The term "low pressure" refers to the partial pressure of the carburizing gas, not the absolute pressure within the furnace throughout the entire cycle. The process is a carefully orchestrated sequence.

The Initial Vacuum

Before carburizing begins, the furnace chamber is pumped down to create a vacuum. The primary goal is to remove atmospheric gases, especially oxygen.

This step is critical because it prevents the formation of oxides on the part's surface, which would otherwise inhibit or prevent uniform carbon absorption.

Introducing the Carburizing Gas

Once heated to temperature in the vacuum—typically between 870°C and 1,070°C (1,600°F and 1,950°F)—a small, precisely metered amount of a carburizing gas is introduced.

Commonly used gases include acetylene (C₂H₂) or propane (C₃H₈). This gas creates a low partial pressure within the chamber, providing the carbon required for the hardening process.

The Boost and Diffuse Cycle

Vacuum carburizing operates through a series of "boost" and "diffuse" steps.

- Boost: The carburizing gas is present in the chamber, and its heat-induced breakdown provides a high concentration of carbon that rapidly absorbs into the steel's surface.

- Diffuse: The gas flow is stopped, and the furnace is held at temperature. This allows the highly concentrated carbon at the surface to diffuse deeper into the part, creating the desired case depth.

This cycle is repeated until the target case depth and carbon profile are achieved, offering a level of control that is difficult to match with traditional methods.

Why Use a Vacuum for Carburizing?

The use of a vacuum environment provides several distinct metallurgical and operational advantages over traditional atmosphere-based gas carburizing.

Superior Cleanliness and Quality

By removing oxygen, vacuum carburizing completely eliminates intergranular oxidation (IGO). This results in parts with improved fatigue life and a clean, bright surface finish that often requires no subsequent cleaning operations.

Achieving Deeper and More Uniform Case Hardness

The process allows for higher carburizing temperatures (up to 1,040°C or more) than traditional methods. This high temperature, combined with a high surface carbon potential, significantly accelerates carbon diffusion.

As a result, vacuum carburizing can achieve case depths of up to 7 mm, nearly double the practical limit of atmosphere carburizing. The absence of interfering gases also ensures exceptional uniformity, even on parts with complex geometries.

Enhanced Process Control and Repeatability

The vacuum environment is inherently stable. The amount of carburizing gas can be metered with extreme precision, allowing for highly repeatable and predictable case profiles from one batch to the next.

Understanding the Trade-offs

While powerful, vacuum carburizing is not the universal solution for all heat-treating needs. It's essential to understand its context.

Equipment and Operational Costs

Vacuum furnaces represent a significantly higher capital investment than traditional atmosphere furnaces. They are also more complex systems that can require more specialized maintenance and operational knowledge.

Throughput and Cycle Times

While diffusion is faster at higher temperatures, the overall cycle time, including pump-down and cooling, must be considered. For many simple, high-volume parts, traditional atmosphere carburizing may offer higher throughput.

Application Specificity

The benefits of vacuum carburizing—superior fatigue properties, cleanliness, and precise control—are most valuable for high-performance, critical components. This includes gears for aerospace and motorsports, fuel injectors, and other parts where failure is not an option.

Making the Right Choice for Your Goal

Selecting the correct carburizing method depends entirely on the performance requirements and economic constraints of your application.

- If your primary focus is ultimate performance and material cleanliness: Vacuum carburizing is the definitive choice for critical components in industries like aerospace, medical, and high-performance automotive.

- If your primary focus is achieving very deep case depths efficiently: The ability to use higher temperatures makes vacuum carburizing the superior method for creating deep, uniform hardened layers.

- If your primary focus is cost-effective, high-volume production of non-critical parts: Traditional atmosphere carburizing remains a robust and economical solution.

Ultimately, understanding the role of pressure is key to leveraging vacuum carburizing for components that demand the highest levels of quality and performance.

Summary Table:

| Process Stage | Pressure/Purpose | Key Detail |

|---|---|---|

| Initial Vacuum | Deep vacuum | Removes oxygen to prevent surface oxidation. |

| Boost Phase | Low partial pressure of hydrocarbon gas (e.g., acetylene) | High carbon concentration absorbs into the steel surface. |

| Diffuse Phase | Vacuum (no gas flow) | Carbon diffuses deeper into the part to build case depth. |

Ready to achieve superior cleanliness and deep case hardening for your critical components?

At KINTEK, we specialize in advanced lab equipment and thermal processing solutions. Our expertise in vacuum carburizing technology can help you eliminate intergranular oxidation and achieve uniform case depths of up to 7 mm for high-performance gears, aerospace parts, and medical components.

Contact our experts today to discuss how our solutions can enhance your heat-treating process and product performance.

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is an inert condition? A Guide to Preventing Fires and Explosions

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety